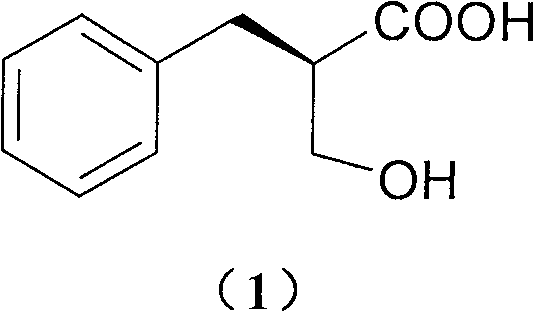

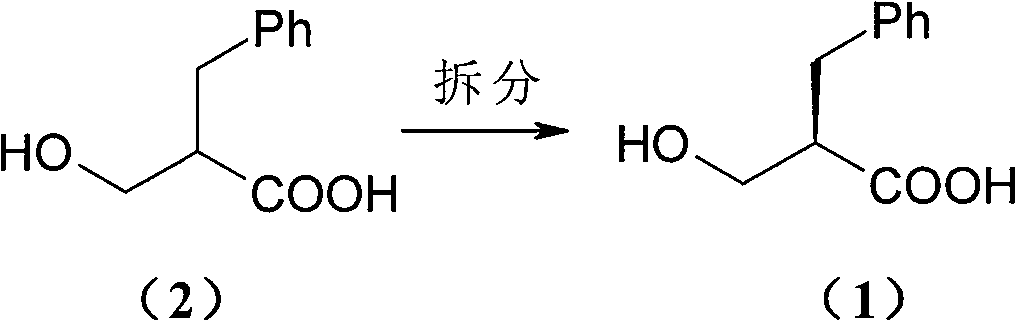

Process of resolving optical isomer of 2-hydroxmethyl-3-phenylpropionic acid

A technology of phenylpropionic acid and hydroxymethyl, which is applied in the field of splitting racemic 2-hydroxymethyl-3-phenylpropionic acid to obtain its optical isomers, which can solve the problems of high price, troublesome recycling, and separation Low efficiency and other problems, to achieve the effect of low price, easy recycling, and high disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 10.0g (55.6mmol) of 2-hydroxymethyl-3-phenylpropionic acid and 16.3g of octylglucamine were added to a 250ml single-necked bottle, and 120ml of ethanol was added, and after reflux for 10 minutes, it was naturally cooled to room temperature, left to stand for 2 days, and filtered to obtain Solid 10.0 g. Then recrystallized once with 100ml of ethanol to obtain 9.4g of solid.

[0029] Add the solid to 50ml of water, adjust the pH to 9 with 10% NaOH aqueous solution under stirring, filter, and then adjust the pH to 2 with 10% dilute hydrochloric acid in the filtrate, extract with 80ml of ethyl acetate, dry and concentrate the organic phase. Add 100ml of petroleum ether and stir to crystallize to obtain 3.6g of white solid (yield 36%, mp 68-69°C).

[0030] 1 HNMR (CDCl 3 ): 7.19-7.31 (5H, m), 5.91 (1H, br), 3.71-3.81 (2H, m), 2.92-3.12 (1H, m), 2.84-2.92 (2H, m)

[0031] [α] D 20 =+13.1° (c=1, CHCl 3 )

Embodiment 2

[0033] Add 18g (100mmol) of 2-hydroxymethyl-3-phenylpropionic acid and 29.3g (100mmol) of octylglucosamine into a 100ml single-necked bottle, add 150ml of isopropanol and 10nl of water, stir at 80°C for 10 minutes and naturally cool to Stand at room temperature for 24 hours, and filter to obtain 21.7 g of solid. Then recrystallized twice with 30ml of ethanol to obtain 19.8g of solid.

[0034] Add 50ml of water to the solid, adjust the pH to 2 with 10% dilute hydrochloric acid under stirring, filter and dry to obtain 7.2g of white solid (yield 40.3%)

Embodiment 3

[0036] Add 13.6g (75.6mmol) of 2-hydroxymethyl-3-phenylpropionic acid and 13.3g (45.4mmol) of octylglucamine into a 100ml single-necked bottle, add 50ml of methanol, reflux for 10 minutes, then cool to room temperature naturally, and let stand After 2 days, 15.6 g of solid was obtained by filtration. Then recrystallized twice with 30ml of ethanol to obtain 14.2g of solid. Add 50ml of water to the solid, adjust the pH to 2 with 10% dilute hydrochloric acid while stirring, extract with 80ml of ethyl acetate, dry over anhydrous sodium sulfate, and concentrate. Stir and crystallize with 100ml of petroleum ether to obtain 5.4g of white solid (yield 39.8%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com