Method for recovering valuable metal in electroplated mud

A technology for electroplating sludge and valuable metals, applied in the direction of improving process efficiency, can solve the problems of failure to recover metals, copper salts containing many impurities, etc., to achieve environmental benefits, social and economic benefits, and resource The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

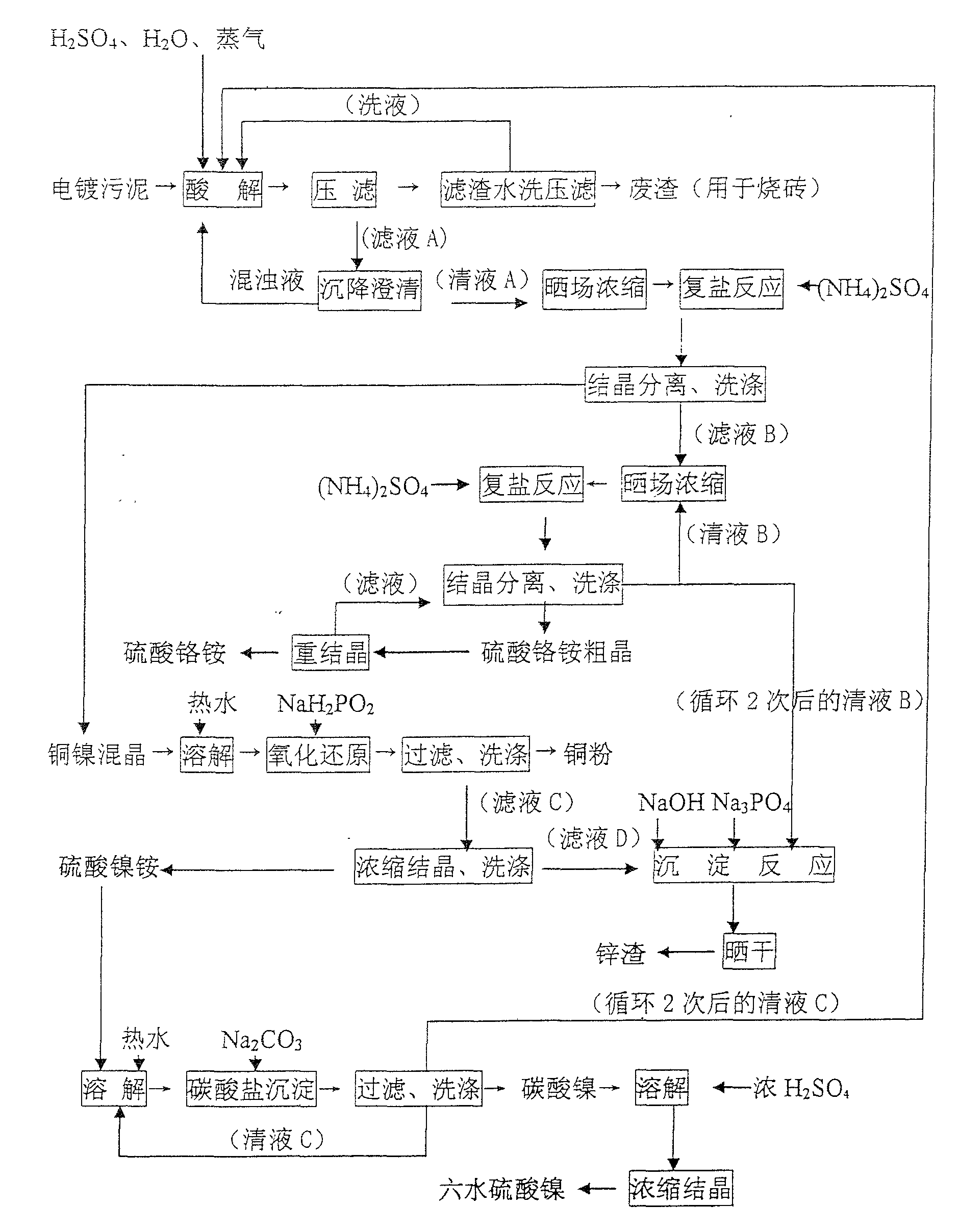

[0028] Such as figure 1 Shown is a preferred embodiment of the present invention.

[0029] The first step is acid hydrolysis. Add H to the electroplating sludge first 2 SO 4 、H 2 O etc. for acid hydrolysis.

[0030] The second step is to filter and clarify. Specifically, press filtration and then sedimentation for clarification. The filtrate A of the press filter is settled and clarified, and the clear liquid A enters the drying field in the third step to concentrate, and the cloudy solution after settling and clarification is returned to the acidolysis solution of the electroplating sludge to be repeatedly soaked and recovered, and the filter residue of the press filter is washed with water for a second time. The obtained waste residue can be used for burning bricks, and the washing solution is also returned to the acid solution of the electroplating sludge for repeated soaking and recovery to improve the metal recovery rate.

[0031] The third step is to concentrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com