Manufacturing method of high performance hollow cellulose fibre

A technology of cellulose fibers and manufacturing methods, which is applied in the manufacture of hollow filaments, single-component cellulose rayon, rayon, etc., can solve the problems of breathable and moisture permeability, thermal drape and wrinkle resistance, fiber elasticity, Poor thermal and antistatic performance, low hollowness and other problems, to achieve the effect of improved thermal and antistatic performance, poor sweat absorption and perspiration performance, and good air and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

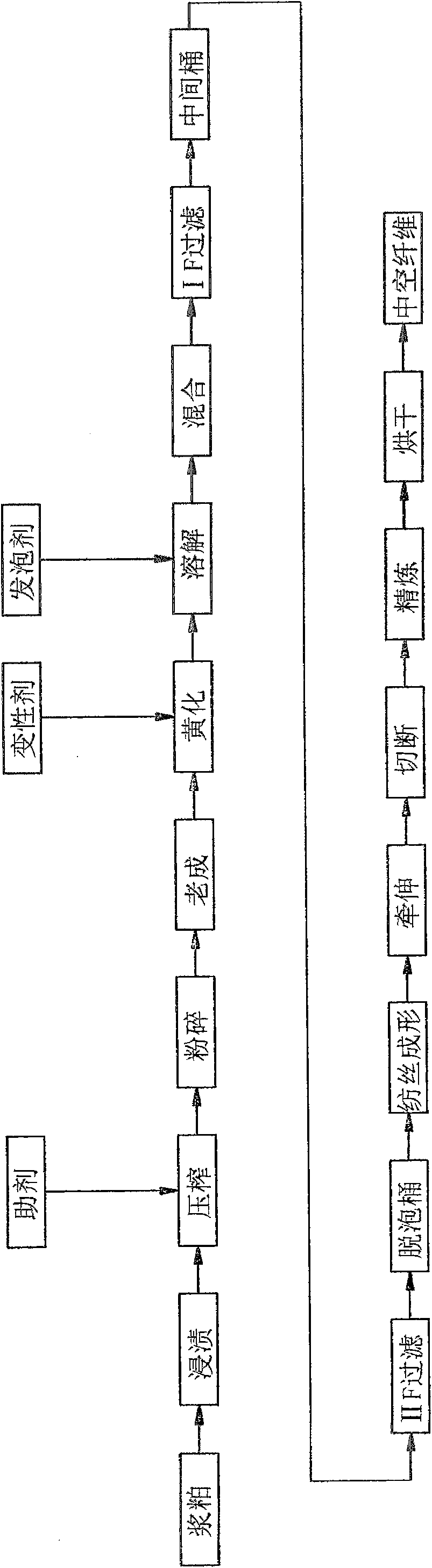

Method used

Image

Examples

Embodiment 1

[0010] 1) Selection and configuration of blowing agent:

[0011] Foaming agent: Inorganic foaming agent Na 2 CO 3 ;

[0012] The configuration of the blowing agent solution: take Na 2 CO 3 Add 3Kg of solid to 30L of softened water, stir evenly to dissolve it for later use;

[0013] 2) Preparation of spun viscose: Alkali cellulose is prepared by using cellulose cotton pulp, and the prepared alkali cellulose is added to a yellowing machine for yellowing reaction, and after yellowing for 90 minutes, add 2% ( Relative to the weight of α-cellulose) the denaturant PEG-1500 reacts uniformly until the end of yellowing. After the yellowing is over, take the prepared inorganic foaming agent solution and add it to the yellowing machine with the foaming dose of 15% relative to the weight of α-cellulose and the yellowing dissolved water. After dissolving, mix, filter, and defoam , mature and make methyl fiber be 10.5% (mass), the spinning viscose of total alkali content (sodium hydro...

Embodiment 2

[0016] 1) Selection and configuration of blowing agent:

[0017] Foaming agent: Inorganic foaming agent NaHCO 3 ;

[0018] The configuration of the blowing agent solution: take NaHCO 3 Add 2.6Kg of solid to 30L of softened water, stir evenly to dissolve it for later use;

[0019] 2) Preparation of spinning viscose: Alkali cellulose is prepared by using cellulose cotton pulp and wood pulp, and the prepared alkali cellulose is added to a yellowing machine for yellowing reaction. After yellowing for 100 minutes, add 2.5 % (α-cellulose weight) denatured agent V32 reacted uniformly until the end of yellowing. After the yellowing is finished, the prepared inorganic foaming agent solution is added to the yellowing machine together with the yellowing dissolved water at a foaming dose of 20% relative to the weight of α-cellulose. After dissolving, it is mixed, filtered, and defoamed. , maturing and making methyl fiber 8.92% (mass), total alkali content (sodium hydroxide and sodium ...

Embodiment 3

[0022] 1) Selection and configuration of blowing agent:

[0023] Foaming agent: azodicarbonamide;

[0024] The configuration of the foaming agent solution: Take 2.0Kg of the foaming agent azodicarbonamide and add it to 30L of softened water, stir evenly to dissolve it for later use;

[0025] 2) Preparation of spinning viscose: use cellulose wood pulp to prepare alkali cellulose, take the prepared alkali cellulose and add it to a yellowing machine for yellowing reaction, after yellowing for 80 minutes, add 1.8% (relative to fiber prime weight) denaturant LV3 uniform reaction until the end of yellowing. After the yellowing is over, the prepared inorganic foaming agent solution is added to the yellowing machine with the foaming amount of 8.2% relative to the weight of α-cellulose and the yellowing dissolved water. After dissolving, it is mixed, filtered, and defoamed. , mature and make methyl fiber 9.02% (mass), the spinning viscose of sodium hydroxide content 6.94%;

[0026]3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com