(meth) acrylic acid type polymer and unsaturated polyalkylene glycol type copolymer, and methods for production thereof

A technology based on polyalkylene glycol and acrylic acid, which is applied in the field of detergents and unsaturated polyalkylene glycol copolymers, and can solve the problems of poor compatibility between polymers and liquid detergents, insufficient color tone and productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0286] 156.5 g of pure water (the first charge) was placed in a separable flask with a capacity of 2.5 liters made of SUS and equipped with a reflux condenser and a stirrer, and heated to 90° C. under stirring.

[0287] Then, in the constant stirring polymerization reaction system at a temperature of about 90° C., 427.5 g (4.75 mol) of 80% acrylic acid aqueous solution (hereinafter referred to as “80% AA”) was added dropwise through separate drip nozzles. , 63.5g (0.25mol) 37% sodium acrylate aqueous solution (hereinafter abbreviated as "37%SA"), 66.7g (2.0g / mol, reduced to relative to the amount of monomer added (wherein, in this term "the added monomer Volume" refers to the total amount of all added monomers; hereinafter, its meaning is similar)) 15% sodium persulfate aqueous solution (hereinafter referred to as "15% NaPS"), and 71.4g (5.0g / mol, reduced to relative 35% sodium bisulfite aqueous solution (hereinafter referred to as "35% SBS"). The time for the dropwise additi...

Embodiment 2-14

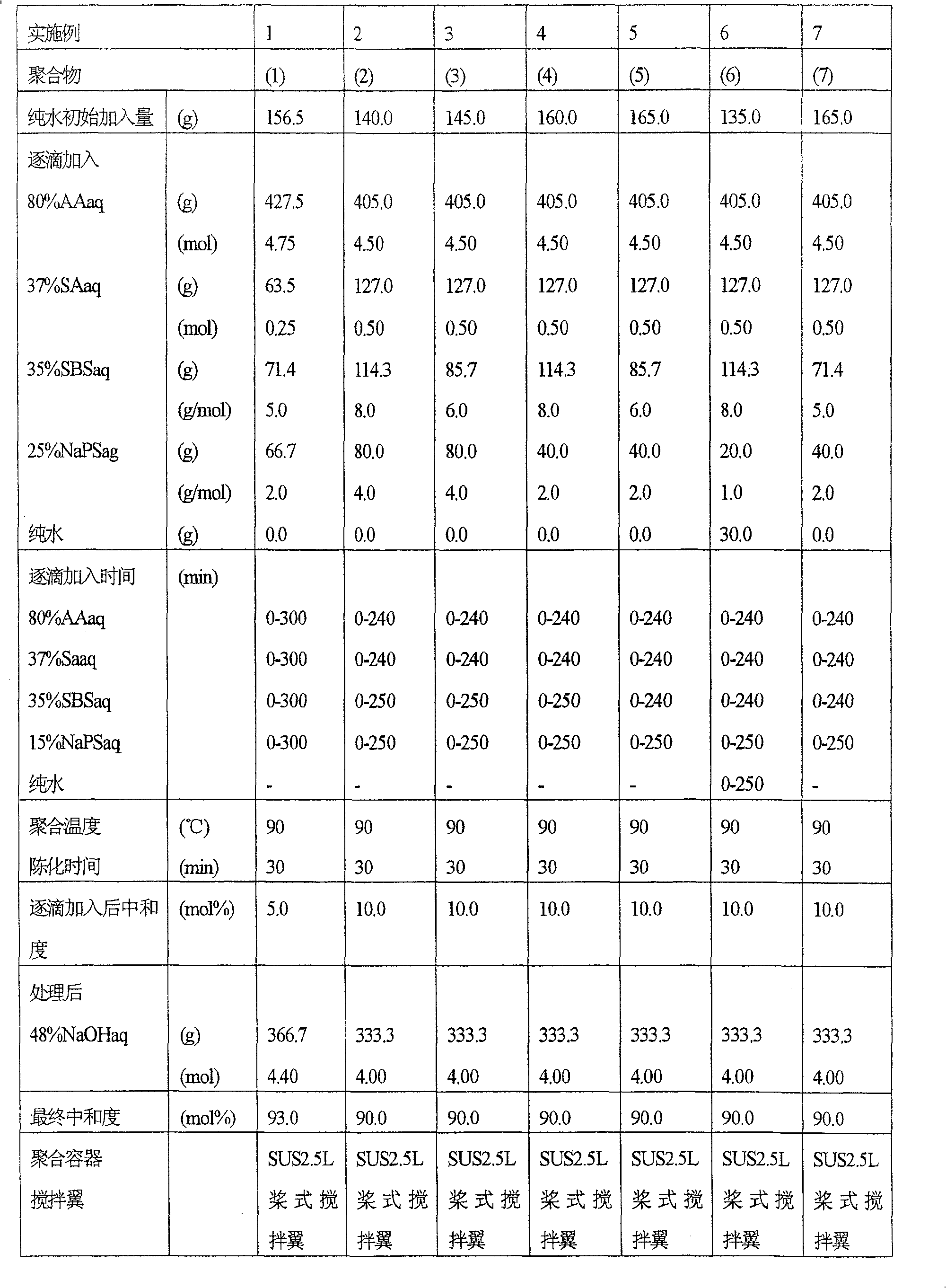

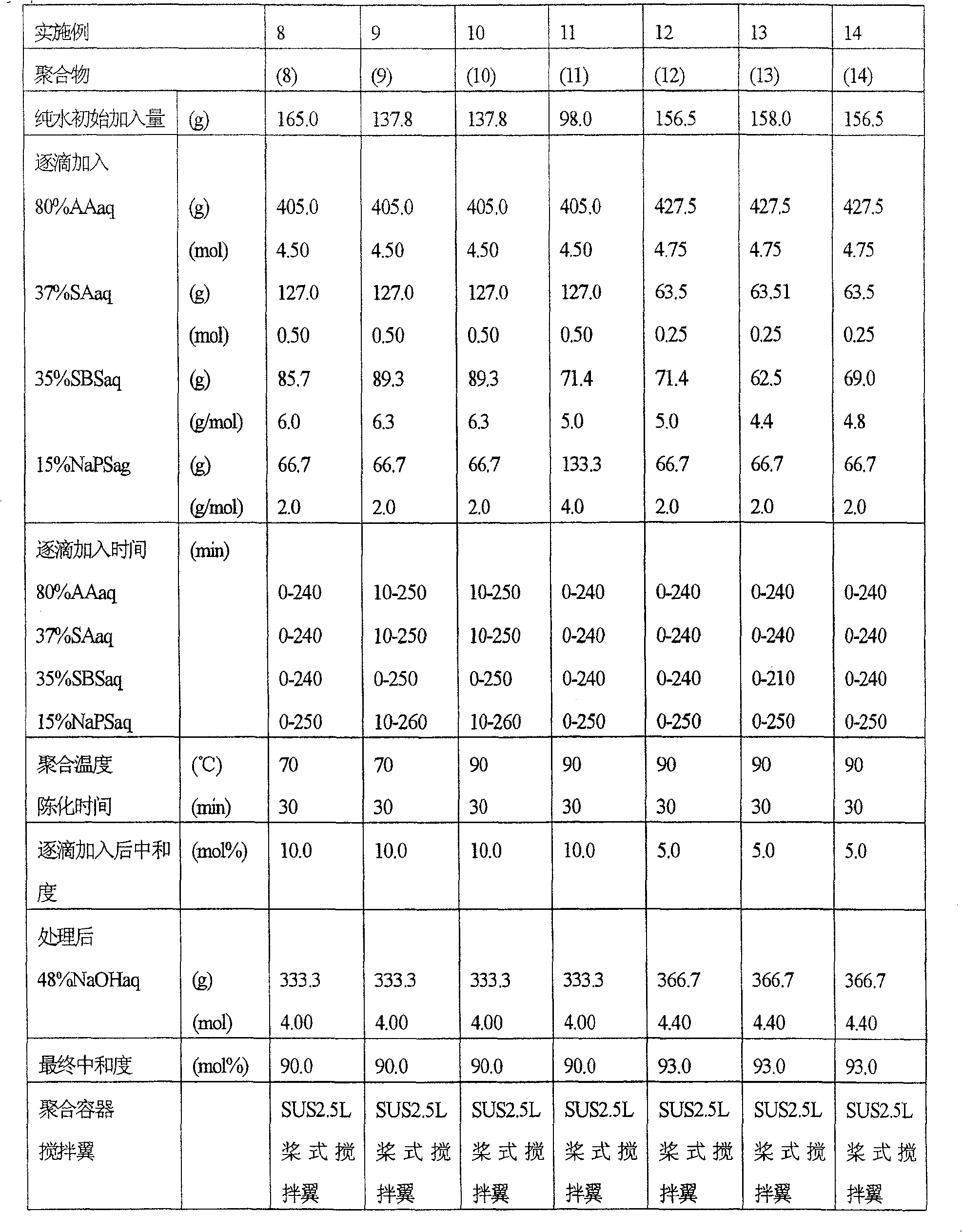

[0291] The polymkeric substance of described embodiment obtains by embodiment 1 steps. The conditions for these polymers are summarized in Tables 1 and 2 below.

[0292] The polymers (2)-(14) thus obtained were measured for their molecular weight, S value, R value, Q value, iron ion concentration, calcium binding ability, gas amount, and precipitation amount at low temperature. The results are shown in Table 11.

[0293] Table 1

[0294]

[0295] Table 2

[0296]

Embodiment 15-17

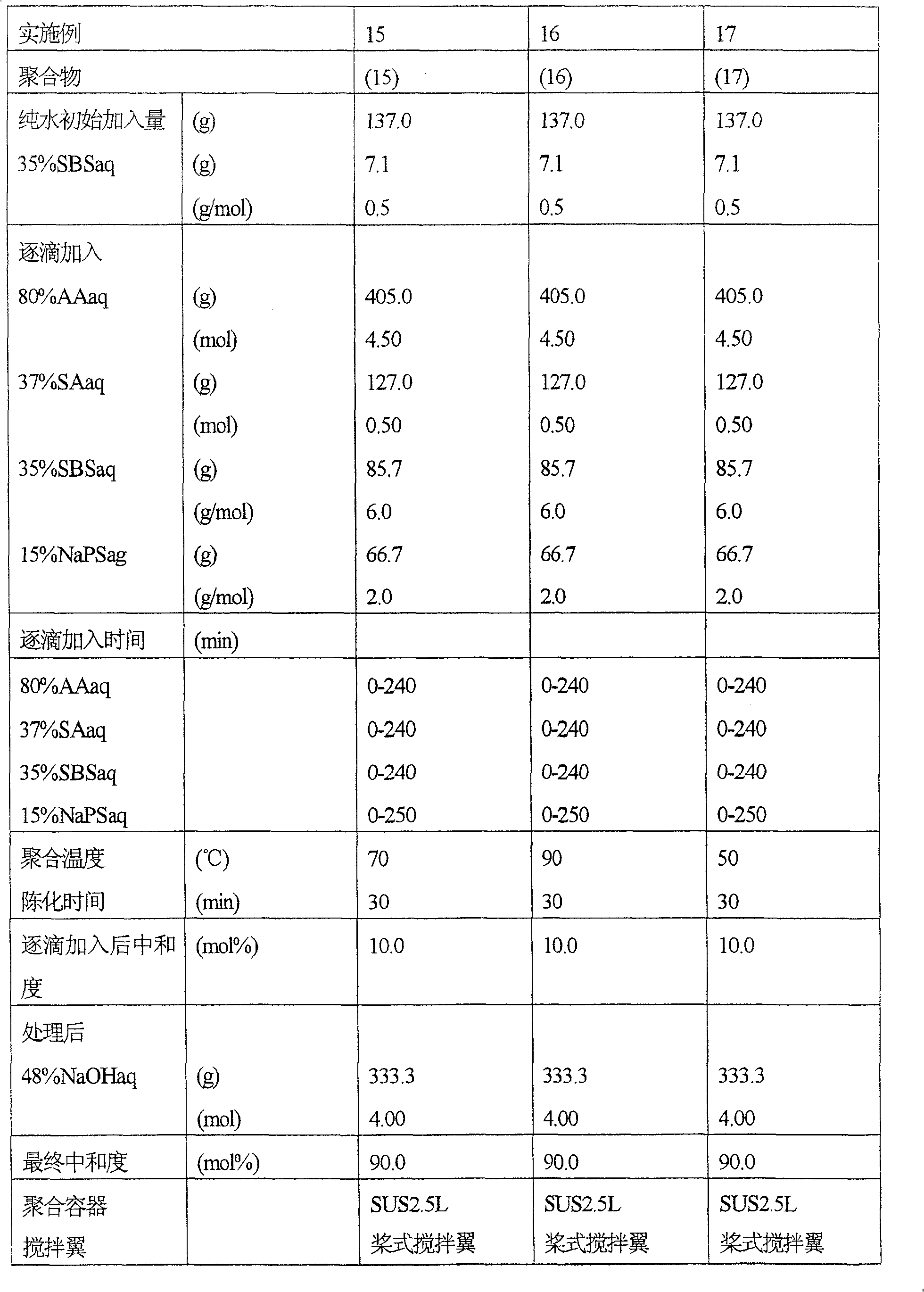

[0298] The polymkeric substance of described embodiment is obtained by embodiment 1 step, adds 7.1g (0.5g / mol, reduction to 35% SBS relative to the amount of polymer added). The conditions for these polymers are summarized in Table 3 below.

[0299] The polymers (15)-(17) thus obtained were each measured for molecular weight, S value, R value, Q value, iron ion concentration, calcium binding ability, gas amount, and precipitation amount at low temperature. The results are shown in Table 11.

[0300] table 3

[0301]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com