Ultraprecise drive mechanism

A drive mechanism, ultra-precision technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of poor resistance to external interference, low static and dynamic stiffness, etc., to achieve increased static pressure area, load bearing The effect of capacity expansion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

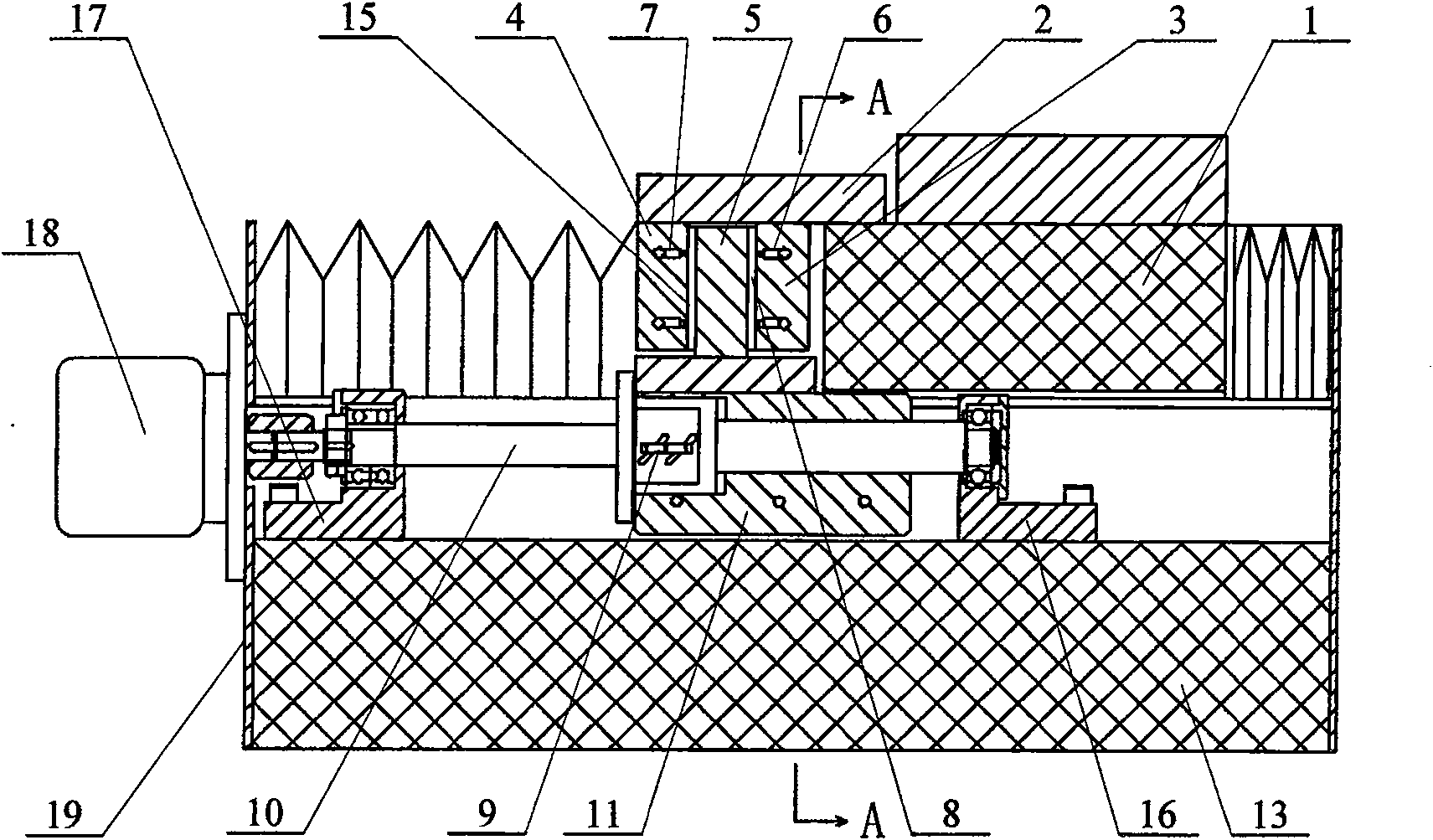

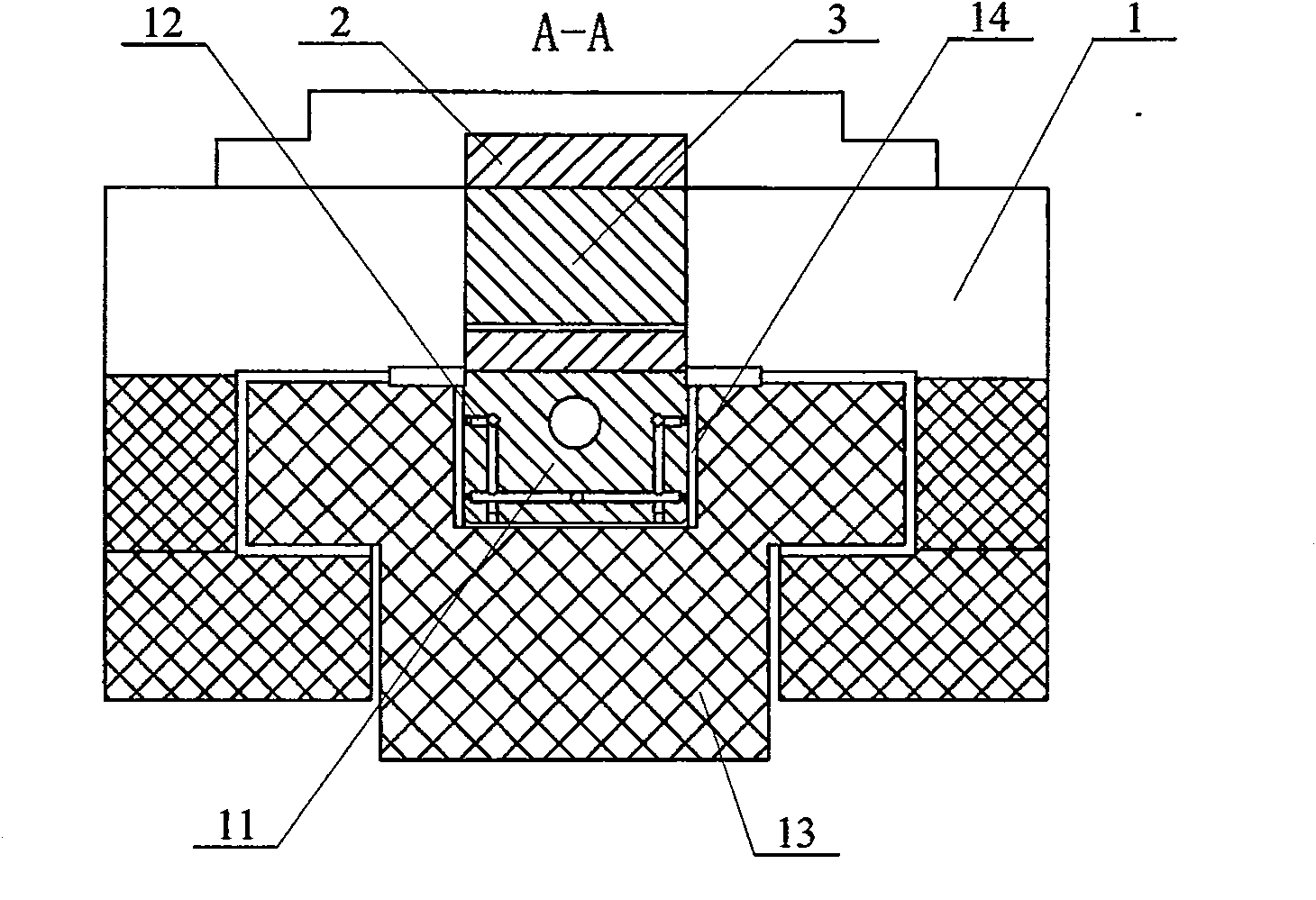

[0006] Specific implementation methods: (see figure 1 , figure 2 ) This embodiment consists of a slide plate 1, a connecting plate 2, a front push plate 3, a rear push plate 4, an intermediate push plate 5, a ball screw 9, a ball screw nut 10, an air flotation conversion block 11, a guide rail 13, and a front bracket 16 , a rear bracket 17, a motor 18 and a tailgate 19, the tailgate 19 is fixed on the rear end surface of the guide rail 13, the motor 18 is fixed on the tailgate 19, the slide plate 1 is arranged on the upper side of the guide rail 13, and the air float The conversion block 11 is arranged in the chute 14 of the guide rail 13, the front bracket 16 is arranged at the front part in the guide rail 13, the rear bracket 17 is arranged at the rear part in the guide rail 13, and the two ends of the ball screw nut 10 are connected with the front bracket 16 and the front bracket 13 respectively. The rear bracket 17 is connected, the middle section of the ball screw nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com