Inferior beer recovering machine

A recycling machine and defective product technology, used in packaging, liquid handling, emptying containers, etc., can solve the problems of wine contamination, bottle cap paint falling into wine liquid, manual opening of empty bottle caps, etc., to reduce pollution , the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

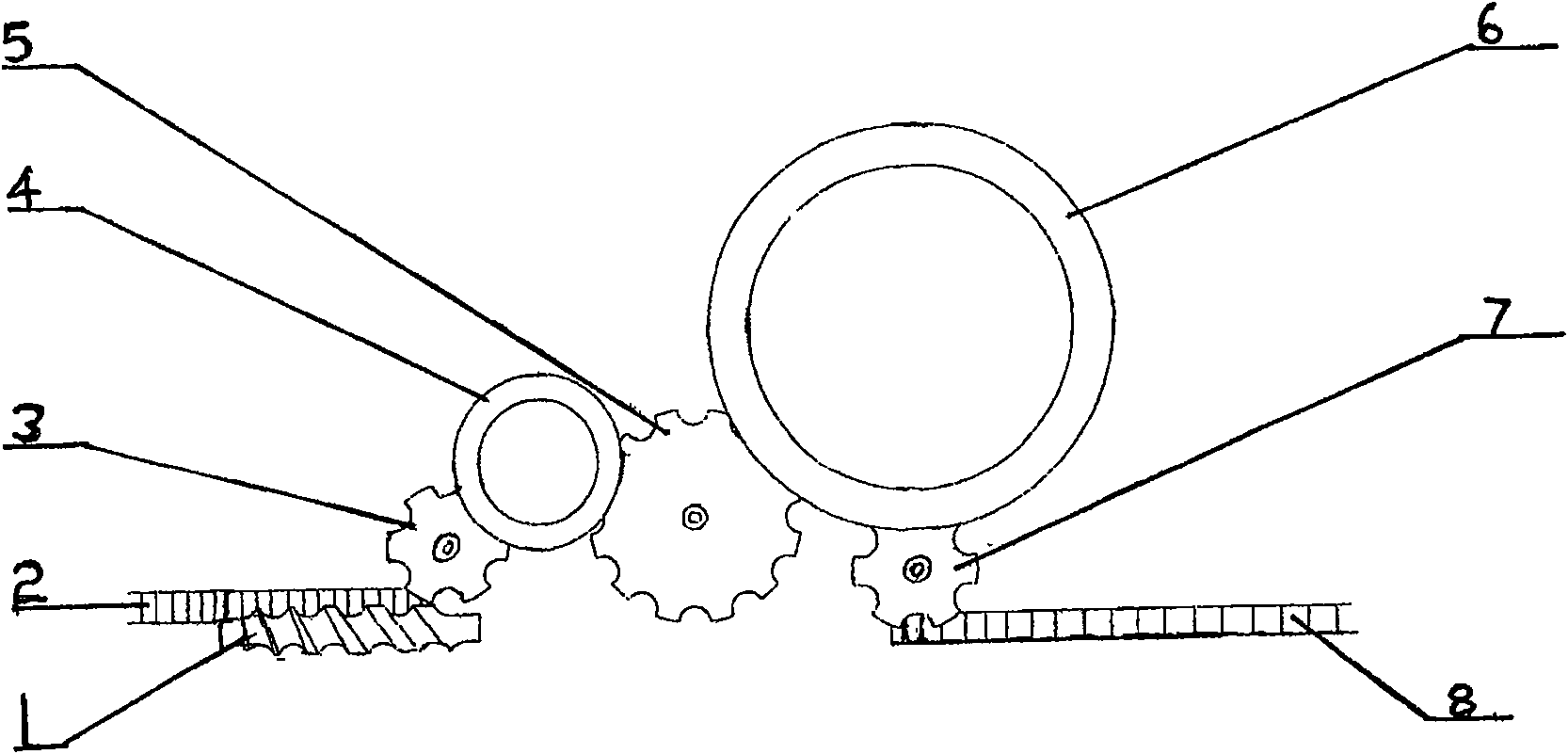

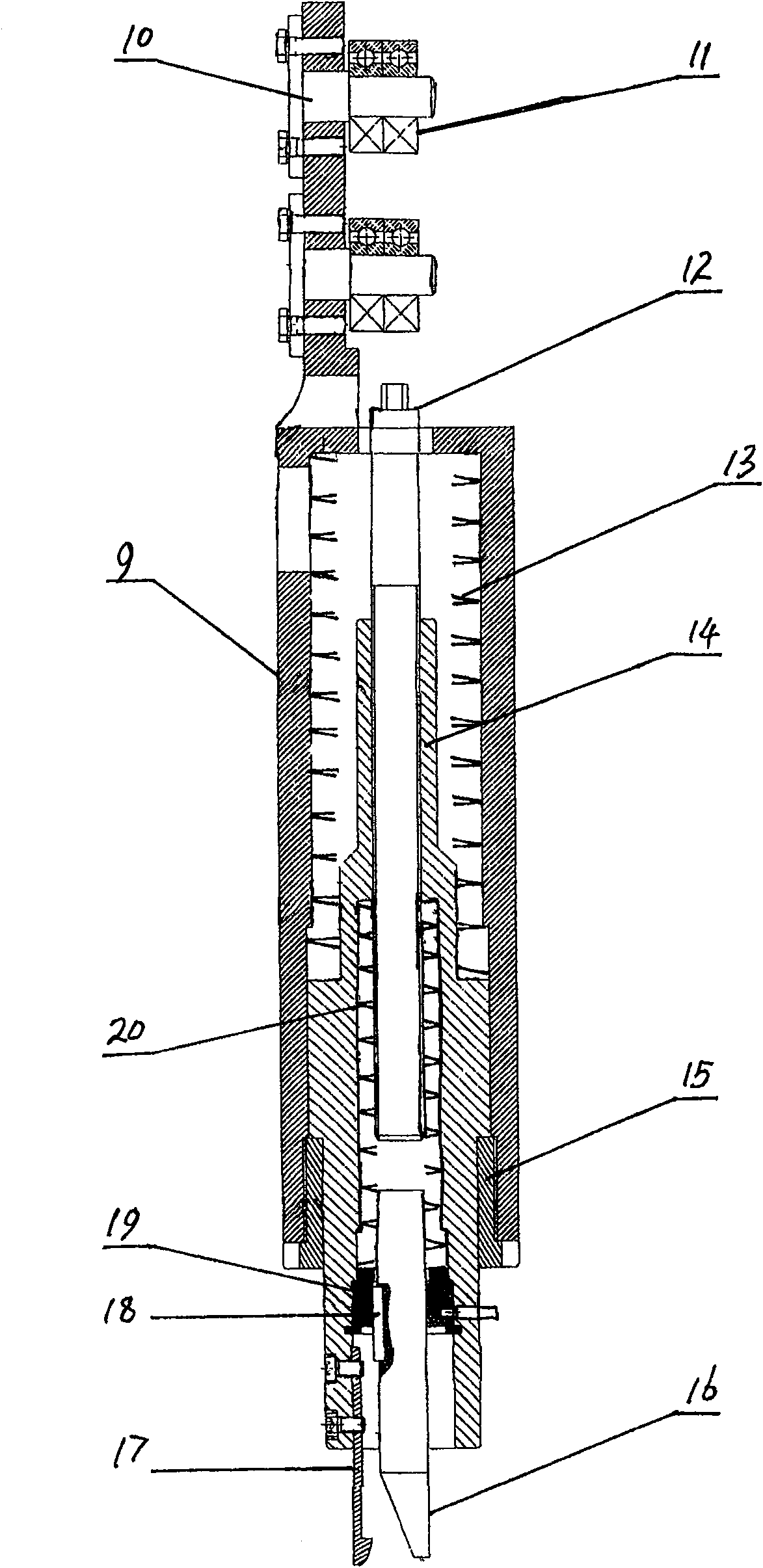

[0018] In the structure shown in the figure, the conveyor belt device 2 is used to transport beer bottles with defective products, and a bottle separating screw 1 is arranged on one side of the conveyor belt device. The bottle separating screw can separate the beer bottles to facilitate the beer bottles Enter the bottle-feeding star wheel, set the bottle-feeding star wheel 3 at the rear of the conveyor belt device, the bottle-feeding star wheel can receive the beer bottles transported from the conveyor belt device, and transport them to the automatic cap opening connected with the bottle-feeding star wheel Machine 4, a power rotating device is set on the automatic capping machine 4 to make the automatic capping machine rotate, and the automatic capping machine automatically uncaps the beer bottles during the rotation process, and an intermediary star is set on the other side of the automatic capping machine Wheel 5, a recycling machine 6 is set on the other side of the intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com