Cleaning apparatus

A cleaning device and cleaning liquid technology, which are applied in the directions of cleaning flexible articles, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as inability to use semiconductor process lithography technology, etc., and achieve suppression of precision reduction and environmental pollution. , to avoid the effect of increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

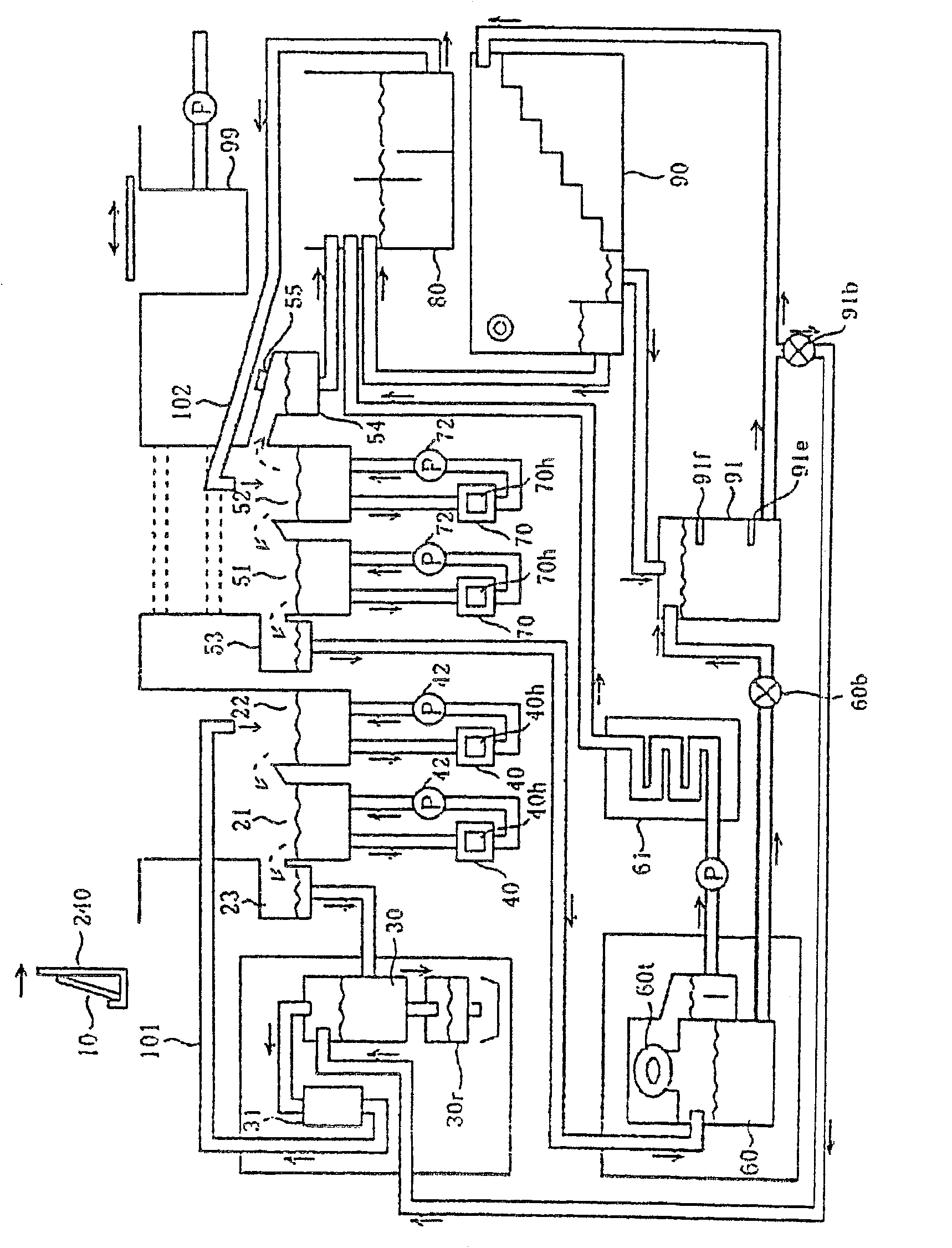

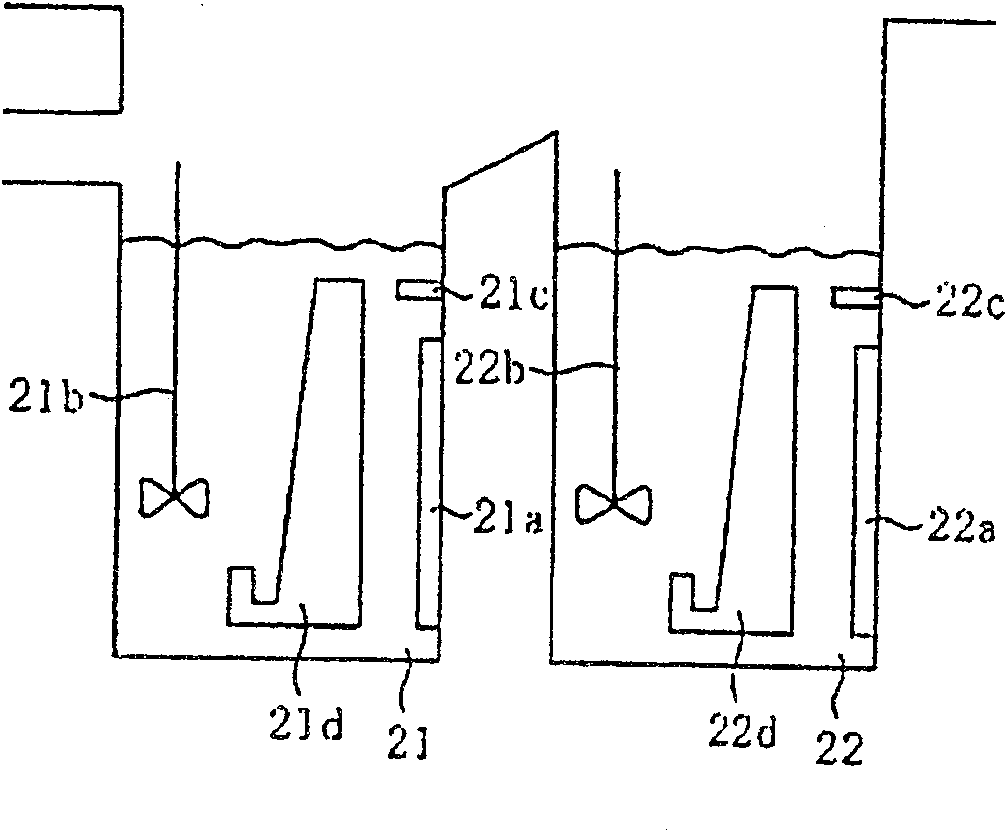

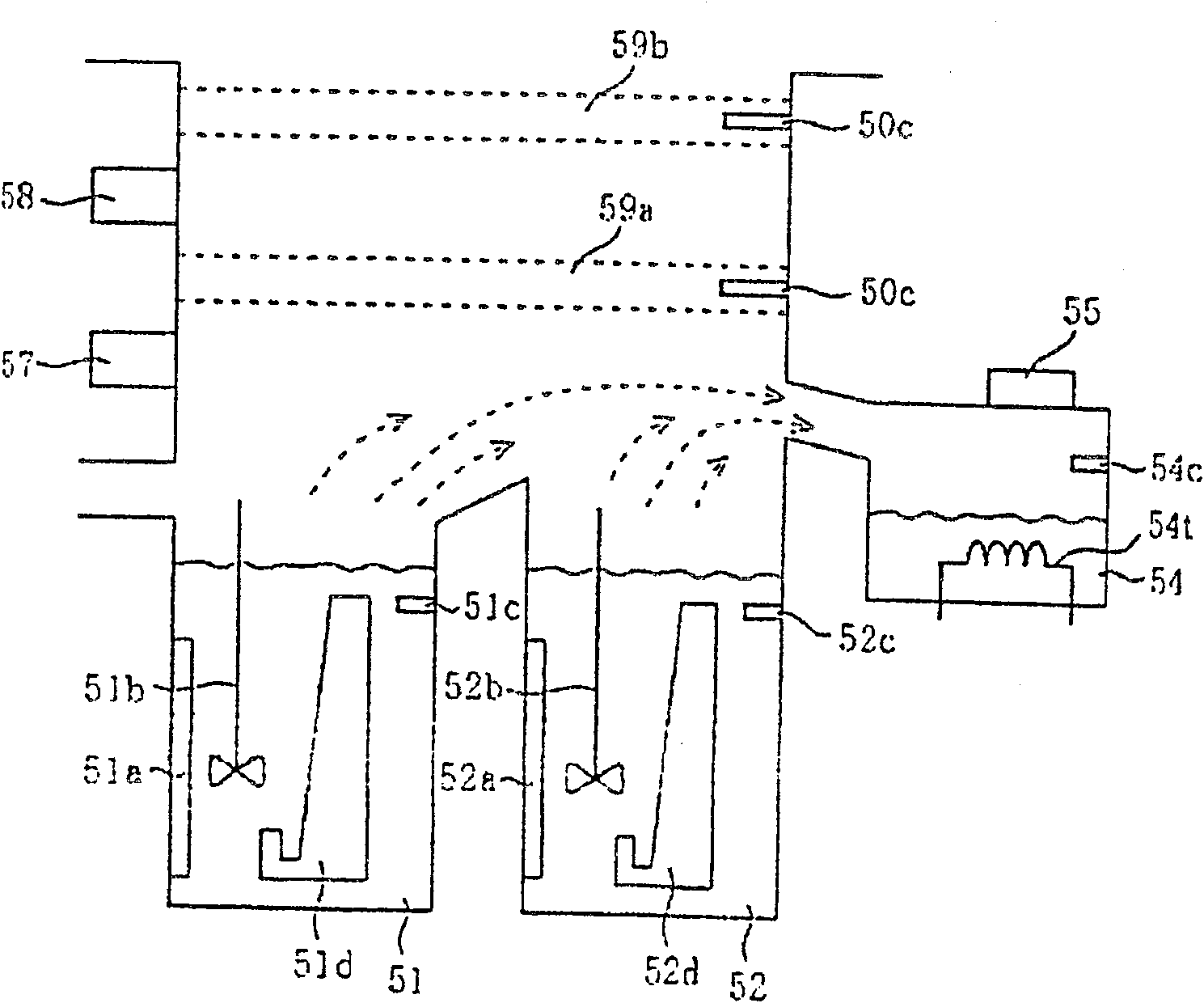

[0071] Next, a cleaning device according to an embodiment of the present invention will be described. The mask as the object to be cleaned is the same as in the Figure 15 to Figure 17 The same mask 10 used in the conventional evaporation step is shown. That is, the mask is composed of a metal thin film in which holes 11 of approximately several microns in length and width are formed along a predetermined pattern for forming an organic material. The metal thin film is made of, for example, nickel (Ni) and iron (Fe). In addition, a metal frame 12 made of nickel (Ni) and iron (Fe) is fixed to the edge of the mask. The metal frame 12 has a locking portion 13 . Hereinafter, the mask 10 fixed to the metal frame 12 is simply referred to as "mask 10".

[0072] The cleaning device of this embodiment is to remove the mask 10 attached to the metal thin film for vapor deposition in the vapor deposition step of vapor-depositing the organic material for organic EL on the insulating subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com