Colouring photosensitive resin composition

A technology of photosensitive resin and composition, applied in optics, optical components, opto-mechanical equipment, etc., can solve the problem of no structure of products

- Summary

- Abstract

- Description

- Claims

- Application Information

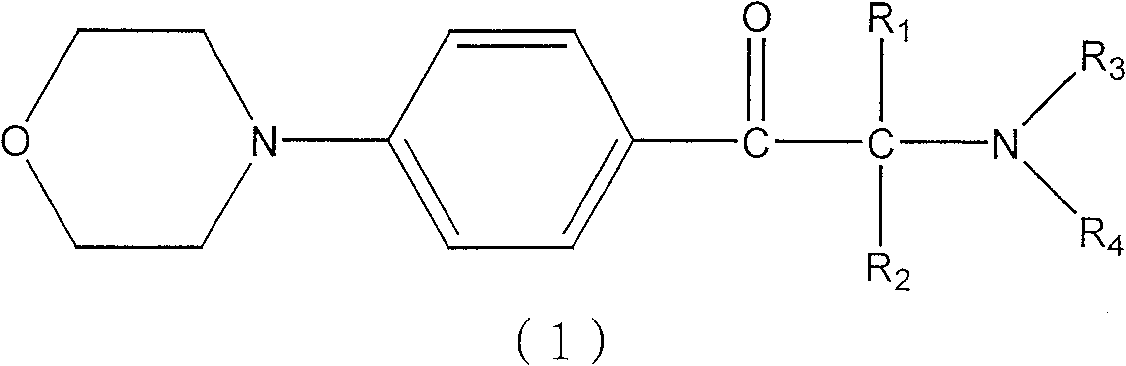

AI Technical Summary

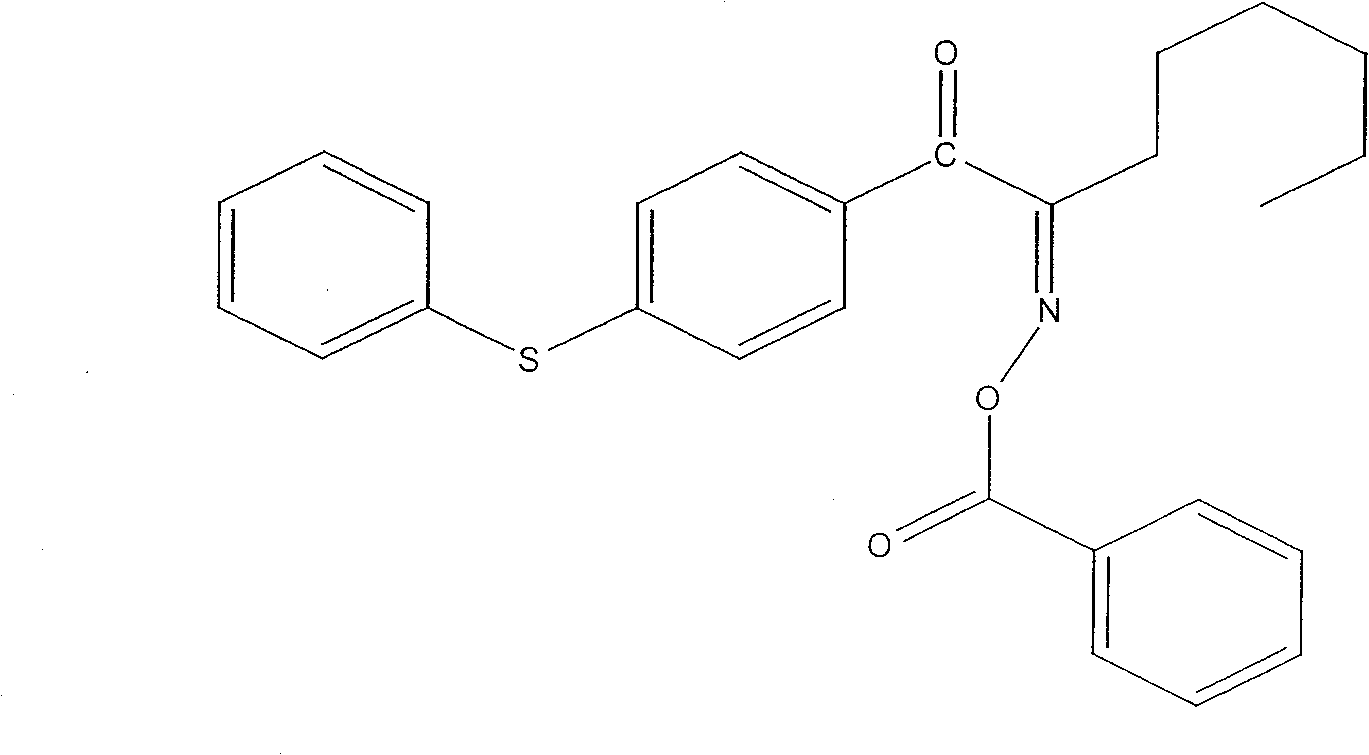

Problems solved by technology

Method used

Image

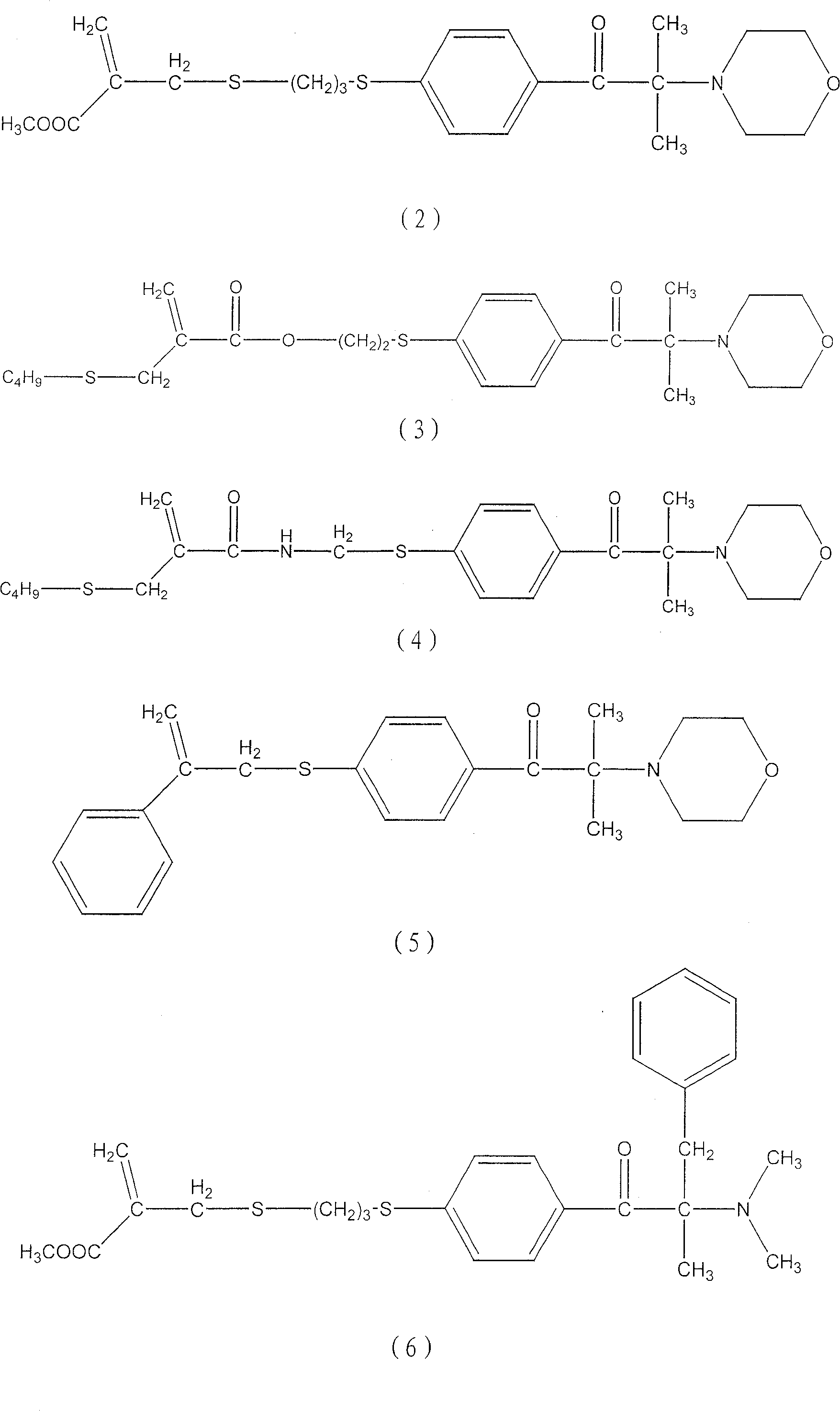

Examples

Embodiment 1

[0177] Among the components described in the following Table 1, the total amount of the pigment that is the precolor material (D) and the pigment dispersant that is the additive (F) becomes 20% by mass was mixed, and the pigment was sufficiently dispersed using a bead mill, then the beads were separated, and the remaining component including propylene glycol monomethyl ether acetate was added and mixed to obtain a colored photosensitive resin composition.

[0178] Table 1

[0179] Coloring material (D)

[0180] A 2-inch square glass substrate (manufactured by Corning, #1737) was washed sequentially with a neutral detergent, water, and alcohol, followed by drying. Make 100mJ / cm 2 The exposure amount (365nm) was exposed, and the film thickness after drying was 1.9 μm after omitting the thickness during the development process. The above-mentioned colored photosensitive resin composition was coated on the glass substrate, and then, in a clean oven, the 100°C for 3 min...

Embodiment 2

[0182] In Example 1, except having changed Irgacure-369 into the following oxime type initiator, the same operation as Example 1 was performed, and the evaluation result is shown in Table 2.

[0183]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com