Wool low-temperature dyeing method

A low-temperature dyeing and wool technology, applied in the field of low-temperature dyeing of wool, can solve the problems of complex process, unsatisfactory effect, high acidity, etc., and achieve the effect of high dyeing bath exhaustion rate, fast dyeing rate and low dyeing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

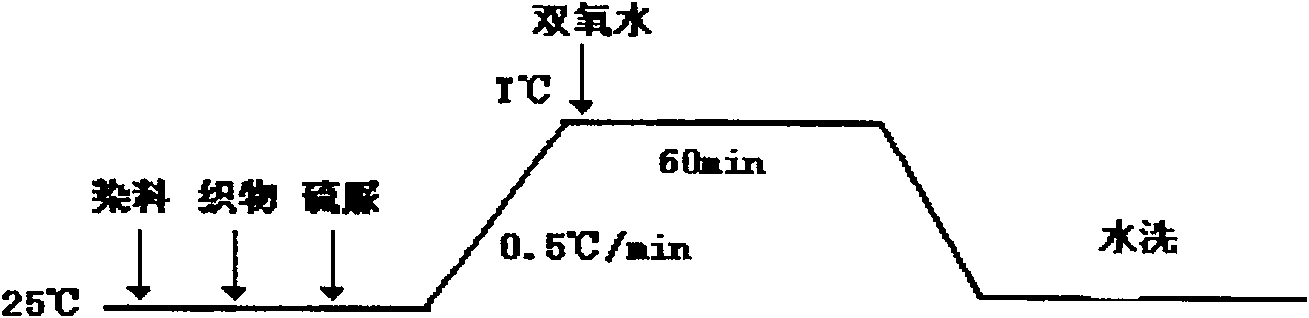

[0023] Example 1 Low temperature dyeing of wool skein with acid dye

[0024] Hang the worsted wool skein into the skein dyeing machine, add water to the specified liquor ratio, add 209 detergent and run for 5 minutes, then drain the water. Re-introduce water to the specified liquor ratio, add pre-dissolved weak acid magenta blue 6B dye, run for 10 minutes, add thiourea (according to the content of 0.05 moles in the dyeing bath), heat up after running for 10 minutes, and the temperature rise rate is controlled at 0.5°C per minute . After heating up to 80°C, add pre-diluted hydrogen peroxide (according to the content of 0.15 moles in the dyeing bath), keep it warm for 60 minutes, then cool down and wash it out of the vat. The color depth of the skein yarn obtained by this process is equivalent to the color depth at nearly 100°C without redox system.

[0025] Dye uptake rate (%) K / S

[0026] Routine dyeing at 98°C for 1.5h 88.9 35.27

[0027] Redox s...

Embodiment 2

[0028] Example 2 Low-temperature dyeing of wool garments with acid dyes

[0029] Put the woolen woolen sweater garment into the side paddle type garment dyeing machine, add water to the specified liquor ratio, add 209 detergent and run for 5 minutes, then drain the water. Re-introduce water to the specified bath ratio, add pre-dissolved weak acid yellow 6G dye, run for 10 minutes, add thiourea (according to the content of 0.01 mole in the dye bath), and run for 10 minutes to raise the temperature, and the temperature rise rate is controlled at 0.5°C per minute. After raising the temperature to 80°C, add pre-diluted hydrogen peroxide (according to the content of 0.03 moles in the dyeing bath), keep it warm for 60 minutes, then cool down and wash it out of the vat. The color depth of the woolen sweater obtained by this process is equivalent to the color depth near 100°C without redox system.

[0030] Dye uptake rate (%) K / S

[0031] Routine 98 dyeing ...

Embodiment 3

[0033] Embodiment 3 low temperature dyeing of wool skein reactive dye

[0034] Put the woolen woolen sweater garment into the side paddle type garment dyeing machine, add water to the specified liquor ratio, add 209 detergent and run for 5 minutes, then drain the water. Re-introduce water to the specified liquor ratio, add pre-dissolved Lanasol Yellow 4GK dye, run for 10 minutes, add thiourea (based on the content of 0.01 mole in the dye bath), and run for 10 minutes to raise the temperature. The temperature rise rate is controlled at 0.5°C per minute. After raising the temperature to 85°C, add pre-diluted hydrogen peroxide (according to the content of 0.03 moles in the dye bath), keep it warm for 60 minutes, then add ammonia water to adjust the pH of the dye bath to 8.5, and perform ammonia washing for 20 minutes, then cool down and wash out the vat. The color depth of the woolen sweater obtained by this process is equivalent to the color depth near 100°C without redox system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com