Wavelength divided duplexing equipment and packing method

A wavelength division multiplexer and packaging method technology, applied in wavelength division multiplexing systems, instruments, coupling of optical waveguides, etc., can solve the problem of affecting the transmission of optical signals, increase the manufacturing time of the packaging process, and increase the packaging time of the wavelength division multiplexer. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The aforementioned and other technical content, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

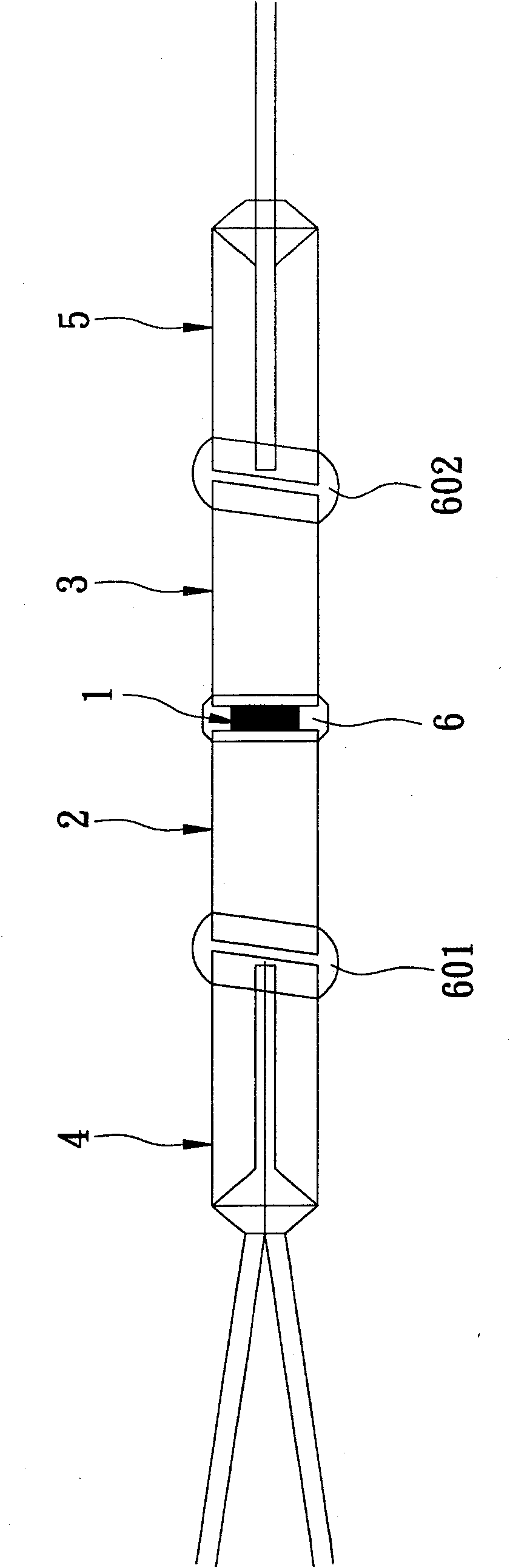

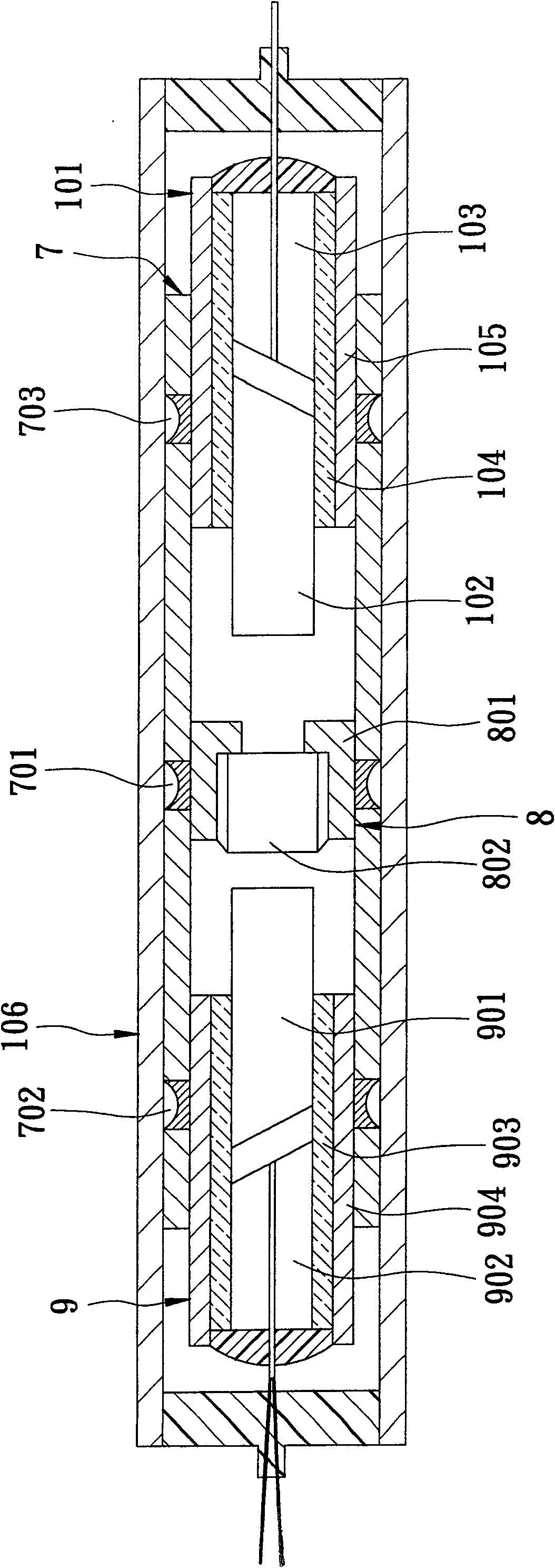

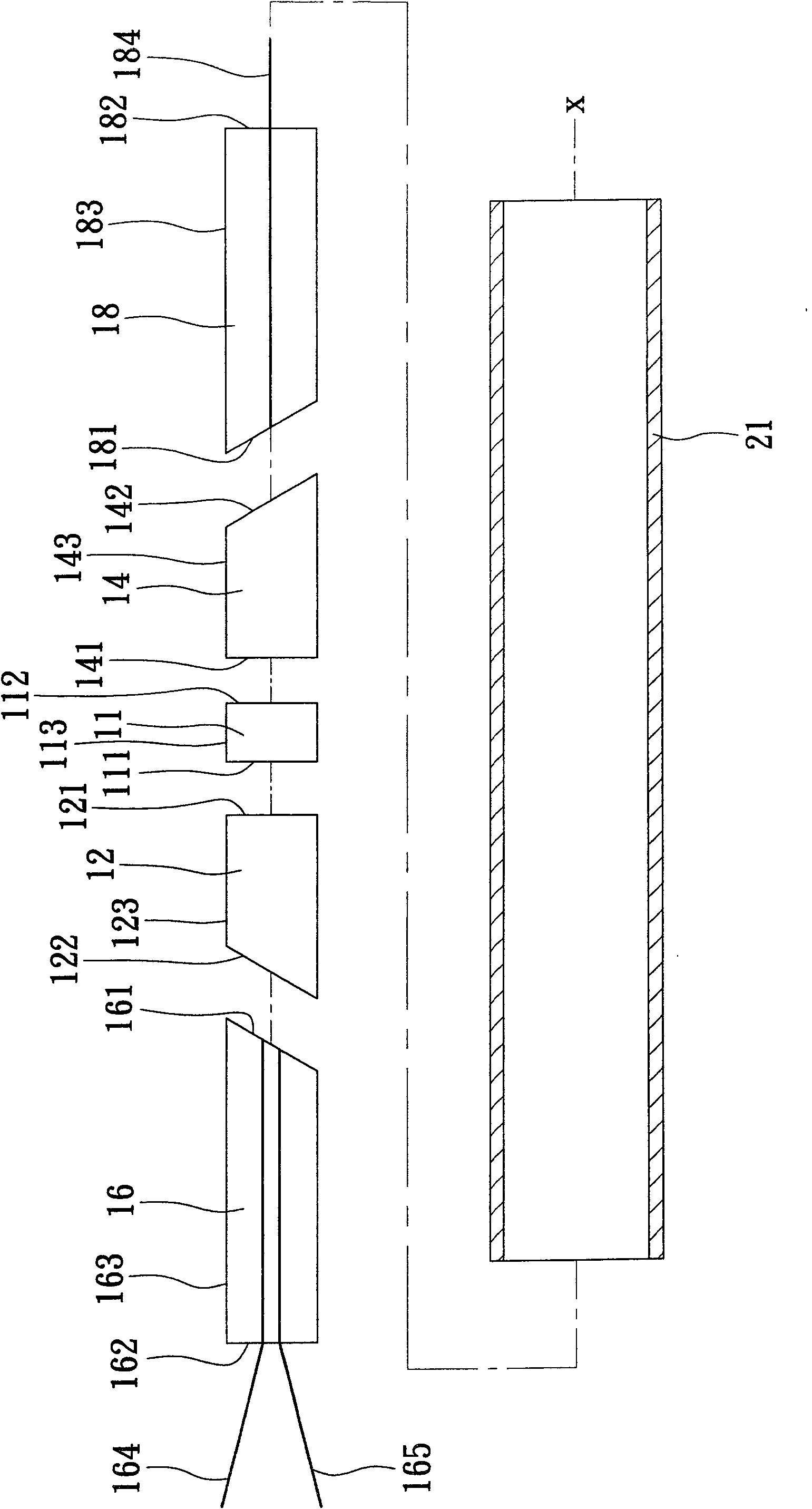

[0020] refer to Figure 13 , is the package structure of the wavelength multiplexer produced by the preferred embodiment of the packaging method of the wavelength multiplexer of the present invention, including a wavelength division unit 10 , an outer tube unit 20 , and a positioning adhesive layer 30 . The demultiplexing unit 10 includes a filter 11, a first graded index lens 12, a first UV glue layer 13, a second graded index lens 14, a second UV glue layer 15, a first optical fiber Conduit 16, a third UV adhesive layer 17, a second optical fiber conduit 18, a fourth UV adhesive layer 19, a first thermosetting adhesive layer 191, a second thermosetting adhesive layer 192, a third thermosetting adhesive layer 193, and a fourth thermosetting adhesive lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com