Welding agent for braze, braze method and printing substrate

A brazing method and flux technology, which is applied in the field of flux, brazing method and printed substrate, can solve the problems of solder joint strength insulation resistance reduction, brazing and printed substrate reliability damage, short circuit, etc., to achieve good brazing performance, Improves stability, prevents drastic reduction in effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

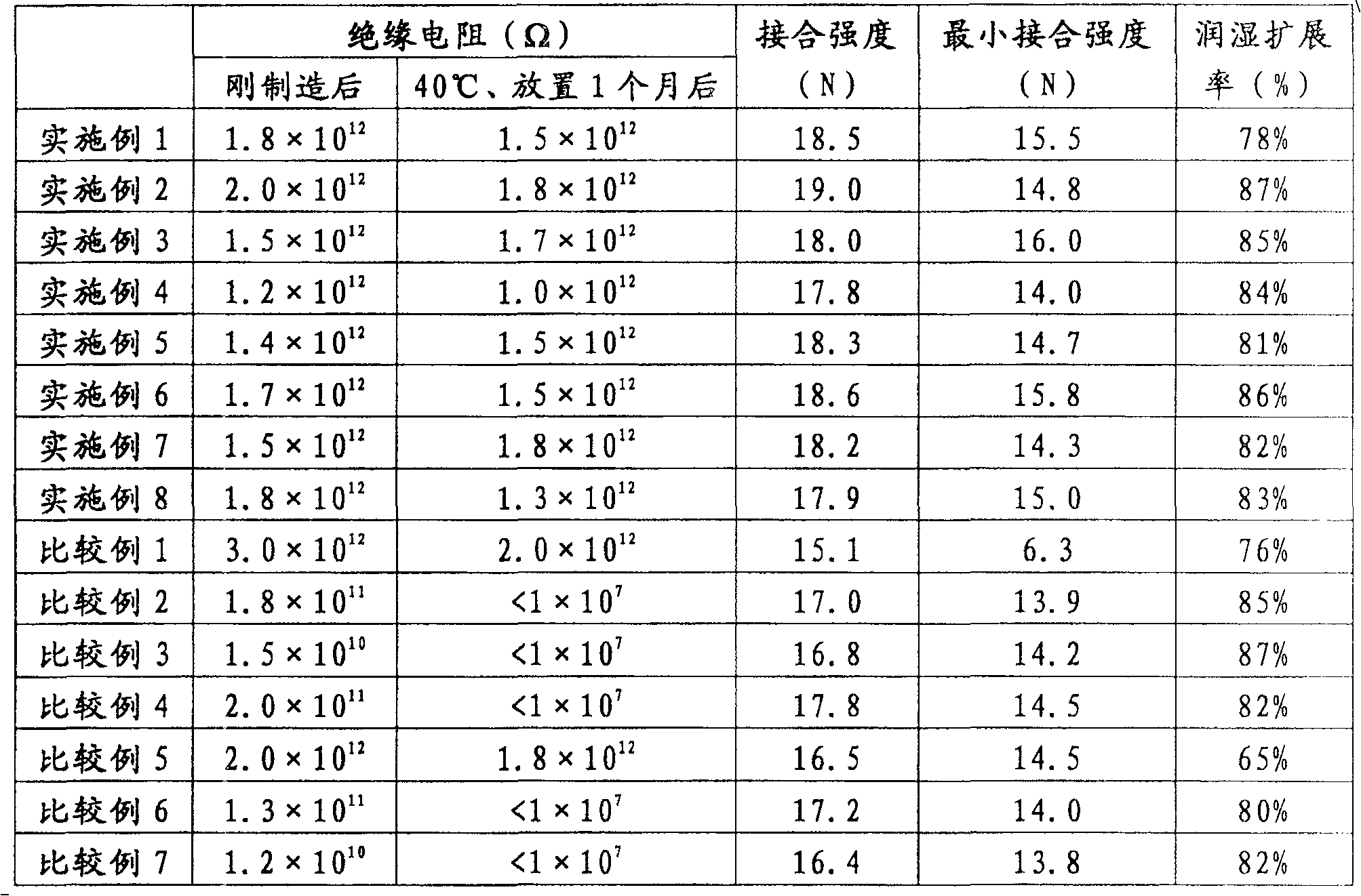

experiment example 1~8 and comparative example 1~7

[0046] [Choice of Copper Salt and Active Agent]

[0047] As the metal salt, the following are selected.

[0048] A:(C 17 h 35 COO) 2 Cu

[0049] B:(C 7 h 15 COO) 2 Cu

[0050] C:(C 21 h 43 COO) 2 Cu

[0051] D:(C 17 h 35 COO) 2 Pb

[0052] As the active agent, the following substances were selected.

[0053] E: C 7 h 15 COOH

[0054] F: C 17 h 35 COOH

[0055] G: C 21 h 43 COOH

[0056] H:(CH 3 ) 2 CHNH 2 ·HCl

[0057] Here, the order of acidity is H>E>F>G.

[0058] [Preparation of Rosin Flux]

[0059] WW grade Toichiru rosin 70 parts by weight

[0060] 25 parts by weight of hexyl carbitol

[0061] 5 parts by weight of hydrogenated castor oil

[0062] Mix the materials according to the above formula, heat to 120°C to melt, cool to room temperature, and prepare viscous flux.

[0063] [Preparation of acrylic flux]

[0064] Acrylic resin (Pararoid B-48N manufactured by Romde Haus Co., Ltd.) 50 parts by weight of hexyl carbitol 45 parts by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com