Water washing continuous boiling method and its device for grass fiber raw material

A grass fiber and raw material technology, which is applied in the field of water washing and continuous cooking of grass fiber raw materials and its device, can solve the problems of waste liquid recovery, complex structure, poor quality, etc., and achieve stable operation, reliable feeding, and reasonable settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

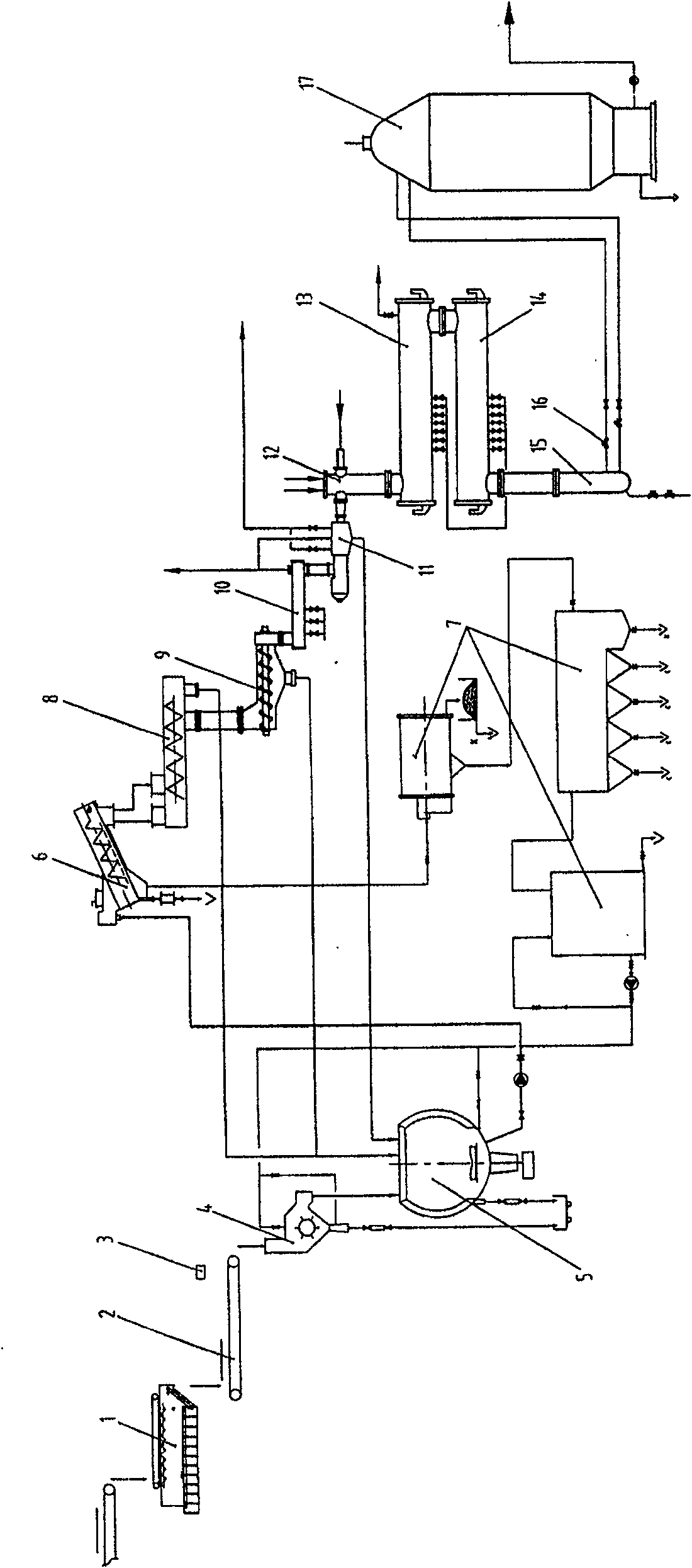

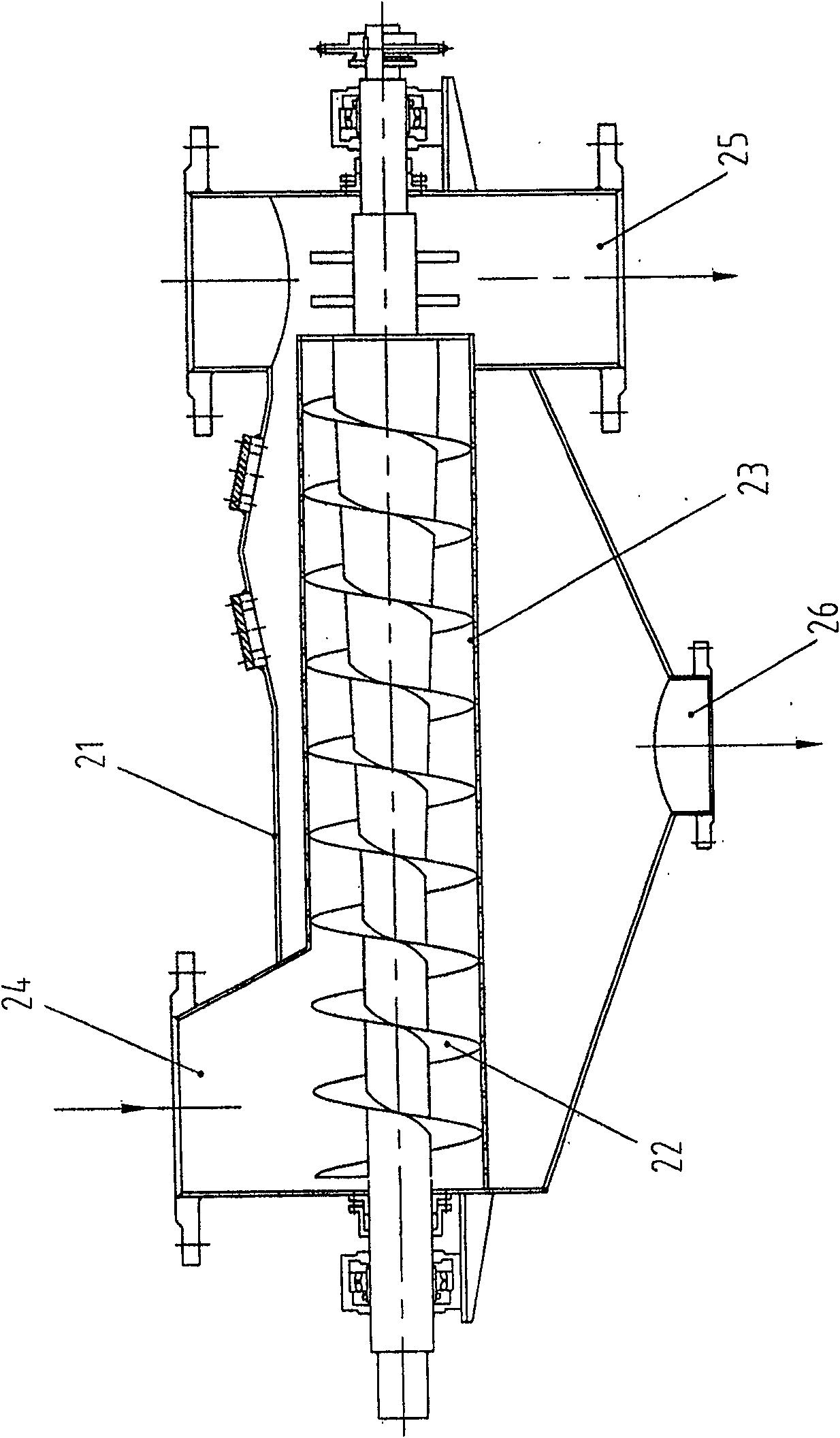

[0051]As mentioned above, because straw, wheat straw, kenaf, bagasse and other grass fiber raw materials have the characteristics of high ash and miscellaneous cell content, poor water drainage, soft quality, high water retention and low internal friction coefficient, the grass after washing If the flakes are not dehydrated, it is difficult to feed the horizontal tube continuous digester, that is, problems such as back spray and slippage are prone to occur, so normal cooking cannot be performed. Therefore, the feature of the continuous cooking method for grass fiber raw material washing provided by the invention is that in the continuous cooking process, a metering extrusion dehydrator with a filter screen can be effectively removed to keep constant and high. Raw material dryness and capacity, so that the continuous cooking of grass flakes can be carried out more stably. Such as figure 1 As shown, in the water-washing continuous cooking process of grass fiber raw materials pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap