Red organic electroluminescent devices and its preparation method

An electroluminescence and red technology, applied in the field of red organic electroluminescence devices and their preparation, can solve the problems of incomplete energy transfer of trivalent europium complexes, unfavorable device luminous efficiency and brightness, only 1.4%, etc. luminescence efficiency, increase the probability of carrier recombination, and reduce the effect of exciton concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

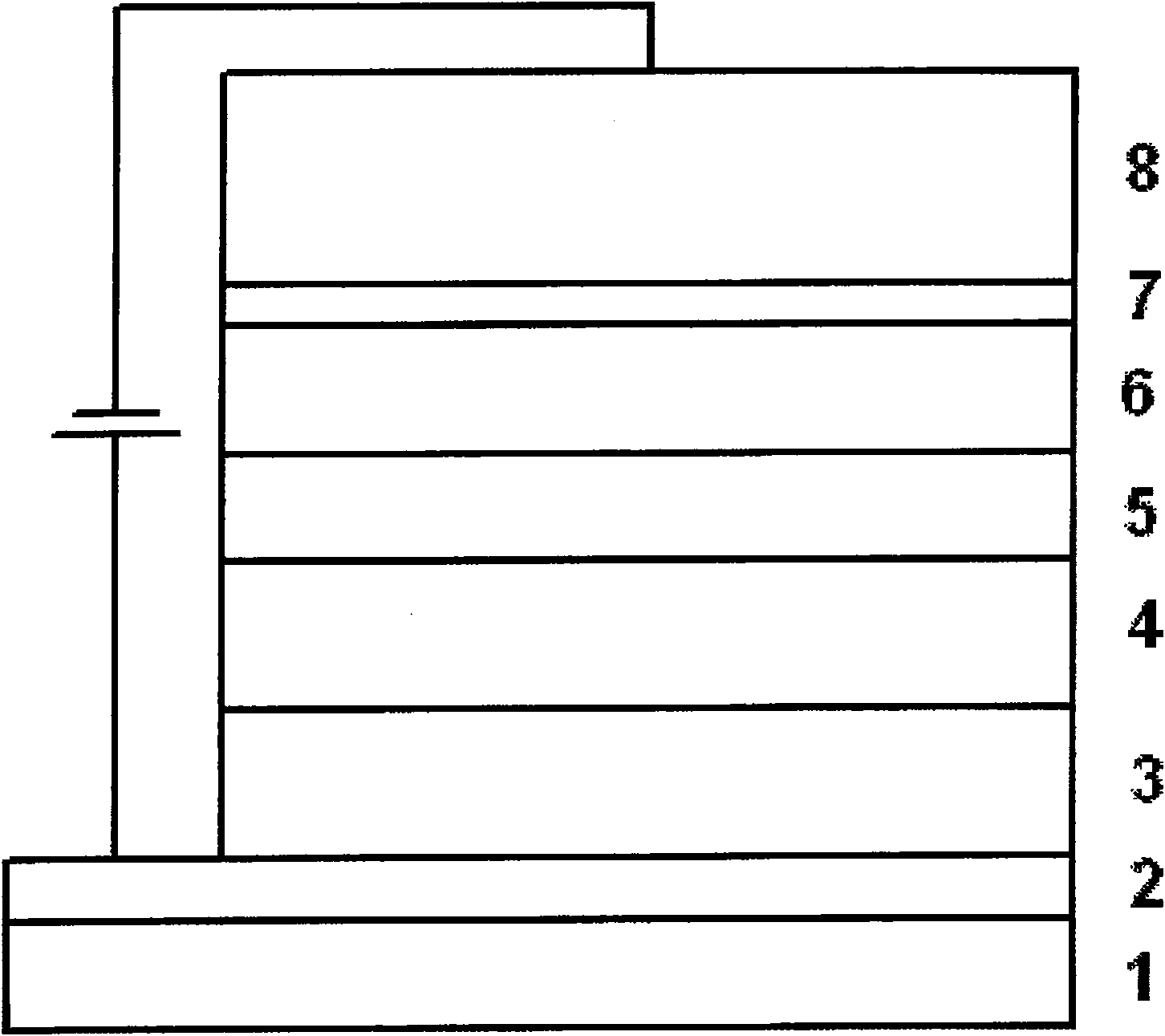

[0040] Firstly, the ITO anode layer on the ITO glass is chemically etched into strip electrodes with a width of 10 mm and a length of 30 mm, and then ultrasonically cleaned with cleaning solution and deionized water for 15 minutes and dried in an oven. Then put the dried substrate into the pretreatment vacuum chamber, and then transfer the ITO anode to the organic evaporation chamber after 10 minutes of low-pressure oxygen plasma treatment with a voltage of 250 volts under an atmosphere with a vacuum degree of 10 Pa. In a vacuum of 1-5 x 10 -5 In Pa's organic evaporation chamber, a 50-nanometer-thick TPD hole-transport layer, a 45-nanometer-thick Eu(TTA) 3 The phen and AlQ were co-incorporated into the emitting layer of CBP, a 20-nm-thick BCP hole-blocking layer, and a 30-nm-thick AlQ electron-transporting layer. Next, the unfinished devices are transferred to a metal evaporation chamber at 5-8 x 10 -5 A 1.0nm thick LiF buffer layer was evaporated sequentially under a vacuum...

Embodiment 2

[0042] Firstly, the ITO anode layer on the ITO glass is chemically etched into strip electrodes with a width of 10 mm and a length of 30 mm, and then ultrasonically cleaned with cleaning solution and deionized water for 15 minutes and dried in an oven. Then put the dried substrate into the pretreatment vacuum chamber, and then transfer the ITO anode to the organic evaporation chamber after 10 minutes of low-pressure oxygen plasma treatment with a voltage of 250 volts under an atmosphere with a vacuum degree of 10 Pa. In a vacuum of 1-5 x 10 -5 In Pa's organic evaporation chamber, a 50-nanometer-thick TPD hole-transport layer, a 45-nanometer-thick Eu(TTA) 3 The phen and AlQ were co-incorporated into the emitting layer of CBP, a 20-nm-thick BCP hole-blocking layer, and a 30-nm-thick AlQ electron-transporting layer. Next, the unfinished devices are transferred to a metal evaporation chamber at 5-8 x 10 -5 A 1.0nm thick LiF buffer layer was sequentially evaporated in a Pascal va...

Embodiment 3

[0044] Firstly, the ITO anode layer on the ITO glass is chemically etched into strip electrodes with a width of 10 mm and a length of 30 mm, and then ultrasonically cleaned with cleaning solution and deionized water for 15 minutes and dried in an oven. Then put the dried substrate into the pretreatment vacuum chamber, and then transfer the ITO anode to the organic evaporation chamber after 10 minutes of low-pressure oxygen plasma treatment with a voltage of 250 volts under an atmosphere with a vacuum degree of 10 Pa. In a vacuum of 1-5 x 10 -5 In Pa's organic evaporation chamber, a 50-nanometer-thick TPD hole-transport layer, a 45-nanometer-thick Eu(TTA) 3 The phen and AlQ were co-incorporated into the emitting layer of CBP, a 20-nm-thick BCP hole-blocking layer, and a 30-nm-thick AlQ electron-transporting layer. Next, the unfinished devices are transferred to a metal evaporation chamber at 5-8 x 10 -5 A 1.0 nm-thick LiF buffer layer was evaporated sequentially under a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com