Method for preparing composite chlorine dioxide

A production method, chlorine dioxide technology, applied in the direction of chlorine dioxide, electrolysis process, electrolysis components, etc., can solve the problems of low purity of chlorine dioxide, waste of raw materials, secondary pollution, etc., to facilitate large-scale production, inhibit reproduction and regeneration , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

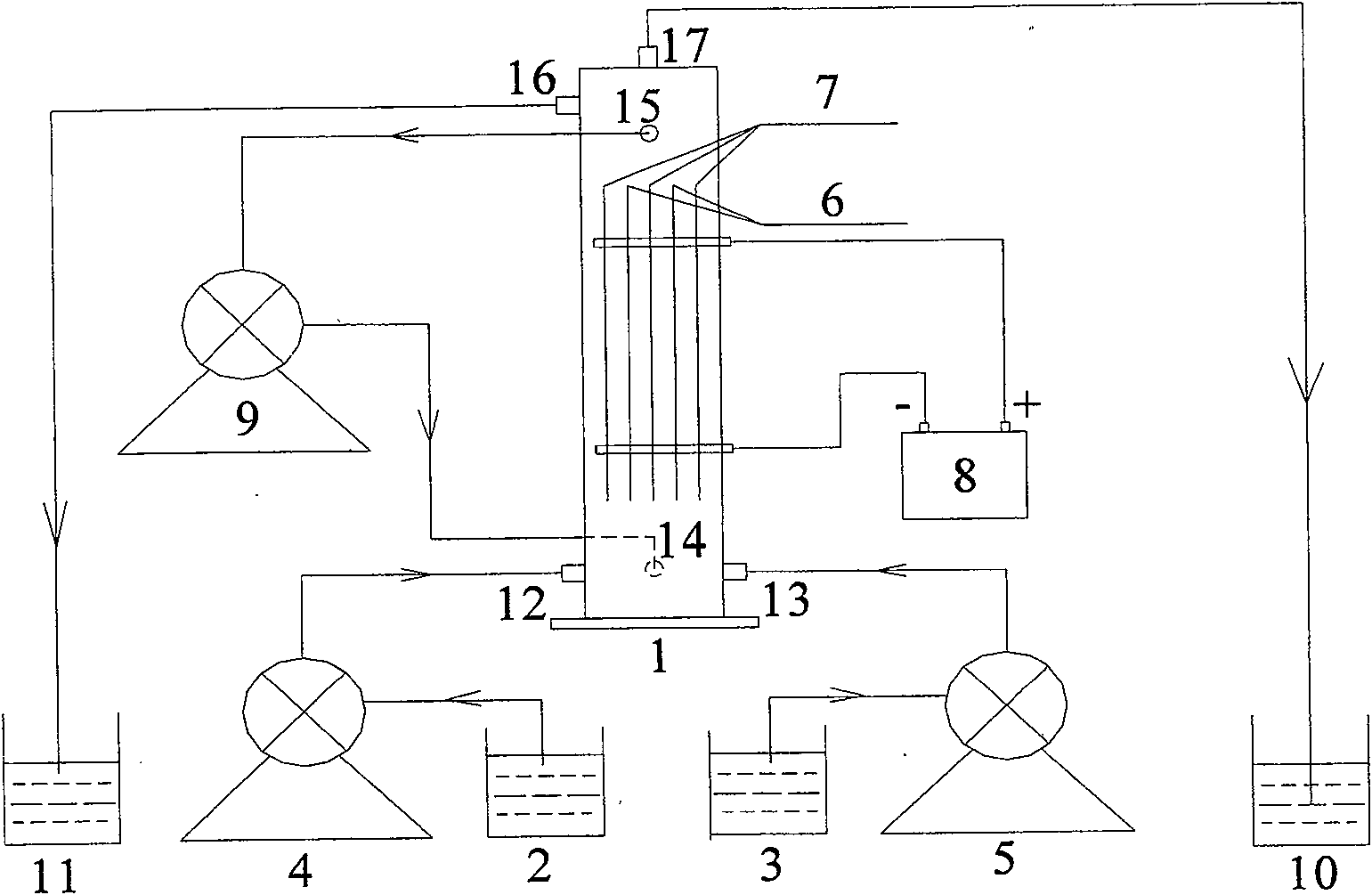

[0033] Embodiment 1: The composite chlorine dioxide production device that adopts is provided with non-diaphragm flat plate electrode reactor 1, raw material liquid tank, metering pump, absorption liquid tank 10, product liquid tank 11 and power supply 8; No diaphragm flat plate electrode reactor 1 bottom It is equipped with a first feed port 12, a second feed port 13, an internal circulation inlet 14, a gas outlet 17 on the top, a liquid outlet 16 and an internal circulation outlet 15 on the upper side, and a built-in stainless steel as a cathode for chlorine analysis. The plate electrode is used as an anode, and 4 cathodes and 4 anodes are arranged at intervals to form a cathode group 6 and an anode group 7; the first raw material liquid tank 2 is connected to the plate electrode reactor 1 without a diaphragm by the first metering pump 4; the second raw material liquid tank 3. Connect the second metering pump 5 to the plate electrode reactor 1 without diaphragm; the two ends ...

Embodiment 2

[0041] Embodiment 2: The composite chlorine dioxide production device that adopts is provided with no diaphragm plate electrode reactor 1, raw material liquid tank, metering pump, absorption liquid tank 10, product liquid tank 11. and power supply 8; No diaphragm plate electrode reactor 1 The lower part is provided with the first feed port 12, the second feed port 13, the internal circulation inlet 14, the top is provided with the gas outlet 17, the upper part is provided with the liquid outlet 16 and the internal circulation outlet 15, and the built-in titanium electrode is used as the cathode. The chlorine-analyzing plate electrode is used as the anode, and 6 cathodes and 6 anodes are arranged at intervals to form the cathode group 6 and the anode group 7; the first raw material liquid tank 2 is connected to the non-diaphragm flat plate electrode reactor 1 by the first metering pump 4; the second raw material The liquid tank 3 is connected to the plate electrode reactor 1 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com