Method for beating pulp

A pulp and process technology, applied in pulp beating methods and other directions, can solve problems such as inability to obtain effects, narrow scope of action, hindering the bonding between fibers, etc., so as to reduce operating failures and product defects, improve separation efficiency, and reduce microbial damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

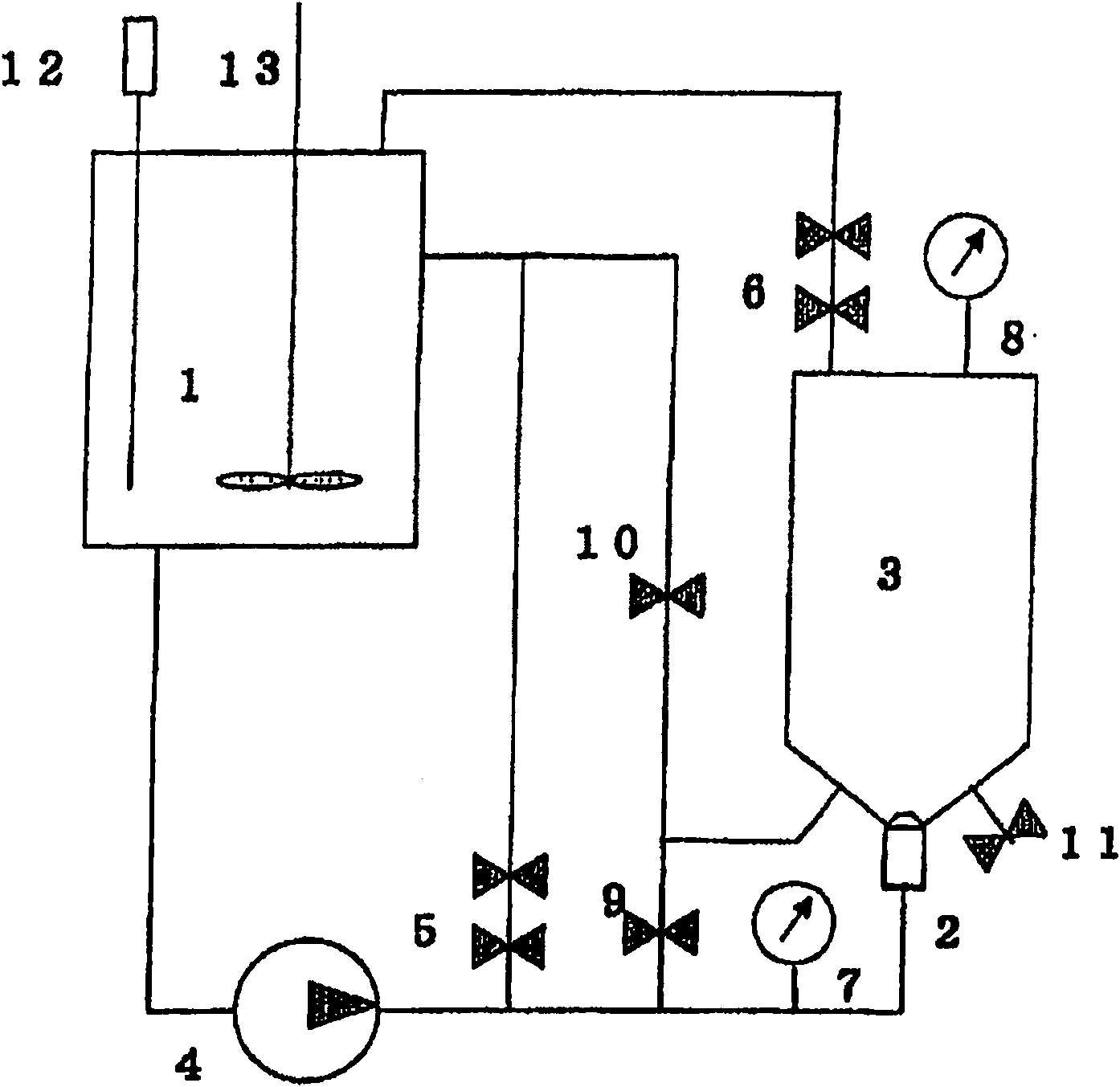

[0127] The commercially available hardwood bleached kraft pulp sheet was decomposed and softened with a low-concentration pulper as raw material A (freeness CSF666ml). After adjusting raw material A to any concentration, use such as figure 1 For the cavitation jet cleaning device shown (the nozzle diameter is 1.5mm), the pressure of the spray liquid (upstream side pressure) is 7MPa (jet flow speed 70m / s), and the pressure inside the sprayed container (downstream side pressure) It is 0.3MPa, and the treatment time is changed to adjust the drainage degree. In addition, a pulp suspension having a concentration of 1.1% by weight was used as the spray liquid, and the pulp suspension (1.1% by weight of concentration) in the container was subjected to cavitation treatment. For the treated pulp, water retention, screening test, and Canadian Standard Freeness (CSF) were measured, and the results are shown in Table 1.

[0128] Water retention: According to J.TAPPI No.26

[0129] Scre...

Embodiment 5~8

[0153] Using the thermomechanical pulp (freeness CSF 288ml) of the radia-tapine after scouring with the actual machine in the factory as raw material B, use the same cavitation jet cleaning device as in Example 1 to get the jet liquid pressure (upstream side pressure) ) is 7MPa (jet velocity 70m / second), the pressure inside the container being sprayed (downstream side pressure) is 0.3MPa, and the treatment time is changed to process and adjust the degree of drainage. The water retention, screening test, and Canadian standard freeness of the obtained pulp were measured, and the results are shown in Table 4. The handmade thin slices were made in the same manner as in Example 1, and the same items were measured. The results are shown in Tables 5 and 6.

Embodiment 9~11

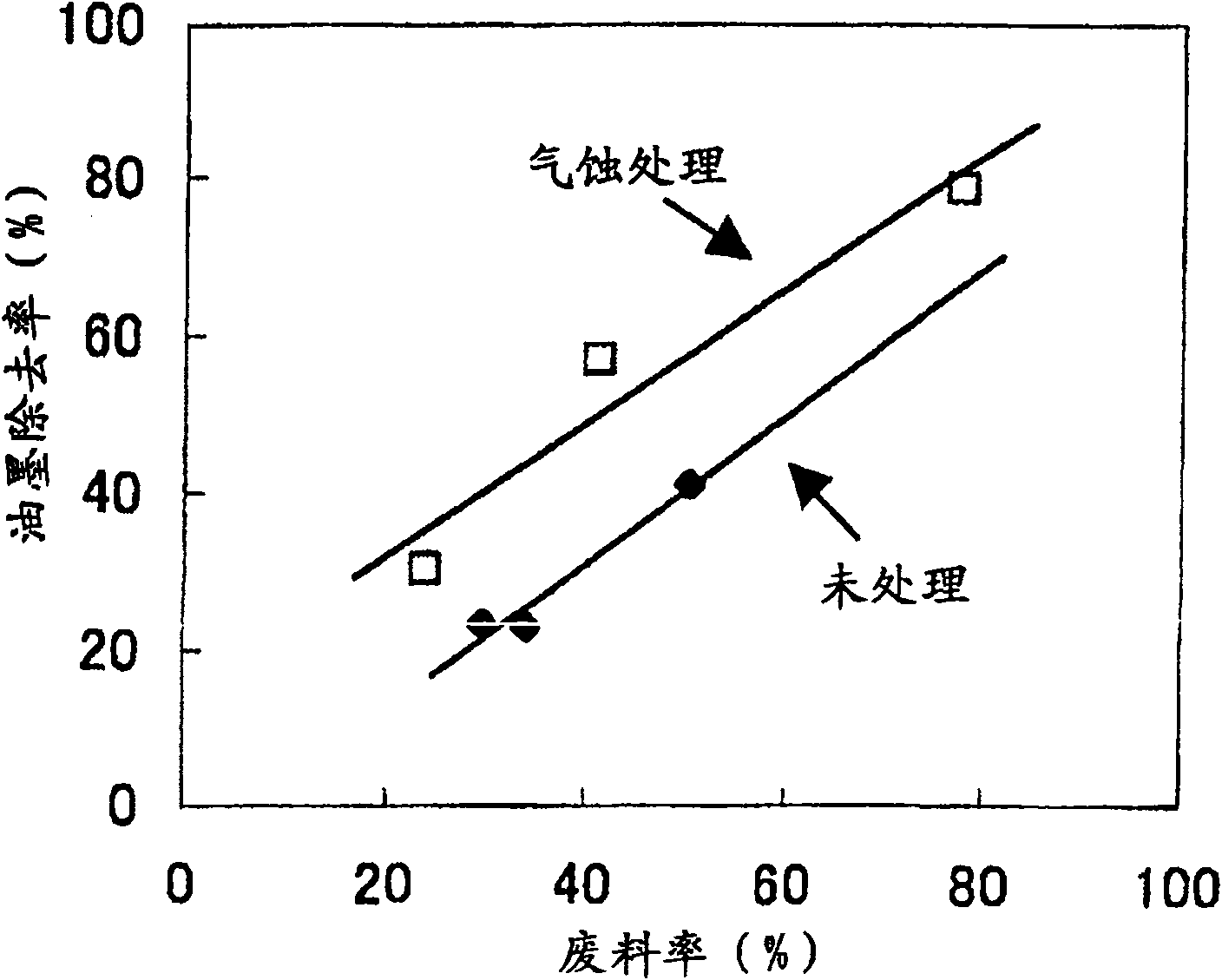

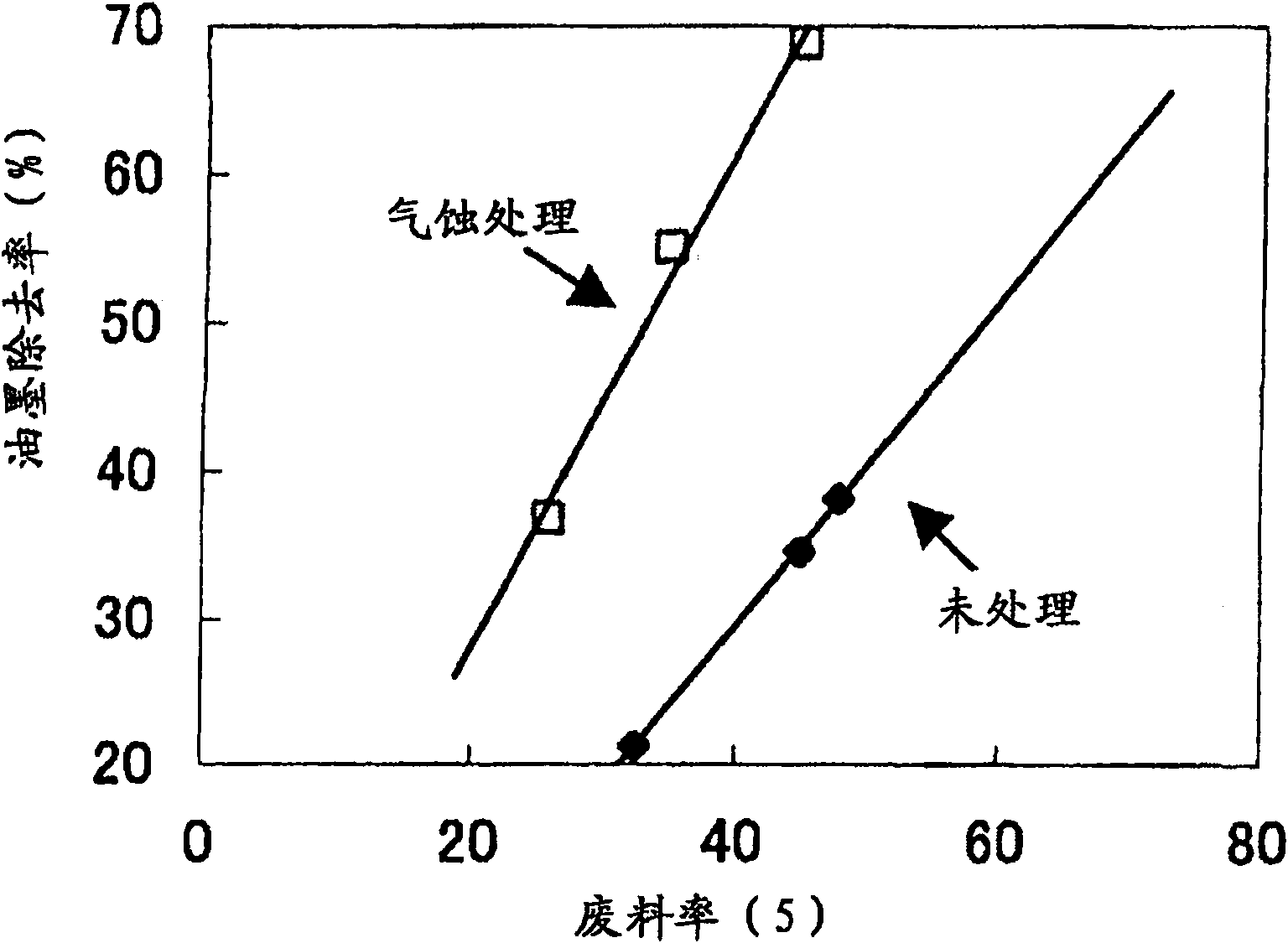

[0169] Old newspapers, old advertisements, old colored magazines and printed magazines are old paper blended in a weight ratio of 40 / 30 / 15 / 15, sodium hydroxide is added to it so that the relative pulp is 1.0% by weight, water After adjusting the pulp concentration to 15% by weight, it was fluffed at 40° C. for 6 minutes with a pulper as raw material C. After the raw material C is adjusted to any concentration, use the same cavitation jet flow cleaning device as in Example 1, get the spray liquid pressure (upstream side pressure) to be 7MPa (jet flow velocity 70m / second), and the water in the sprayed container The pressure (pressure on the downstream side) was 0.3 MPa, and the treatment time was changed to adjust the degree of drainage. The obtained image was measured for Canadian Standard Freeness, and the treated pulp was thoroughly washed on a 150-mesh screen. The pulp after cleaning was made into a hand-made sheet in the same manner as in Example 1, and the same items were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com