Titanic oxide nano pipe/high-efficiency glass fiber filter in situ synthesis supporting method

A technology of in-situ synthesis of titanium dioxide, applied in chemical instruments and methods, synthetic fibers, separation methods, etc., to achieve the effects of low price, good photocatalytic effect, and low production cost

Inactive Publication Date: 2010-02-10

SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a loading method for in-situ synthesis of titanium dioxide nanotubes / high-efficiency glass fiber filter paper, which solves the problems in the previous loading technology, realizes self-cleaning and sterilization of glass fiber filter paper, and prolongs the service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

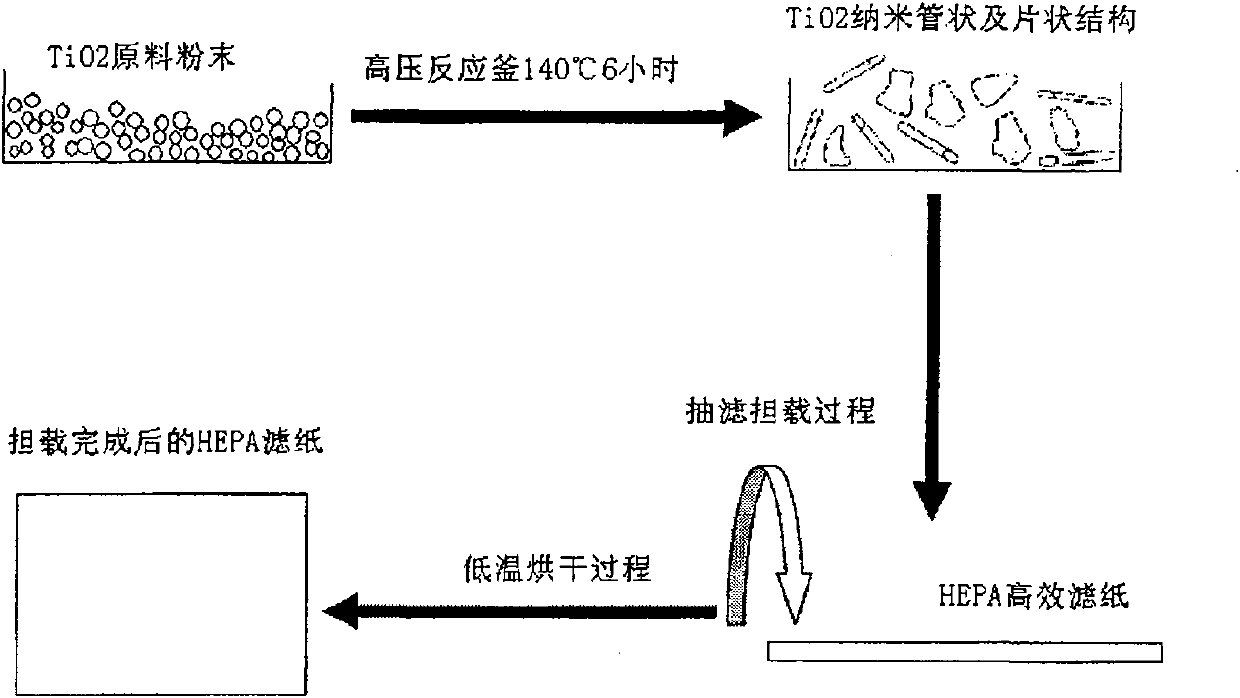

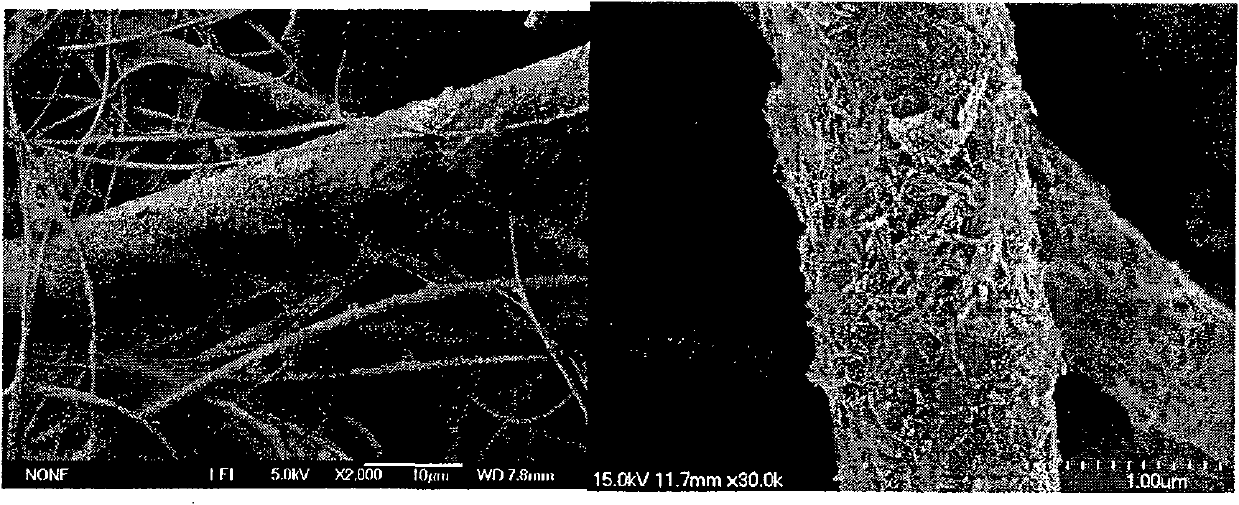

The invention discloses a support method of the in situ synthesis of titanic oxide nanotube / highly efficient glass fiber filter paper, which is characterized in that the method comprises the following steps that: (1) TiO2 powder is added into an NaOH solution and the mixed solution is transferred to a reaction kettle; (2) precipitate is obtained after hydrothermal reaction at a constant temperature of 110DEG C- 160DEG C for 6h-72h; (3) the precipitate obtained in step (2) is mixed with ethanol to form stable suspension after ultrasonic dispersion treatment for 15min, repeatedly filtered and washed by HEPA filter paper and deionized water until filter liquor is neutral; (4) the HEPA filter paper obtained from the step (3) is dried at 60DEG C. The method realizes the automatic cleaning andbactericidal function of the glass fiber filter paper, prolongs the service life of the filter paper, has simple technique and low requirements for materials and is suitable for industrial production.

Description

technical field The invention relates to a method for preparing filter paper for air filtration and purification, in particular to an in-situ synthesis and immobilization method of a one-dimensional nanotube structure photocatalytic material on a high-efficiency air filtration substrate. Background technique With the continuous development of social industrial production, the current environmental quality is deteriorating, and air pollution is becoming more and more serious. Due to the continuous increase of airborne pollutants such as harmful dust, smoke and other pollutants, it is very easy to cause people to suffer from respiratory tract infections, allergies, and asthma. Outbreaks and other diseases with symptoms directly related to air pollution, so people pay more attention to improving ambient air conditions. HEPA—glass fiber air filter paper is a high-efficiency filter material, mainly used as air and liquid purification filter paper. For example, it can remove har...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D39/14D06M11/46D06M101/16

Inventor 陈韦程小荣芦露华代凯

Owner SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com