Method for preparing plating aid for preventing omission of heat dip galvanization

A technology of hot-dip galvanizing and fluxing agent, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc. It can solve the problems of unsatisfactory effect, reduce iron ions in fluxing agent, etc., and reduce the amount of reclaimed water treatment , reduce smoke, reduce the effect of generating volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

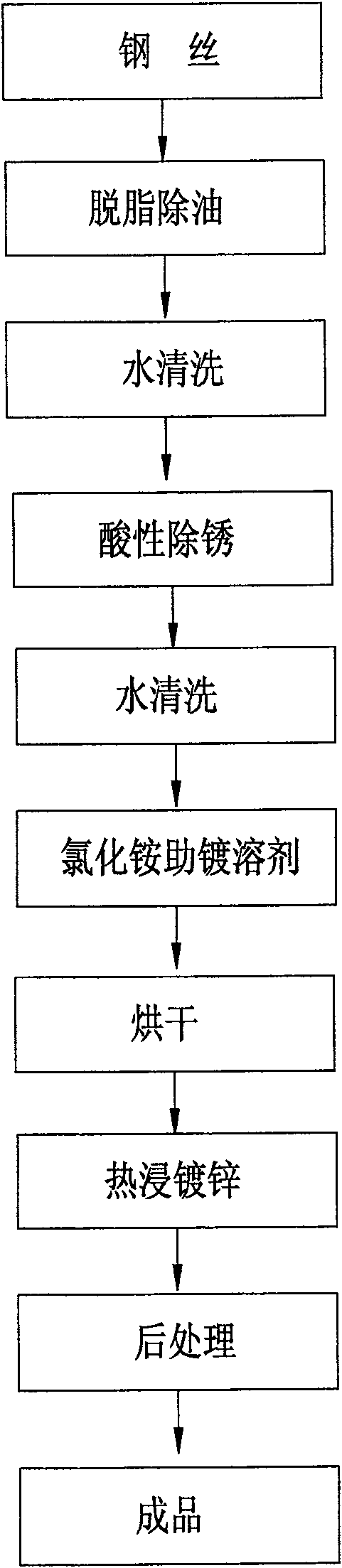

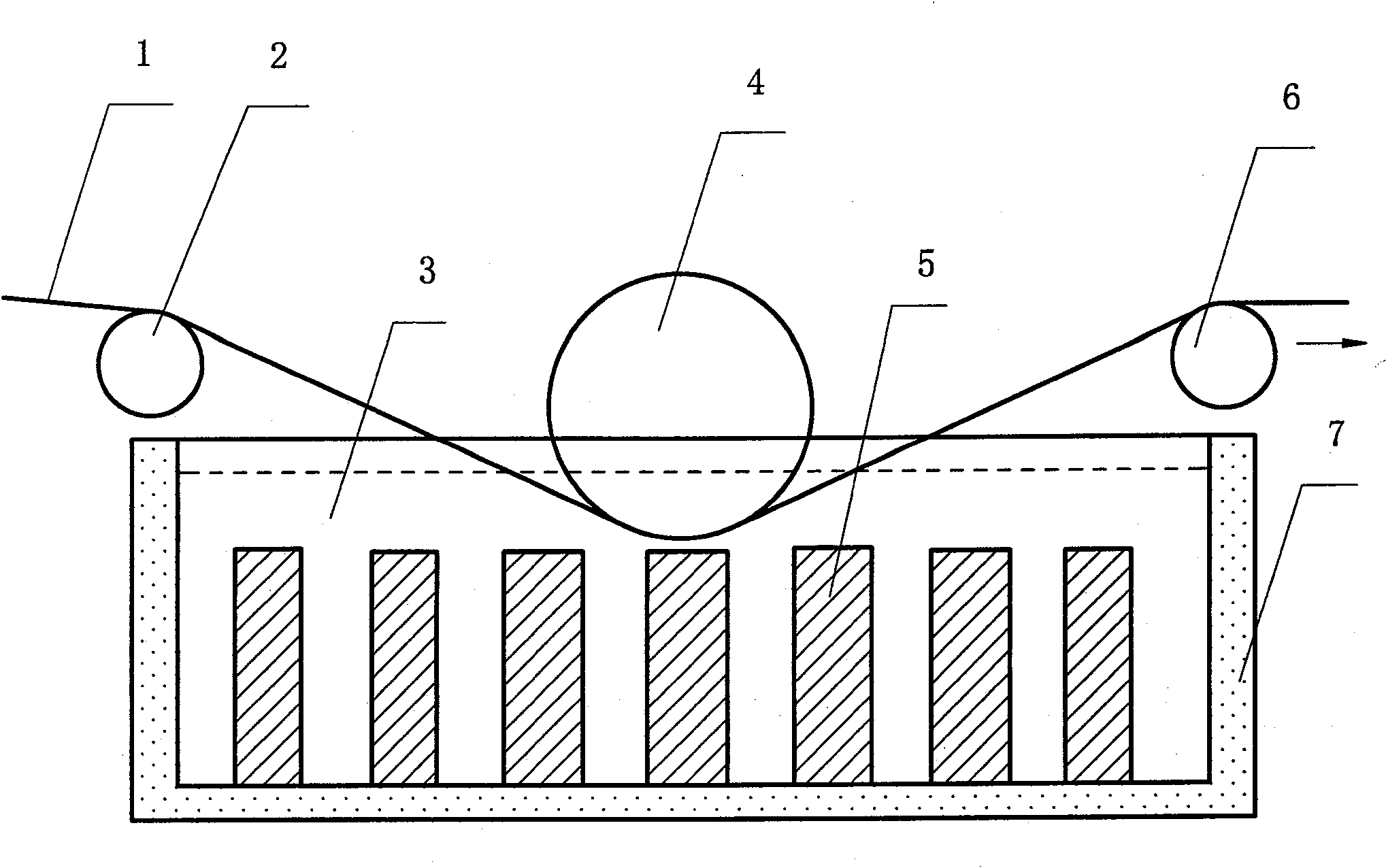

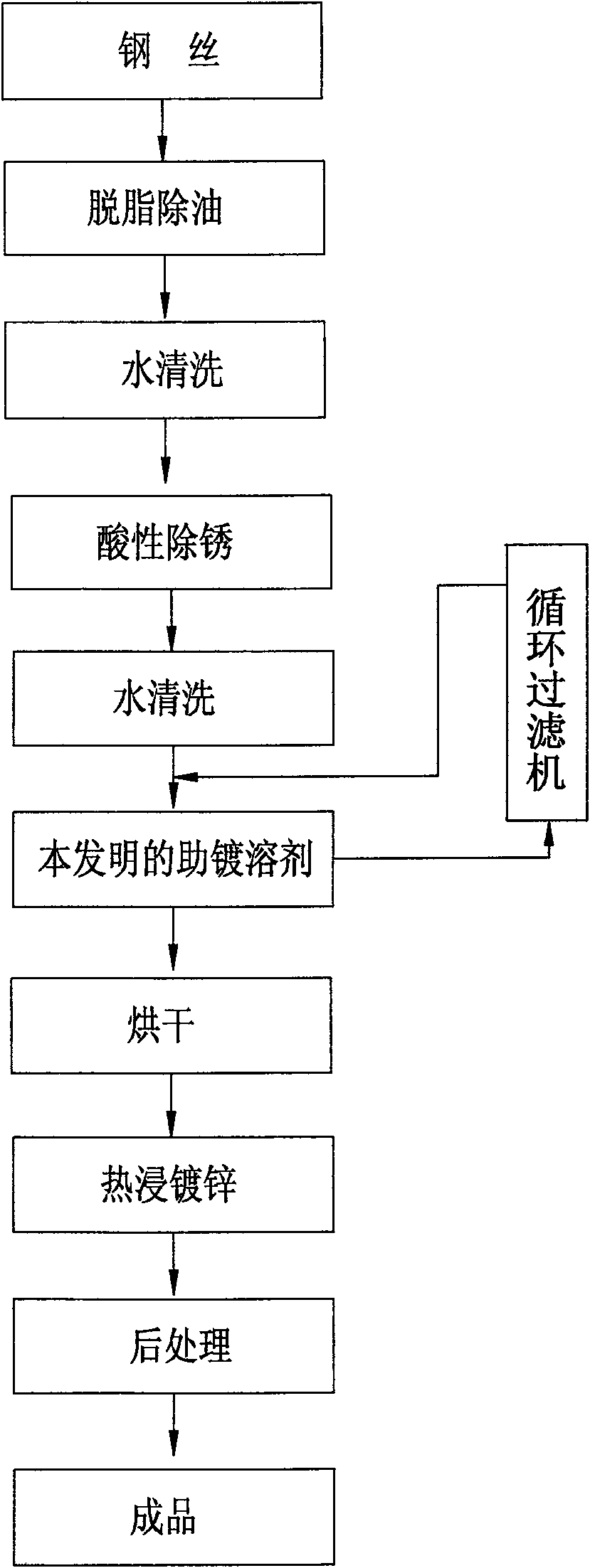

[0032] Embodiment one, see figure 2 , image 3 , using the existing steel wire hot-dip galvanizing method to remove rust on the surface of the steel wire with hydrochloric acid, using the characteristics of the fast wire routing speed and bringing hydrochloric acid and iron salt into the fluxing solvent with the surface of the steel wire, using the zinc slag (FeZn 13 ) from the zinc pot, put it into a mold and cool it into a square shape with a size of approximately: length 400×width 300×height 100 (mm), and directly place the cooled and formed zinc dross block vertically along the periphery of the flux bath. Using hydrochloric acid and zinc slag (FeZn 13 The chemical principle of the reaction of metal zinc in ) to form zinc chloride, the contact reaction area between the zinc slag block and the solution is large, and the zinc chloride in the fluxing solvent is produced all the time, and it is kept within a certain range, which meets the requirements of hot-dip galvanizing for...

Embodiment 2

[0039] Embodiment two, with the similarity of embodiment one no longer restate, difference is:

[0040] The components of the plating flux solvent include ammonium chloride 35-40g / L, zinc chloride 10-12g / L, alkylphenol polyoxyethylene ether OP-101-2g / L, pH value 5-6, and water balance.

Embodiment 3

[0041] Embodiment three, the similarity with embodiment one is no longer repeated, and difference is:

[0042] The plating flux solvent contains ammonium chloride 30-35g / L, zinc chloride 12-15g / L, alkylphenol polyoxyethylene ether op-102-2.5g / L, pH value 5-6, and water balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com