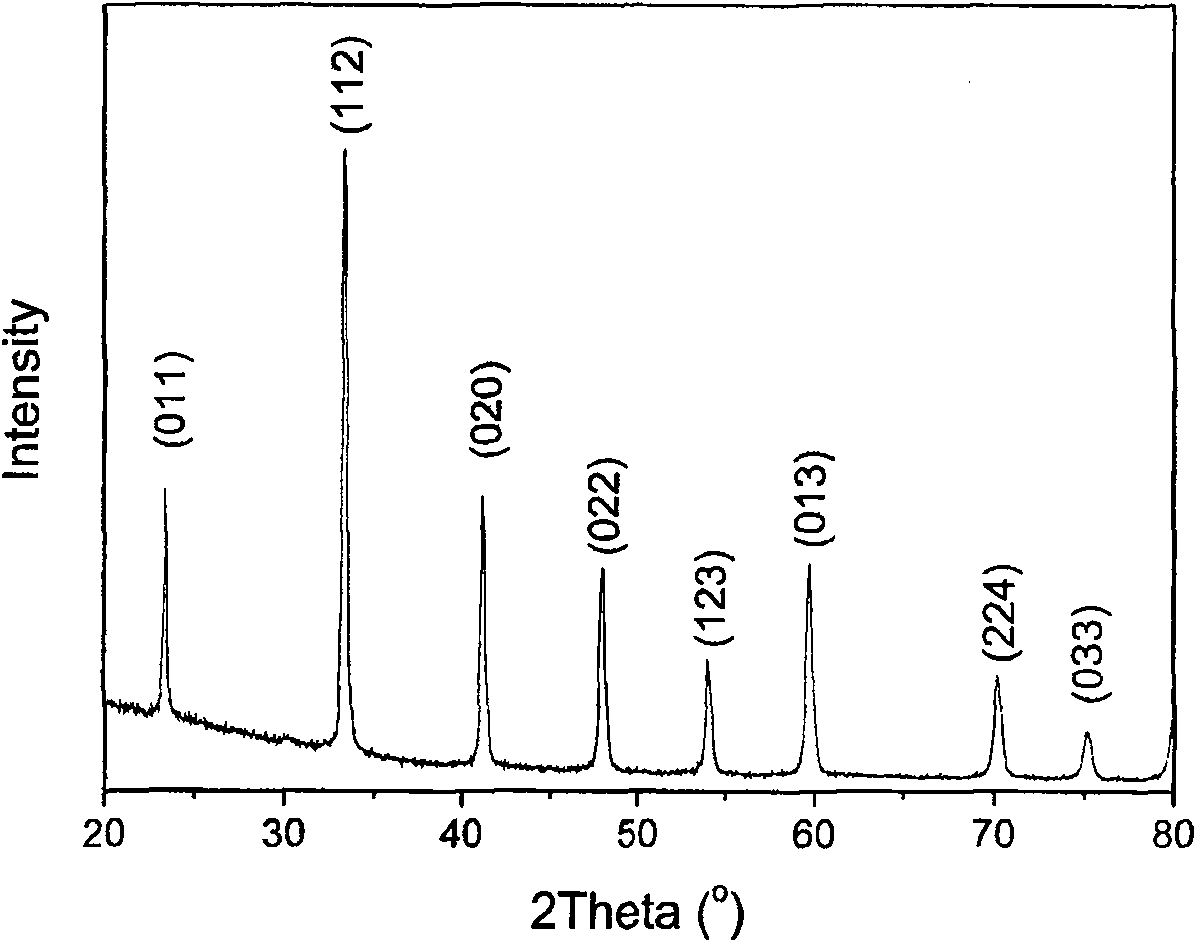

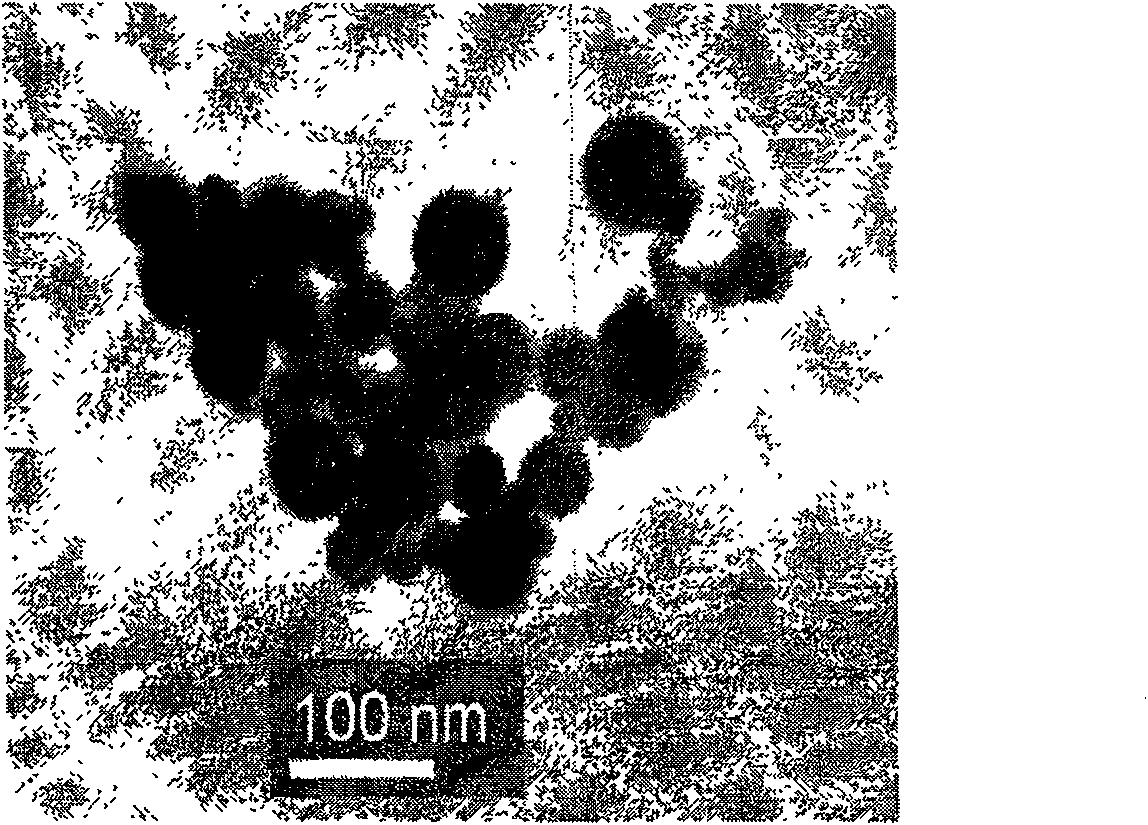

Method for preparing nano aluminate lanthanum powder

A nano-aluminum and powder technology, applied in the field of nano-materials, can solve the problems of large size, irregular shape and high temperature of lanthanum aluminate powder, and achieve the effects of reducing production cost, regular shape and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: After mixing and stirring 8 grams of Span 80, 12 grams of Tween 80, 10 grams of n-butanol, and 70 grams of cyclohexane at room temperature, add 11.1 grams of a concentration of 0.3mol / L lanthanum nitrate and aluminum nitrate. Aqueous solution (the molar ratio of lanthanum nitrate and aluminum nitrate is 1:1), after stirring, microemulsion A is made; at room temperature, 8 grams of Span 80, 12 grams of Tween 80, 10 grams of n-butanol, and 70 grams of cyclohexane are mixed After stirring, add 11.1 grams of ammonia water with a concentration of 2mol / L as the water phase, and make microemulsion B after stirring; add B into A under stirring, and control the pH value to 9.5 until uniform and transparent microemulsion C is formed; 20g Add acetone to microemulsion C, separate with a centrifuge after stirring, and draw the supernatant. The precipitate was washed with 10 g of acetone-ethanol mixture with a volume ratio of 1:1, and then centrifuged, and the supernata...

Embodiment 2

[0018] Example 2: After mixing and stirring 8 grams of Span 80, 12 grams of Tween 80, 10 grams of n-butanol, and 60 grams of cyclohexane at room temperature, add 10 grams of a mixed aqueous solution of 0.15 mol / L lanthanum nitrate and aluminum nitrate (The molar ratio of lanthanum nitrate and aluminum nitrate is 1: 1), after stirring, microemulsion A is made; At room temperature, 8 gram Span 80, 12 gram Tween 80, 10 gram n-butanol, 60 gram cyclohexane are mixed After stirring, add 10 grams of ammonia water with a concentration of 3mol / L as the water phase, and make microemulsion B after stirring; add B to A under stirring, and control the pH value to 9.5 until a uniform and transparent microemulsion C is formed; 20g Add acetone to microemulsion C, separate with a centrifuge after stirring, and draw the supernatant. The precipitate was washed with 10 g of acetone-ethanol mixture with a volume ratio of 1:1, and then centrifuged, and the supernatant was still drawn after centrifu...

Embodiment 3

[0019] Example 3: After mixing and stirring 5 grams of Span 80, 15 grams of Tween 80, 11 grams of n-butanol, and 70 grams of cyclohexane at room temperature, add 8 grams of a mixed aqueous solution of 0.2 mol / L lanthanum nitrate and aluminum nitrate (the molar ratio of lanthanum nitrate and aluminum nitrate is 1: 1), after stirring, microemulsion A is made; at room temperature, 5 grams of Span 80, 15 grams of Tween 80, 11 grams of n-butanol, and 70 grams of cyclohexane are mixed and stirred Finally, add 8 grams of ammonia water with a concentration of 1mol / L as the water phase, stir to make microemulsion B; add B to A under stirring, and control the pH value to 10.5 until a uniform and transparent microemulsion C: mix 20g of acetone Add microemulsion C, stir and separate with a centrifuge, and draw the supernatant. The precipitate was washed with 10 g of acetone-ethanol mixture with a volume ratio of 1:1, and then centrifuged, and the supernatant was still drawn after centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com