Light aggregate concrete mould wall body construction material and its production technology

A concrete formwork and lightweight aggregate technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of unreasonable raw material structure, low compressive strength and high price of formwork wall components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

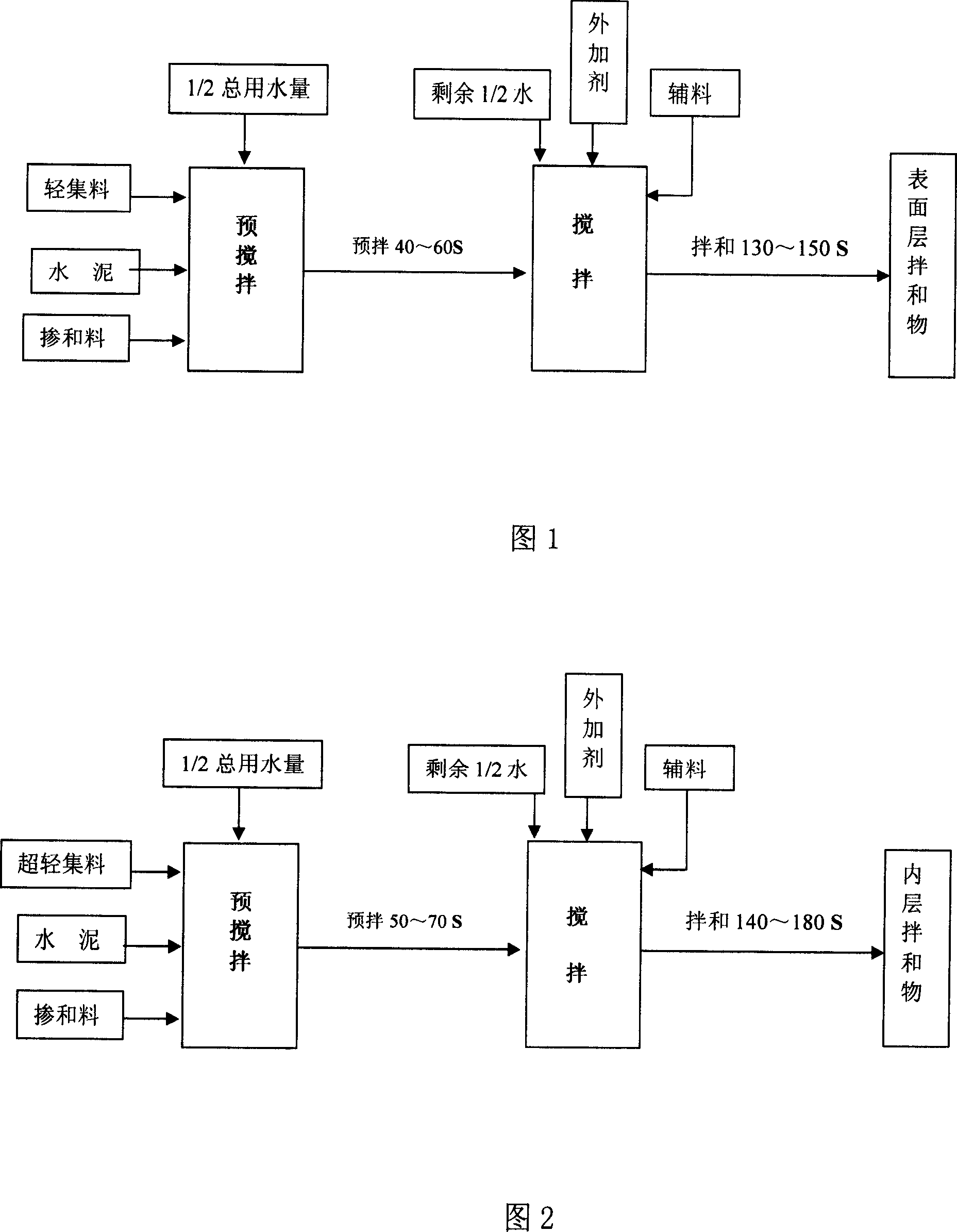

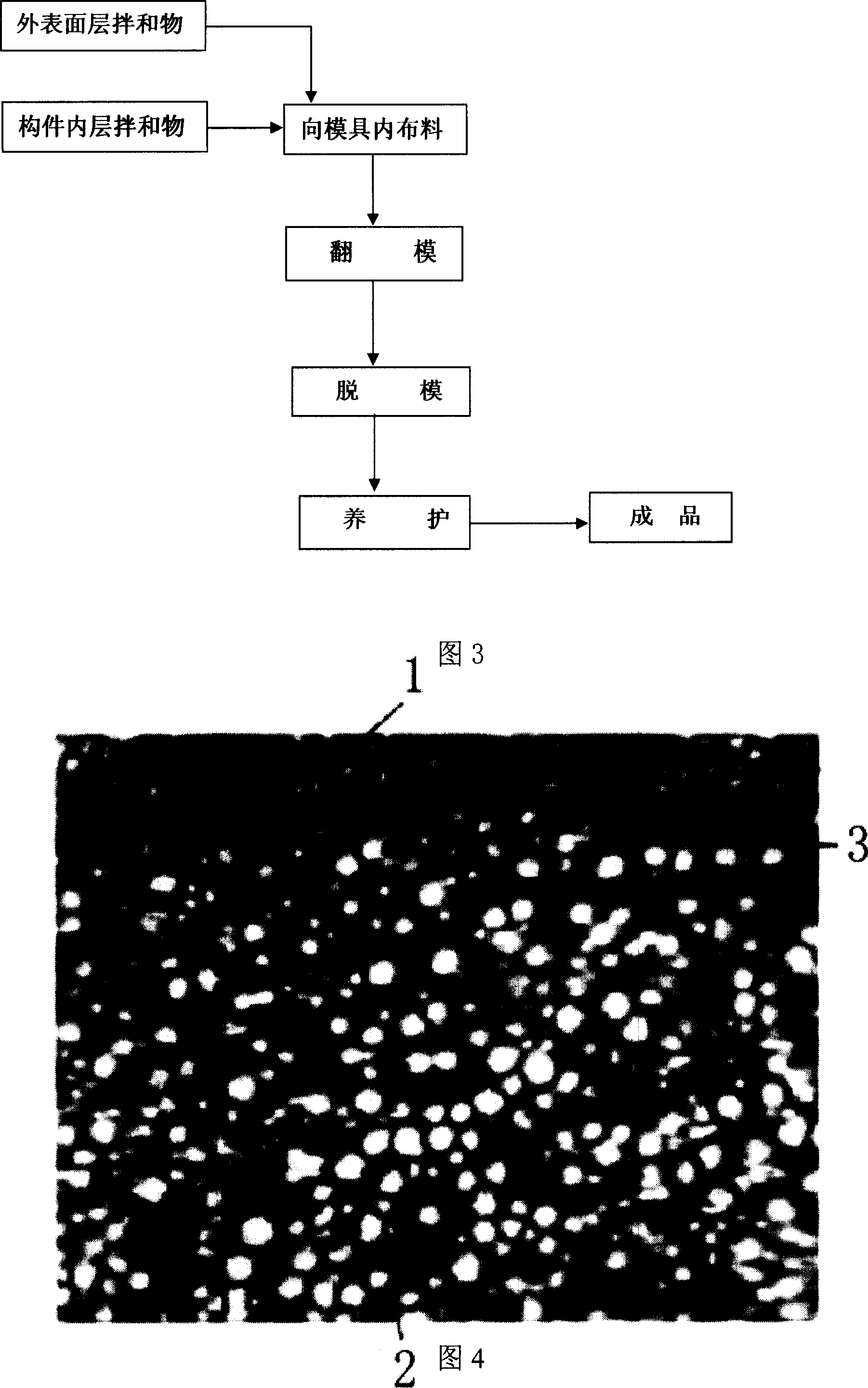

Method used

Image

Examples

Embodiment 1

[0057] (1) The weight ratio of the outer surface layer material is as follows:

[0058] Cement: 42.5# Portland cement 35%, light aggregate: fly ash ceramsite 35%, admixture: fly ash 10.5%, auxiliary material A: vinyl acetate copolymer (EVA) 1.15%, auxiliary material B: poly Propylene (PP) fiber 0.1%, additive: naphthalene superplasticizer (JFA) 0.25%, water 18%.

[0059] Fly ash ceramsite requires a particle size of less than φ3.6mm, and requires a 2.0mm square hole sieve residue to be greater than 70%, a 1.0mm square hole sieve residue to be greater than 90%, and the fly ash requires an apparent density of less than 2600kg / m3 , The specific surface area is greater than 300m2 / kg, polypropylene (PP) fiber requires a length of 8-12mm and a diameter of 2-5μm.

[0060] (2) The weight ratio of the inner layer materials of the components is as follows:

[0061] Cement: 42.5# Portland cement 56%, ultra-light aggregate: polystyrene foam 3.4%, admixture: fly ash 11%, auxiliary materi...

Embodiment 2

[0074] (1) The weight ratio of the outer surface layer material is as follows:

[0075] Cement: 42.5# Portland cement 37%, light aggregate: pumice 34%, admixture: fly ash 6% and slag fine powder 3%, auxiliary material A: vinyl acetate copolymer (EVA) 1.45%, auxiliary material B : Polyester fiber (PE) 0.15%, additives: naphthalene superplasticizer (JFA) 0.4%, water 18%.

[0076] The particle size of pumice is required to be less than φ3.6mm, and the sieve allowance of 2.0mm square hole sieve is required to be greater than 70%, and the cumulative sieve allowance of 1.0mm square hole sieve is greater than 90%. 300m2 / kg, polyester fiber (PE) requires a length of 8-12mm and a diameter of 2-5μm.

[0077] (2) The weight ratio of the inner layer materials of the components is as follows:

[0078] Cement: 42.5# Portland cement 58%, ultra-light aggregate: expanded perlite 3%, admixture: fly ash 5% and slag fine powder 5%, auxiliary material C: polyvinyl alcohol (PVA) 1.72%, Excipient...

Embodiment 3

[0091] (1) The weight ratio of the outer surface layer material is as follows:

[0092] Cement: 42.5# Portland cement 33%, light aggregate: porous volcanic rock particles 36%, admixture: fly ash 10.28%, auxiliary material A: vinyl acetate copolymer (EVA) 1.2%, auxiliary material B: polypropylene ( PP) fiber 0.12%, additives: naphthalene superplasticizer (JFA) 0.4%, water 19%.

[0093] The particle size of porous volcanic rock is required to be less than φ3.6mm, and the sieve residue of 2.0mm square hole is required to be greater than 70%, the cumulative residue of 1.0mm square hole sieve is greater than 90%, and the apparent density of fly ash is required to be less than 2600kg / m The surface area is greater than 300m2 / kg, and the polypropylene (PP) fiber requires a length of 8-12mm and a diameter of 2-5μm.

[0094] (2) The weight ratio of the inner layer materials of the components is as follows:

[0095] Cement: 42.5# Portland cement 53%, ultra-light aggregate: polystyrene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com