Soluble polyacrylic cyanide composite and preparation process thereof

A technology of polyacrylonitrile and composites, which is applied in the field of polyacrylonitrile spinning, and can solve the problems of reducing the mechanical and thermal properties of polymers, difficulty in controlling the process, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

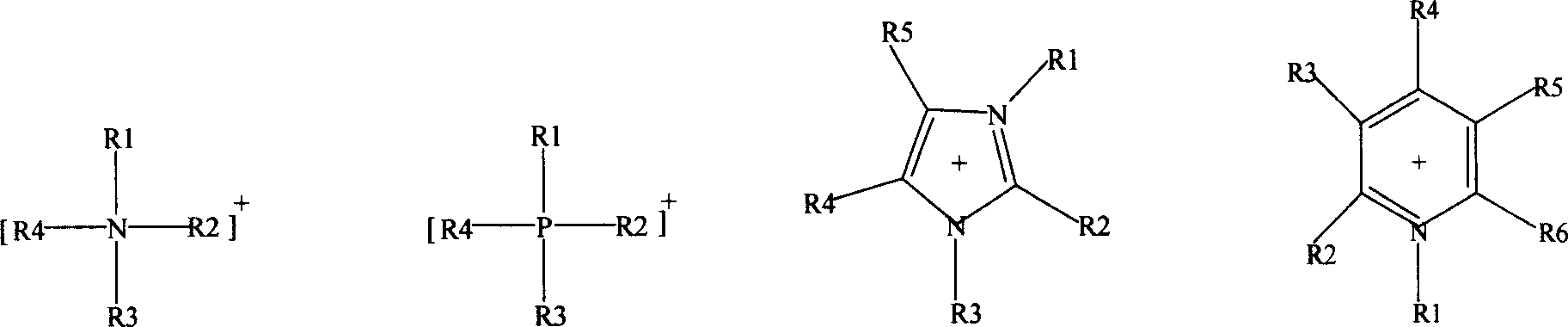

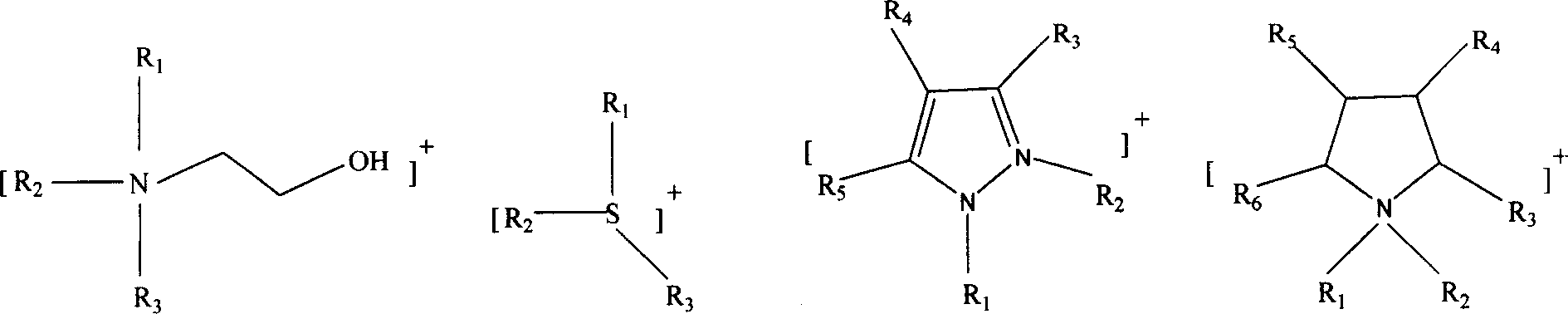

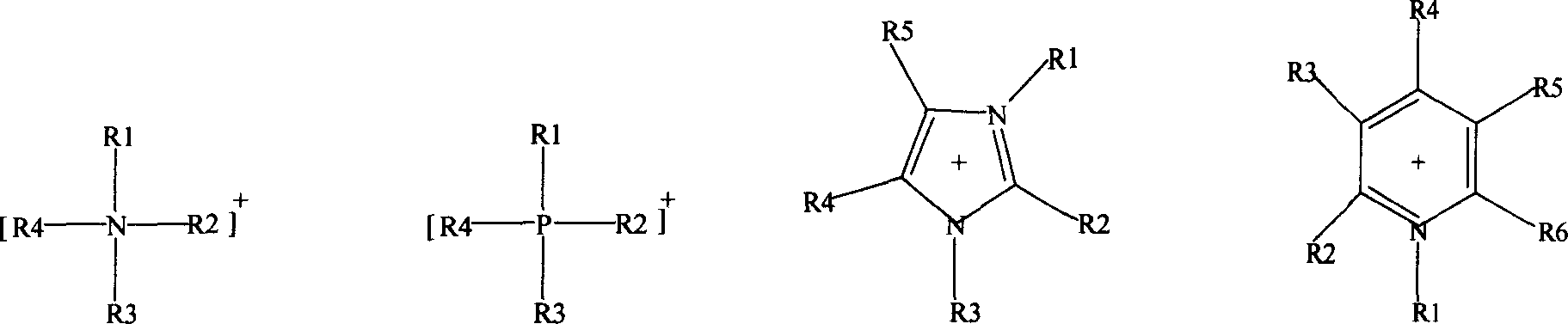

[0032] The following ionic liquids were used to prepare polyacrylonitrile / ionic liquid complexes:

[0033]

[0034] Mix polyacrylonitrile and ionic liquid, stir evenly, and cool to room temperature to obtain polyacrylonitrile / ionic liquid compound.

[0035] Example

Embodiment 5~8

[0037] The following ionic liquids were used to prepare polyacrylonitrile / ionic liquid complexes:

[0038]

[0039] Example

[0040] The preparation method is the same as in Example 1.

Embodiment 9~12

[0042] The following ionic liquids were used to prepare polyacrylonitrile / ionic liquid complexes:

[0043]

[0044] Example

[0045] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com