Composite doped cerium oxide electrolyte and preparation method thereof

A technology of compound doping and compound oxide is applied in the field of compound doping cerium oxide electrolyte and its preparation, which can solve the problems of reducing the ionic conductivity and efficiency of cerium oxide, so as to improve the ionic conductivity, improve the yield and prepare simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

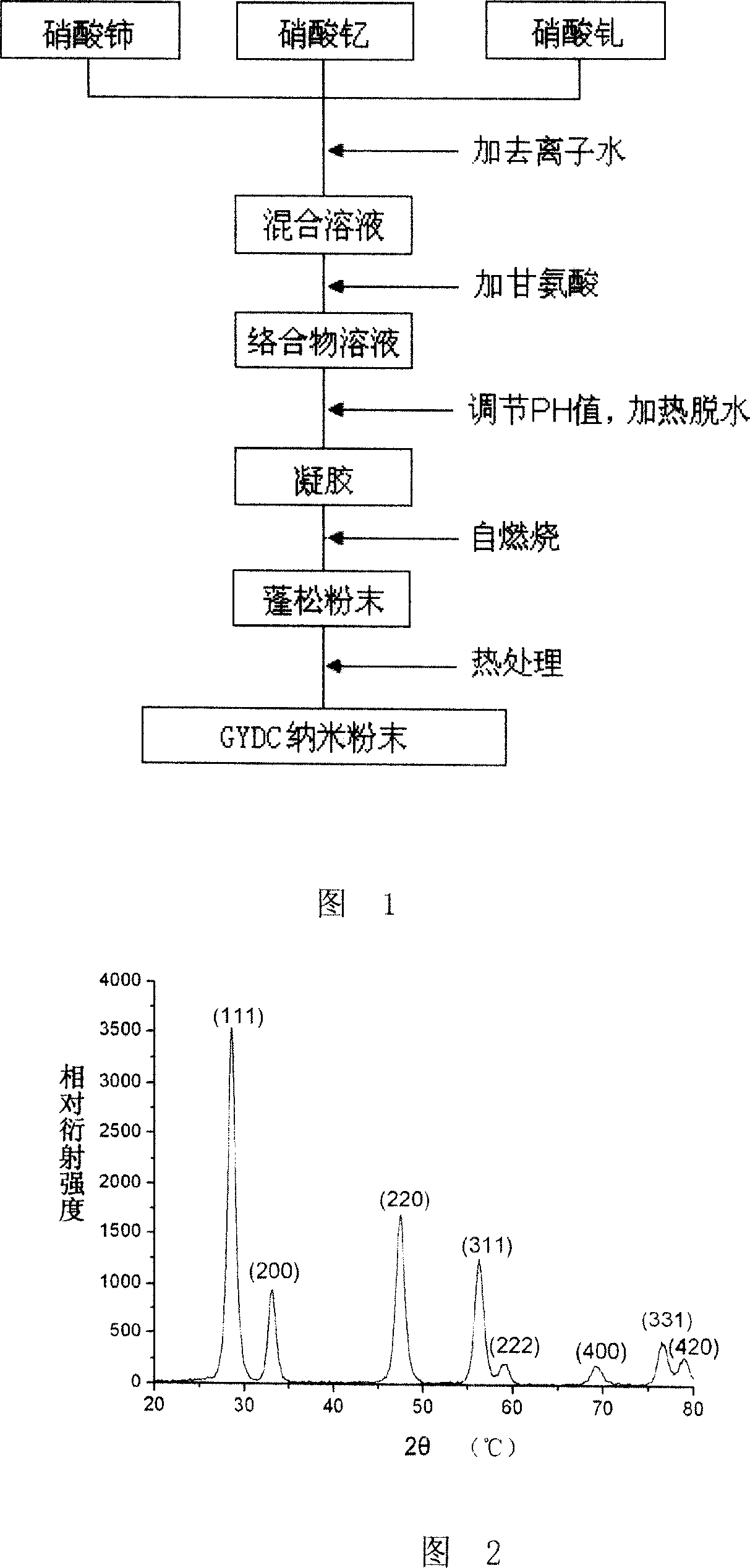

[0026] Embodiment 1, preparation meets Ce 0.8 Gd 0.05 Y 0.15 o 1.9 Stoichiometric ratio of gadolinium, yttrium composite doped ceria electrolyte

[0027] According to the stoichiometric ratio of cerium, gadolinium and yttrium ions in the molar ratio of 0.8:0.05:0.15, weigh cerium nitrate, gadolinium nitrate and yttrium nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, form a clear solution and add Glycine, so that the molar ratio of glycine and nitrate ions is 0.2:1, adjust the pH value of the solution to 7.5 with ammonia water, then heat and evaporate at 80°C to remove water until a tan viscous gel is formed, and the water in the gel is evaporated to dryness Finally, move it to a constant temperature electric furnace at 200°C. The dry gel begins to expand, boil, and smoke in about 3 minutes, and then generates a flame and discharges a large amount of gas. After the reaction is completed, a light yellow fluffy powder is formed. After the p...

Embodiment 2

[0028] Embodiment 2, preparation meets Ce 0.8 Gd 0.1 Y 0.1 o 1.9 Stoichiometric ratio of gadolinium, yttrium composite doped ceria electrolyte

[0029] According to the stoichiometric ratio of cerium, gadolinium and yttrium ions in the molar ratio of 0.8:0.1:0.1, weigh cerium nitrate, gadolinium nitrate and yttrium nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, form a clear solution and add Glycine, so that the molar ratio of glycine and nitrate ions is 0.3:1, adjust the pH value of the solution to 7.5 with ammonia water, then heat and evaporate at 80°C to remove water until a tan viscous gel is formed, and the water in the gel is evaporated to dryness Finally, move it to a constant temperature electric furnace at 200°C. The dry gel begins to expand, boil, and smoke in about 3 minutes, and then generates a flame and discharges a large amount of gas. After the reaction is completed, a light yellow fluffy powder is formed. After the powde...

Embodiment 3

[0030] Embodiment 3, preparation meets Ce 0.8 Gd 0.15 Y 0.05 o 1.9 Stoichiometric ratio of gadolinium, yttrium composite doped ceria electrolyte

[0031] According to the stoichiometric ratio of cerium, gadolinium and yttrium ions in the molar ratio of 0.8:0.15:0.05, weigh cerium nitrate, gadolinium nitrate and yttrium nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, form a clear solution and add Glycine, so that the molar ratio of glycine and nitrate ions is 0.5:1, adjust the pH value of the solution to 8.5 with ammonia water, then heat and evaporate at 80°C to remove water until a tan viscous gel is formed, and the water in the gel is evaporated to dryness Finally, move it to a constant temperature electric furnace at 200°C. The dry gel begins to expand, boil, and smoke in about 3 minutes, and then generates a flame and discharges a large amount of gas. After the reaction is completed, a light yellow fluffy powder is formed. After the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com