Multiple proportional layered composite manufactured amide paper of aramid fiber

A kind of aramid paper, multi-proportion technology, applied in the direction of papermaking, paper machine, layered products, etc., can solve the problems of poor mechanical properties, low elongation at break, high degree of molecular structure symmetry and orientation, and achieve the state of interface bonding Good, smooth and homogeneous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

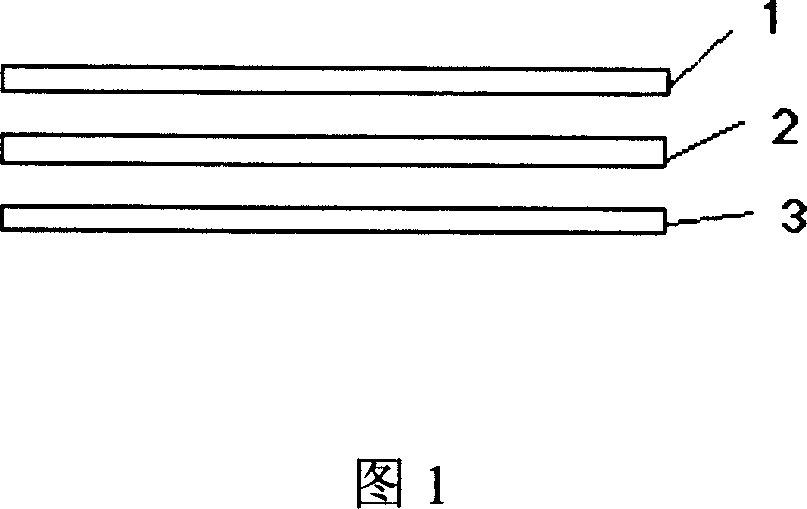

[0020] Embodiment 1, at first with aramid fibril and length is 8mm, the aramid chopped fiber that fineness is 7 deniers namely polym-phenylene isophthalamide fiber is respectively dispersed in water and loosened into slurry, made Mass concentration is 1% aramid fibrid slurry and mass concentration is 8% aramid fibrid slurry; then by mass percentage, 30% aramid fibrid slurry and 70% chopped fiber The slurry is mixed, and the core layer 2 is formed on the Internet by the common papermaking method; then 40% of the aramid precipitated fiber slurry and 60% of the chopped fiber slurry are mixed according to the mass percentage, and the ordinary papermaking method is used on the Internet. Surface layer 1 and bottom layer 3 are formed; the formed core layer 2, surface layer 1 and bottom layer 3 are compounded from top to bottom according to the order of surface layer 1, core layer 2 and bottom layer 3 respectively, wherein Surface layer 1 and bottom layer 3 account for 67% of the weig...

Embodiment 2

[0021] Embodiment 2, at first aramid fibrid and length are 12mm, and fineness is the aramid short-cut fiber of 3 deniers, namely polym-phenylene isophthalamide fiber, is respectively dispersed in water and loosened into slurry, and made Mass concentration is that 1.3% aramid fibrid slurry and mass concentration are 6% aramid fibrid pulp; then by mass percentage, 45% aramid fibrid pulp and 55% chopped fiber The slurry is mixed, and the core layer 2 is formed on the Internet by the ordinary papermaking method; then 60% of the aramid precipitated fiber slurry and 40% of the chopped fiber slurry are mixed according to the mass percentage, and the ordinary papermaking method is used on the Internet. Surface layer 1 and bottom layer 3 are formed; the formed core layer 2, surface layer 1 and bottom layer 3 are compounded from top to bottom according to the order of surface layer 1, core layer 2 and bottom layer 3 respectively, wherein The surface layer 1 and the bottom layer 3 accoun...

Embodiment 3

[0022] Embodiment 3, at first with aramid fibril and length is 4mm, the aramid chopped fiber that fineness is 10 deniers namely polym-phenylene isophthalamide fiber is respectively dispersed in water and loosened into slurry, made Mass concentration is that 1.2% aramid fiber fibrid slurry and mass concentration are 2% aramid fibrid fiber slurry; then by mass percentage, 20% aramid fibrid fiber slurry and 80% chopped fiber The slurry is mixed, and the core layer 2 is formed on the Internet by the common papermaking method; then 50% of the aramid precipitated fiber slurry and 50% of the chopped fiber slurry are mixed according to the mass percentage, and the ordinary papermaking method is used on the Internet Surface layer 1 and bottom layer 3 are formed; the formed core layer 2, surface layer 1 and bottom layer 3 are compounded from top to bottom according to the order of surface layer 1, core layer 2 and bottom layer 3 respectively, wherein Surface layer 1 and bottom layer 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com