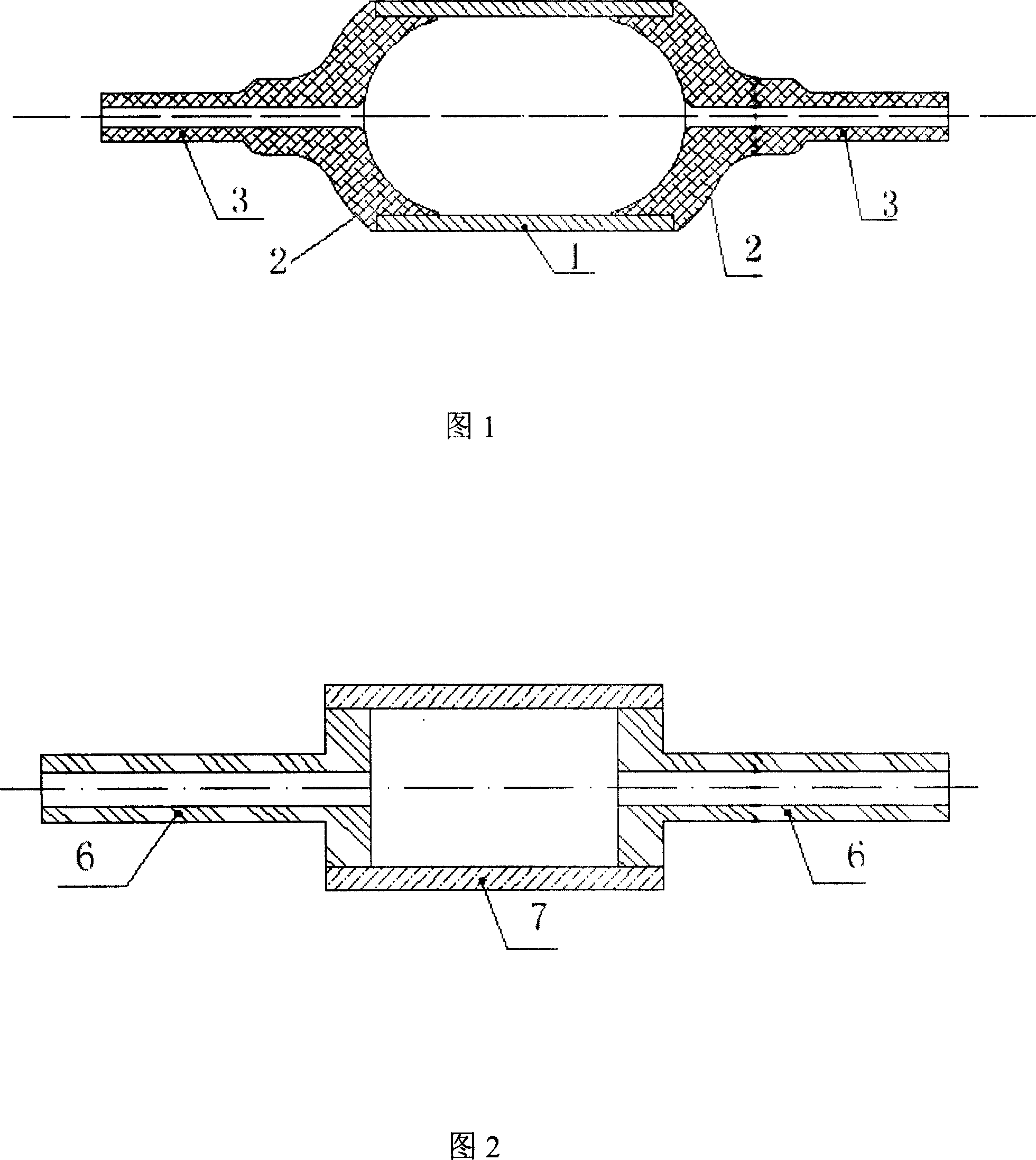

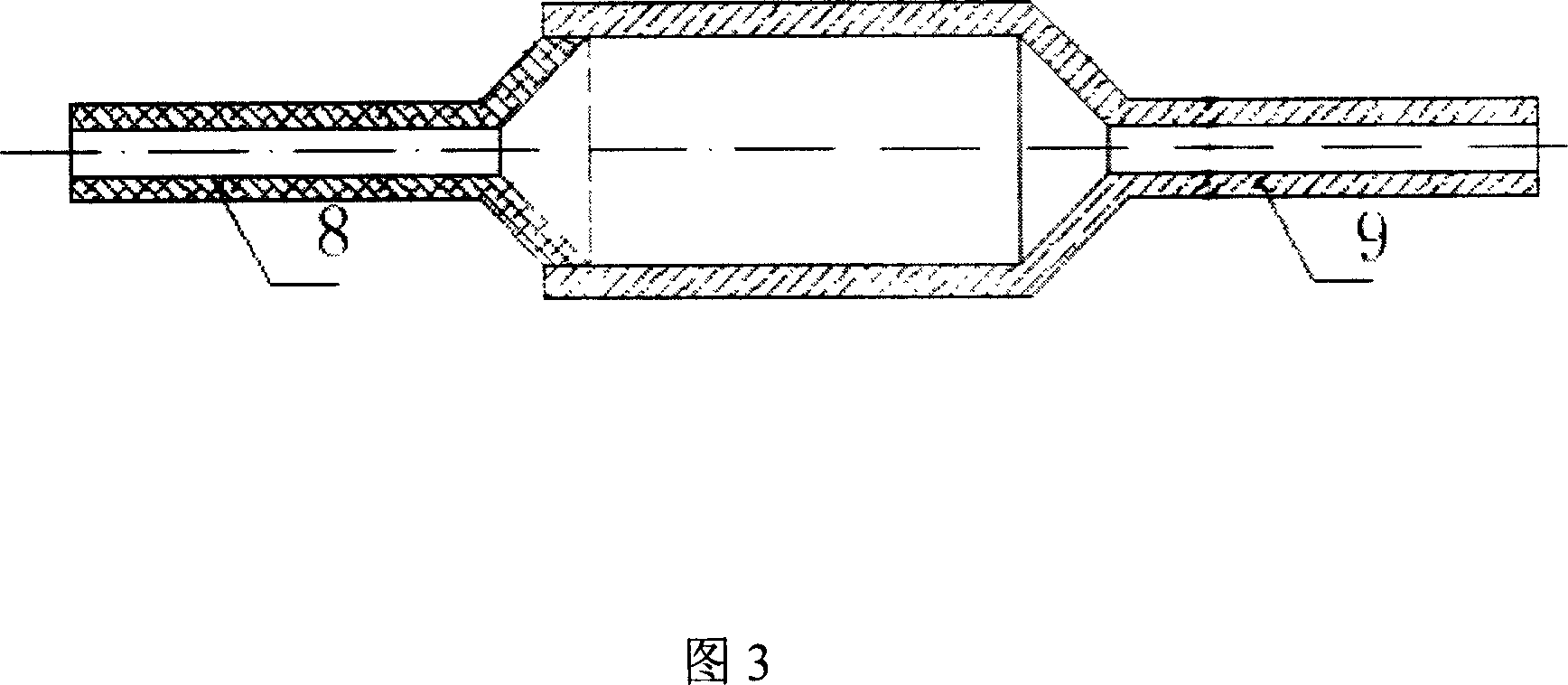

Semi-transparent ceramic arc tube and its producing method

A manufacturing method and translucent technology, applied in the manufacture of discharge tubes/lamps, electrode systems, cold cathodes, etc., can solve the problems of low production efficiency, inability to guarantee the coaxiality and dimensional accuracy of the three components, etc. The effect of long life, low light decay and high color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Add 0.1% magnesium oxide (MgO) to ultrafine alumina powder with a purity greater than 99.99%, mix it with an organic binder, and granulate it. Add 5% polyethylene, 8% paraffin and 1% stearic acid to the batch of main parts; add 4.5% polyethylene, 7.5% paraffin and 1% stearic acid to the batch of end parts.

[0039] B. Perform injection molding at 130° C. and 80 MPa to obtain blanks of each component.

[0040] C. Assemble the end face part and the main part directly, heat up to 600°C at a heating rate of 30°C / hour for degreasing, then raise the temperature to 1300°C at a heating rate of 100°C / hour, and hold for 2 hours for pre-sintering.

[0041] D. Put the pre-sintered arc tube into a hydrogen sintering furnace and keep it warm at 1780°C for 3 hours.

[0042] The density of the transparent alumina ceramic arc tube obtained by the above manufacturing method is 3.985g / cm 3 , the average grain size is 20 microns to 30 microns, the three-point bending strength is 400MP...

Embodiment 2

[0045] Add 0.01% magnesium oxide (MgO) and 0.02% Y to ultrafine alumina powder with a purity greater than 99.99% 2 o 3 Afterwards, it is mixed with an organic binder and granulated. Add 5% polyethylene, 8% paraffin and 1% stearic acid to the batch of main parts; add 4.5% polyethylene, 7.5% paraffin and 1% stearic acid to the batch of end parts.

[0046] Using the same injection molding, assembly, degreasing and sintering process as in Example 1, a translucent alumina ceramic arc tube was obtained.

[0047]The density of the transparent alumina ceramic arc tube obtained by the above manufacturing method is 3.986g / cm 3 , the average grain size is 20 microns to 40 microns, the three-point bending strength is 380MPa, and the linear light transmittance is 32%.

Embodiment 3

[0049] A. Add 0.005% magnesium oxide (MgO) and 0.01% La to ultrafine alumina powder with a purity greater than 99.99% 2 o 3 After that, it is mixed with organic binder and granulated. Add 4.8% polyethylene, 8.4% paraffin and 1% stearic acid to the batch of main parts; add 4.2% polyethylene, 7.8% paraffin and 1% stearic acid to the batch of end parts.

[0050] B. Perform injection molding at 120° C. and 60 MPa to obtain blanks of various parts.

[0051] C. Assemble the end face part and the main part directly, heat up to 600°C at a heating rate of 25°C / hour for degreasing, then raise the temperature to 1300°C at a heating rate of 100°C / hour, hold for 2 hours for pre-sintering,

[0052] D. Put the pre-sintered arc tube into a hydrogen sintering furnace and keep it warm at 1820°C for 3 hours.

[0053] The density of the transparent alumina ceramic arc tube obtained by the above manufacturing method is 3.987g / cm 3 , the average grain size is 30 microns to 40 microns, the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com