Pressure reduction vessel and pressure reduction processing apparatus

A container and internal decompression technology, applied in pressure vessels/vacuum vessels, pressure vessels used in chemical processes, instruments, etc., can solve problems such as difficulty in high-precision machining, increase in the number of manufacturing processes for decompression vessels, and particle generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

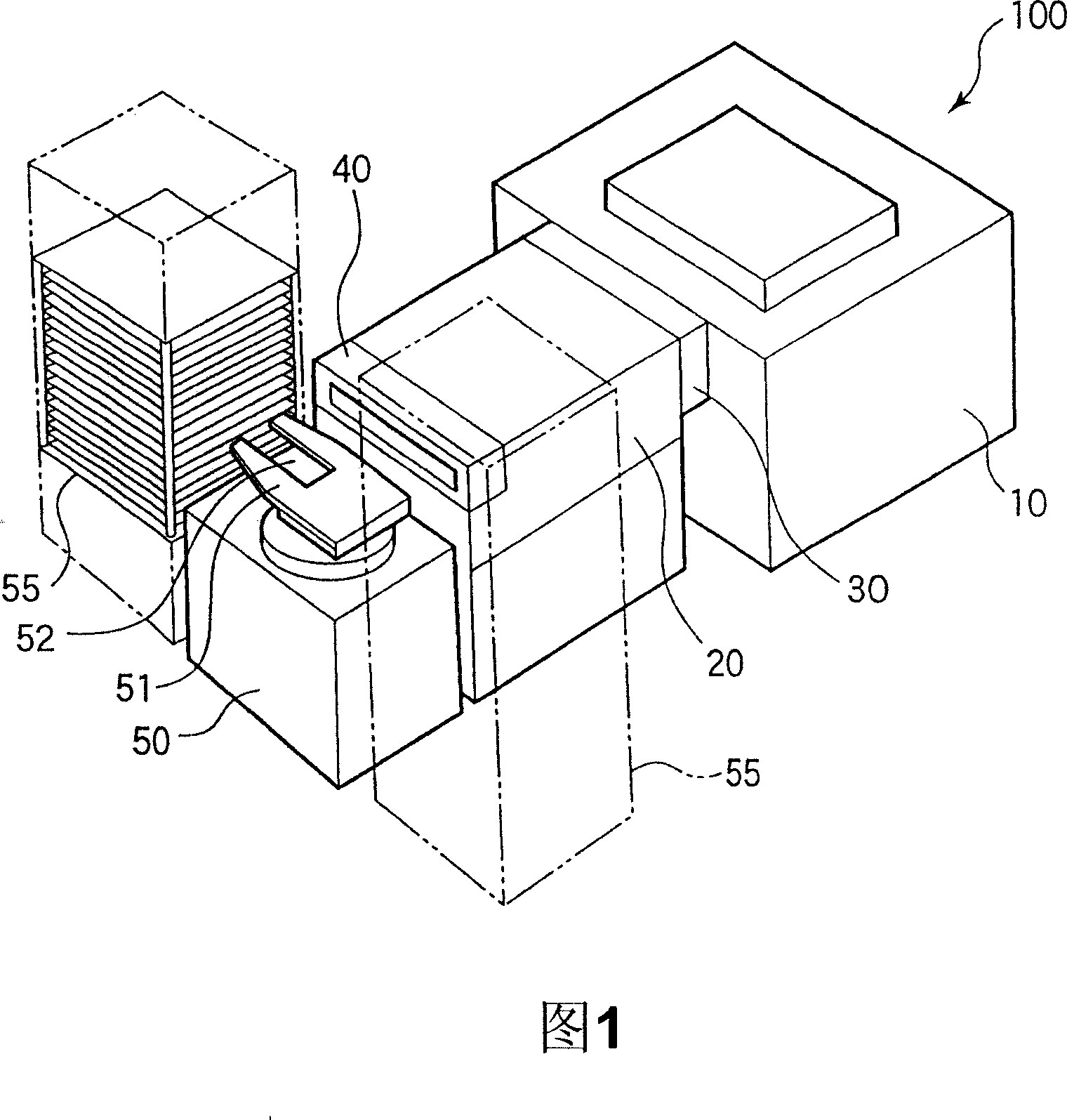

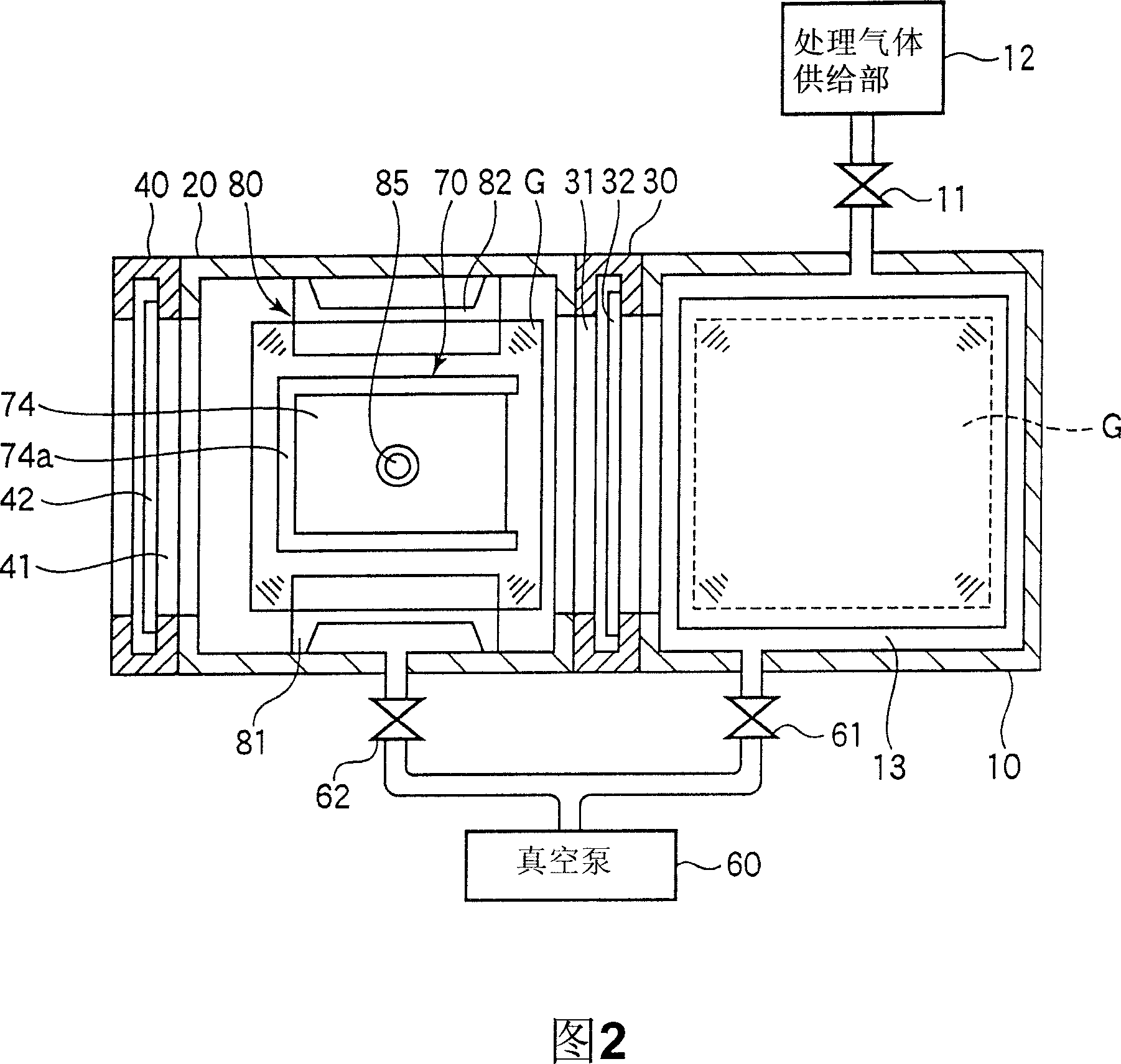

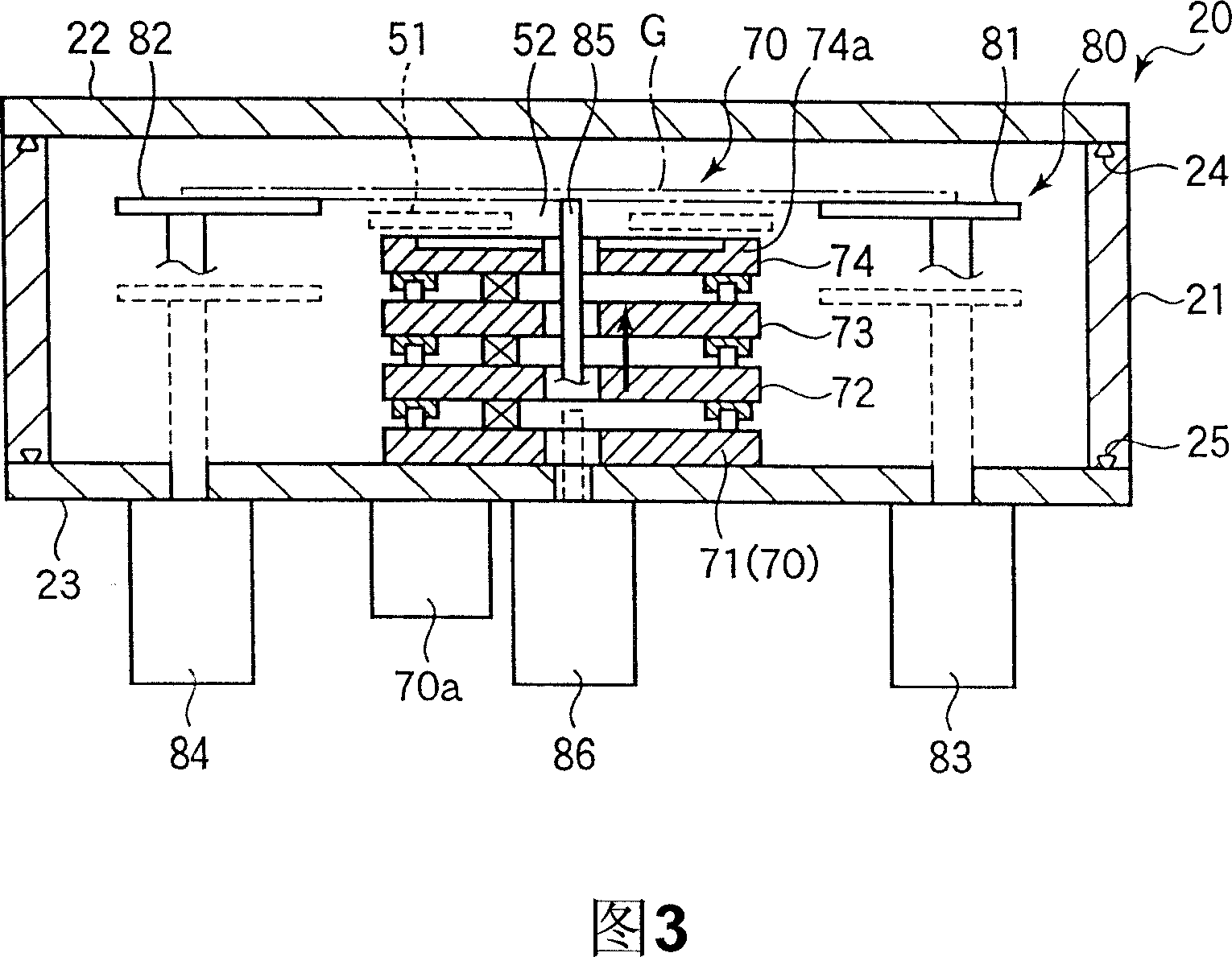

[0059] 1 is a perspective view showing the appearance of a vacuum processing apparatus according to an embodiment of the present invention, FIG. 2 is a horizontal sectional view of the vacuum processing apparatus of FIG. 1 , FIG. 3 is a longitudinal sectional view of a vacuum preparation chamber of the vacuum processing apparatus, and FIG. 4 It is a perspective view showing a configuration example of a substrate transfer mechanism of a substrate transfer device arranged in a vacuum processing chamber.

[0060] The vacuum processing apparatus 100 of this embodiment includes: a vacuum processing chamber 10 for performing desired vacuum processing such as plasma etching processing and thin film forming processing on a substrate G such as an LCD glass substrate under a vacuum atmosphere; , the load lock chamber 20 functioning as a vacuum preparation chamber; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com