Lead-containing selenide glass and preparing process thereof

A technology of selenide and glass, which is applied in the field of lead-containing selenide glass and its preparation, and achieves the effects of simple processing, strong covalency, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Formulation design:

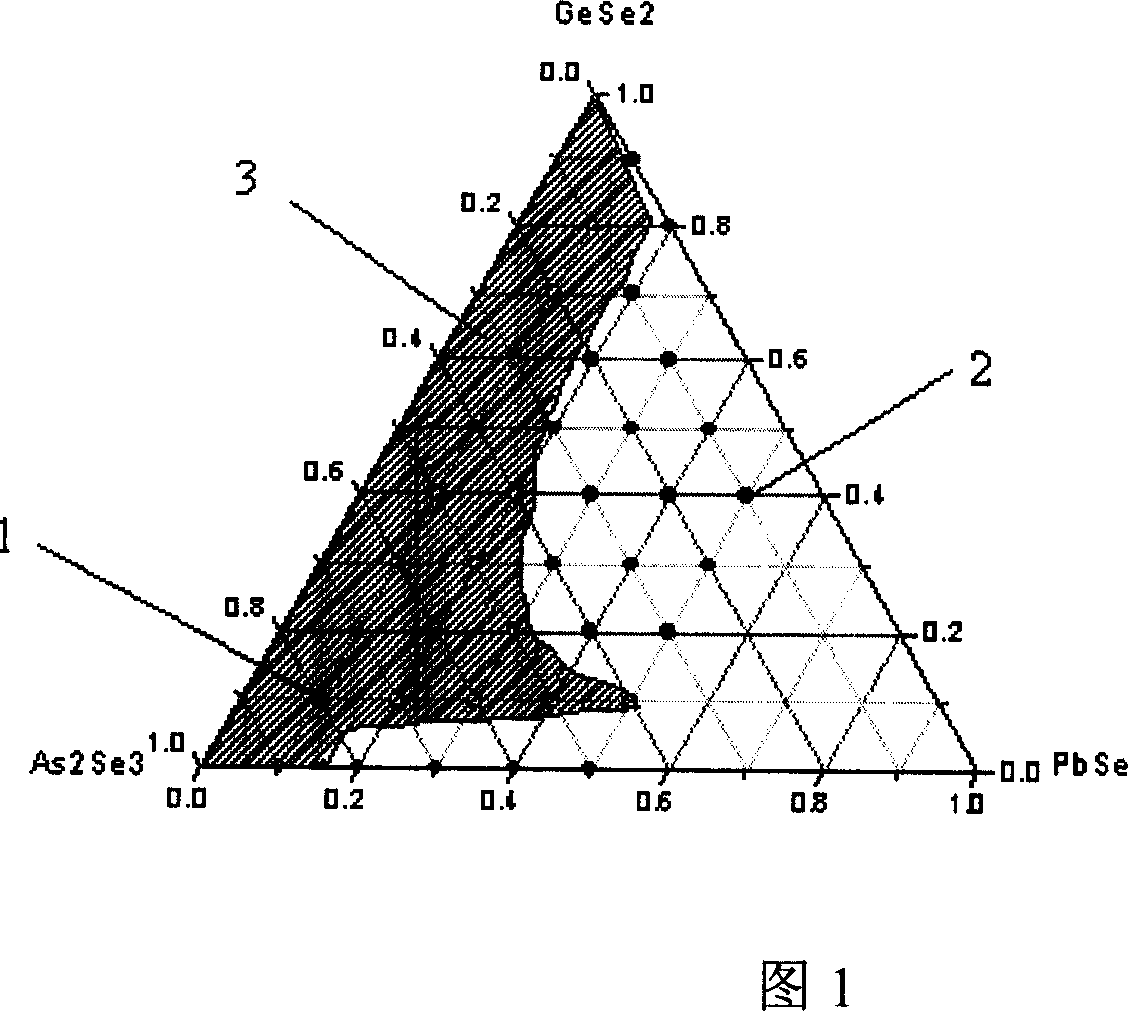

[0025] Using the quaternary system of selenium, germanium, arsenic and lead, the components are designed as follows:

[0026] Table 1 Glass composition of Example 1 (at%)

[0027] GeSe 2

As 2 Se 3

PdS

20

70

10

[0028] Batch preparation:

[0029] High-purity (>99.999%) elemental selenium, germanium, arsenic and lead were respectively used as raw materials, and the formula was calculated according to the composition shown in Table 1.

[0030] Raw material purification and drying:

[0031] Put the quartz tubes filled with Se and As respectively into a high-temperature furnace, heat while vacuuming, and raise the temperature to 300°C, the oxides of Se / As are distilled out, and the raw materials are purified. Then accurately weigh the purified raw materials according to the stoichiometric ratio of the designed composition, add an appropriate amount of oxygen scavenger Mg, Zr, etc. (based on the w...

Embodiment 2~7

[0043] In the following examples, the glass preparation method is the same as in Example 1, and the different glass compositions and performance test results used are listed in Table 3, Table 4 and Table 5 respectively.

[0044] Table 3 Glass composition (at%) of Examples 2-4

[0045] Numbering

GeSe 2

As 2 Se 3

PdS

2

20

80

0

3

20

60

20

4

20

50

30

5

80

10

10

6

60

30

10

7

40

50

10

[0046] Table 4 Performance test results of glass in Examples 2-4

[0047]

density

(g / cm 3 )

(℃)

Crystallization temperature

(℃)

(℃)

2

4.5255

193.84

-

-

3

4.98062

192.49

283.18

90.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com