Photosensitive monomer and liquid crystal panel, and manufacture method therefor

A technology of photosensitive monomers and substrates, which is applied in the photoplate-making process, optics, and optomechanical equipment on the patterned surface, and can solve problems such as image retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

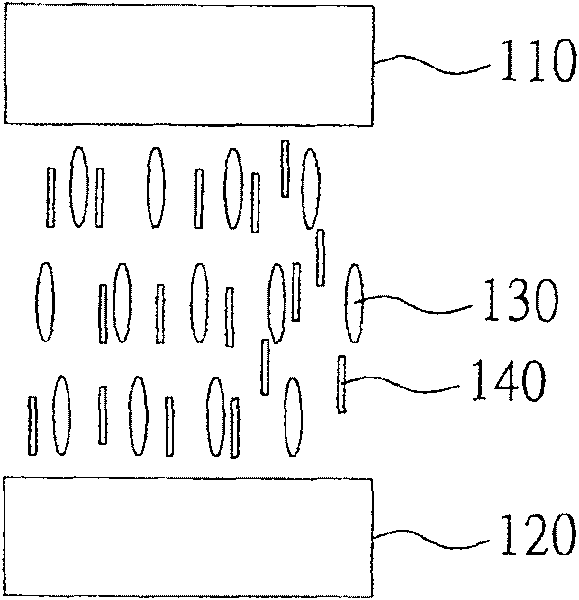

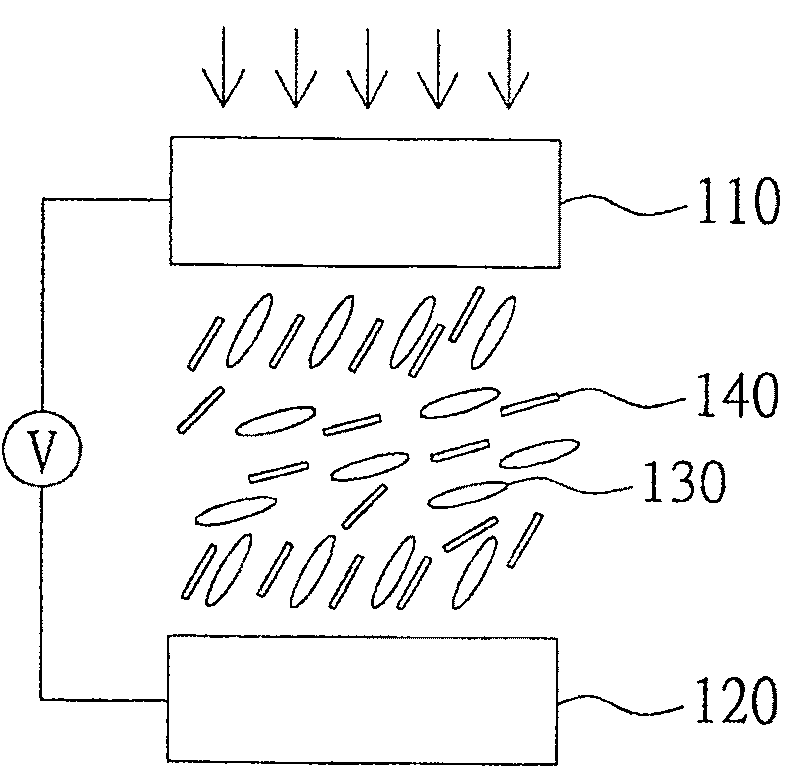

[0033] The present invention mainly proposes a photosensitive monomer, which can shorten the polymerization time and improve the problem of image sticking when applied to the manufacturing method of the liquid crystal panel. The general chemical formula, preferred embodiments and synthesis methods of the photosensitive monomers will be introduced first, and then the method of applying these photosensitive monomers to the fabrication of optoelectronic devices and liquid crystal panels will be introduced.

[0034] photosensitive monomer

[0035] The present invention mainly proposes a photosensitive monomer selected from one of compounds I, II, and III.

[0036] Compound I is represented by the chemical formula:

[0037]

[0038] "L" is a hydrogen atom, a fluorine atom, a chlorine atom, a cyano group, an alkyl group, an alkylcarbonyl group, an alkoxycarbonyl group or an alkoxycarbonyl group having 1 to 7 carbon atoms base (alkylcarbonyloxy). One or more hydrogen atoms in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com