A high desalination polyamide composite reverse osmosis membrane for seawater desalination and its preparation method

A high desalination polyamide, reverse osmosis membrane technology, applied in chemical instruments and methods, reverse osmosis, seawater treatment, etc., to achieve the effect of complete reaction, reduce defects, and improve desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

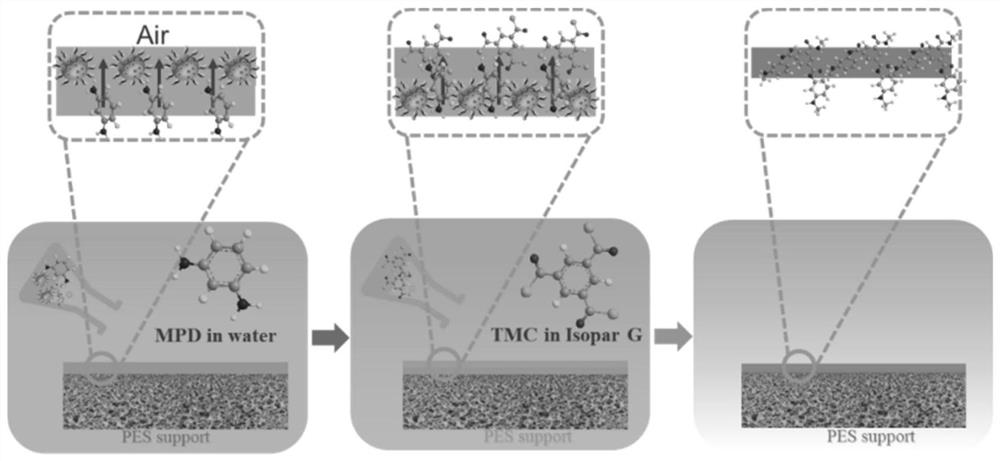

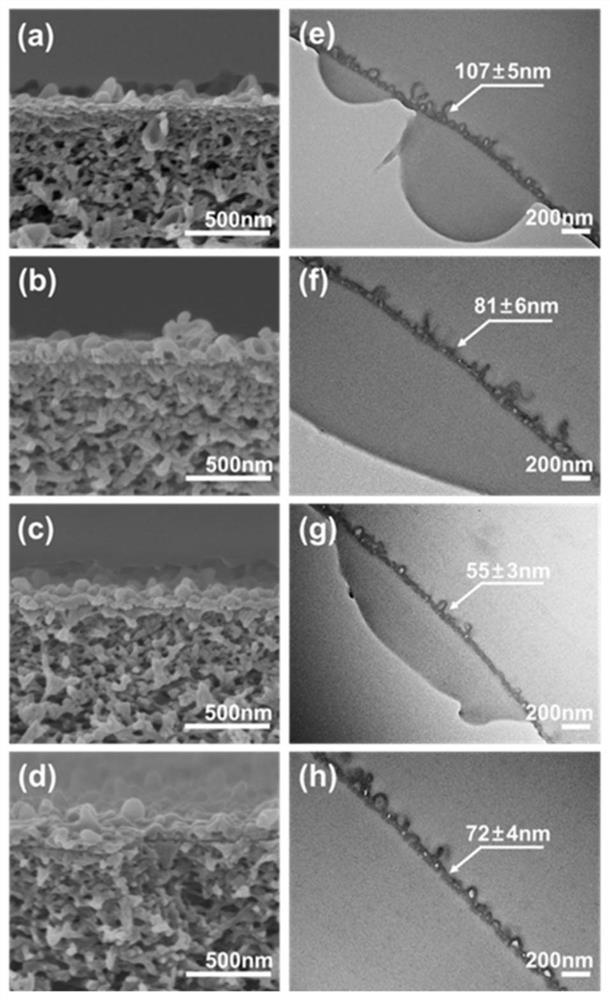

[0026] After fully dissolving 4g of camphorsulfonic acid and 2g of m-phenylenediamine in 98ml of deionized water in turn, finally adjust the pH value with 2g of triethylamine. Pour this solution into the upper surface of the polysulfone porous support layer prepared in advance for 5 minutes, pour off the excess solution, and place it under the ultra-clean workbench for 6 minutes to wait for it to dry in the shade; then add 0.15g of trimesoyl chloride 100ml of Isopar The G solution was poured into the interfacial polymerization, and placed under the ultra-clean workbench for 10 minutes to wait for it to dry in the shade, and then placed in a blast drying oven at 80°C for 10 minutes to obtain a polyamide composite reverse osmosis membrane, which was designated as the M0 membrane.

example 2

[0028] Put 0.05g of sodium dodecyl sulfate (SDS) in 98ml of deionized water first, wait for it to be fully dissolved, then fully dissolve 4g of camphorsulfonic acid and 2g of m-phenylenediamine in turn, and finally use 2g of triethylamine to adjust pH value. Pour this solution into the upper surface of the polysulfone porous support layer prepared in advance for 5 minutes, pour off the excess solution, and place it under the ultra-clean workbench for 6 minutes to wait for it to dry in the shade; then add 0.15g of trimesoyl chloride 100ml of Isopar The G solution was poured into the interfacial polymerization, and placed under the ultra-clean workbench for 10 minutes to wait for it to dry in the shade, and then placed in an 80°C blast drying oven for 10 minutes to obtain a polyamide composite reverse osmosis membrane, which was designated as M1 membrane.

example 3

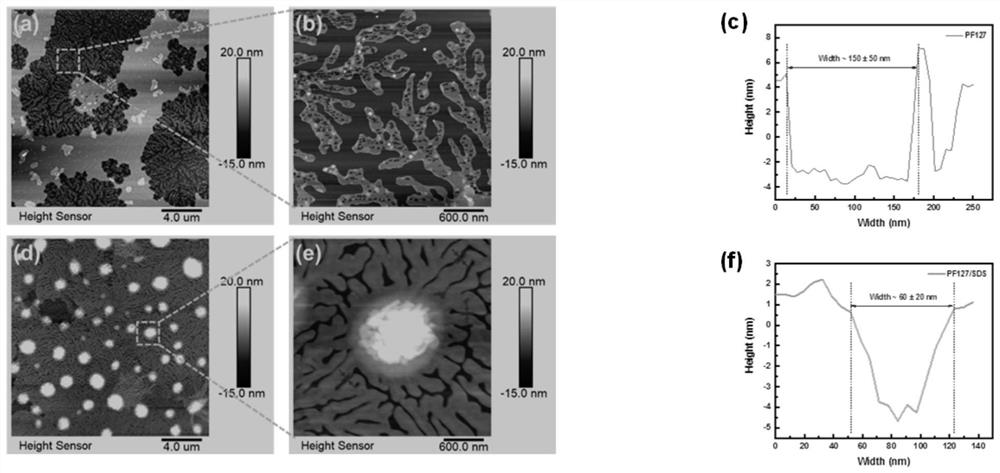

[0030] Put 0.05g of Pluronic F-127 (PF127) in 98ml of deionized water first, wait for it to be fully dissolved, then fully dissolve 4g of camphorsulfonic acid and 2g of m-phenylenediamine in turn, and finally adjust the pH value with 2g of triethylamine . Pour this solution into the upper surface of the polysulfone porous support layer prepared in advance for 5 minutes, pour off the excess solution, and place it under the ultra-clean workbench for 6 minutes to wait for it to dry in the shade; then add 0.15g of trimesoyl chloride 100ml of Isopar The G solution was poured into the interfacial polymerization, and placed under the ultra-clean workbench for 10 minutes to wait for it to dry in the shade, and then placed in an 80°C blast drying oven for 10 minutes to obtain a polyamide composite reverse osmosis membrane, which was designated as the M2 membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com