Fully automatic vacuum capper for square lithium ion battery and its capping method

A lithium-ion battery and vacuum sealing technology, which is applied to secondary batteries, battery pack components, non-aqueous electrolyte storage batteries, etc., can solve the problems of inability to accurately control the sealing height, poor pre-sealing vacuum degree, and battery thickness rebound, etc., to achieve Eliminate the deterioration of active materials and organic electrolytes, eliminate battery thickness rebound, and the effect of small capacity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

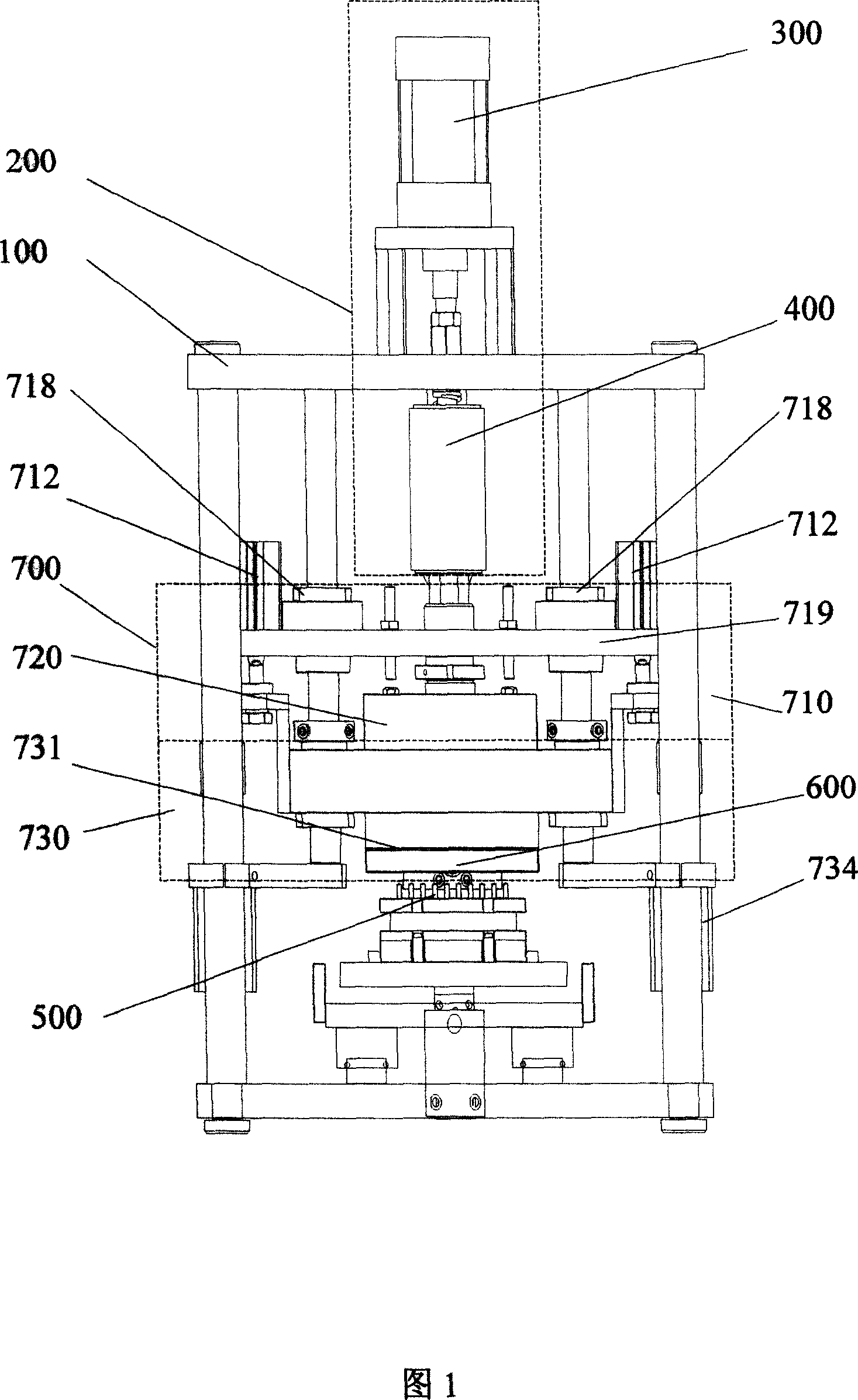

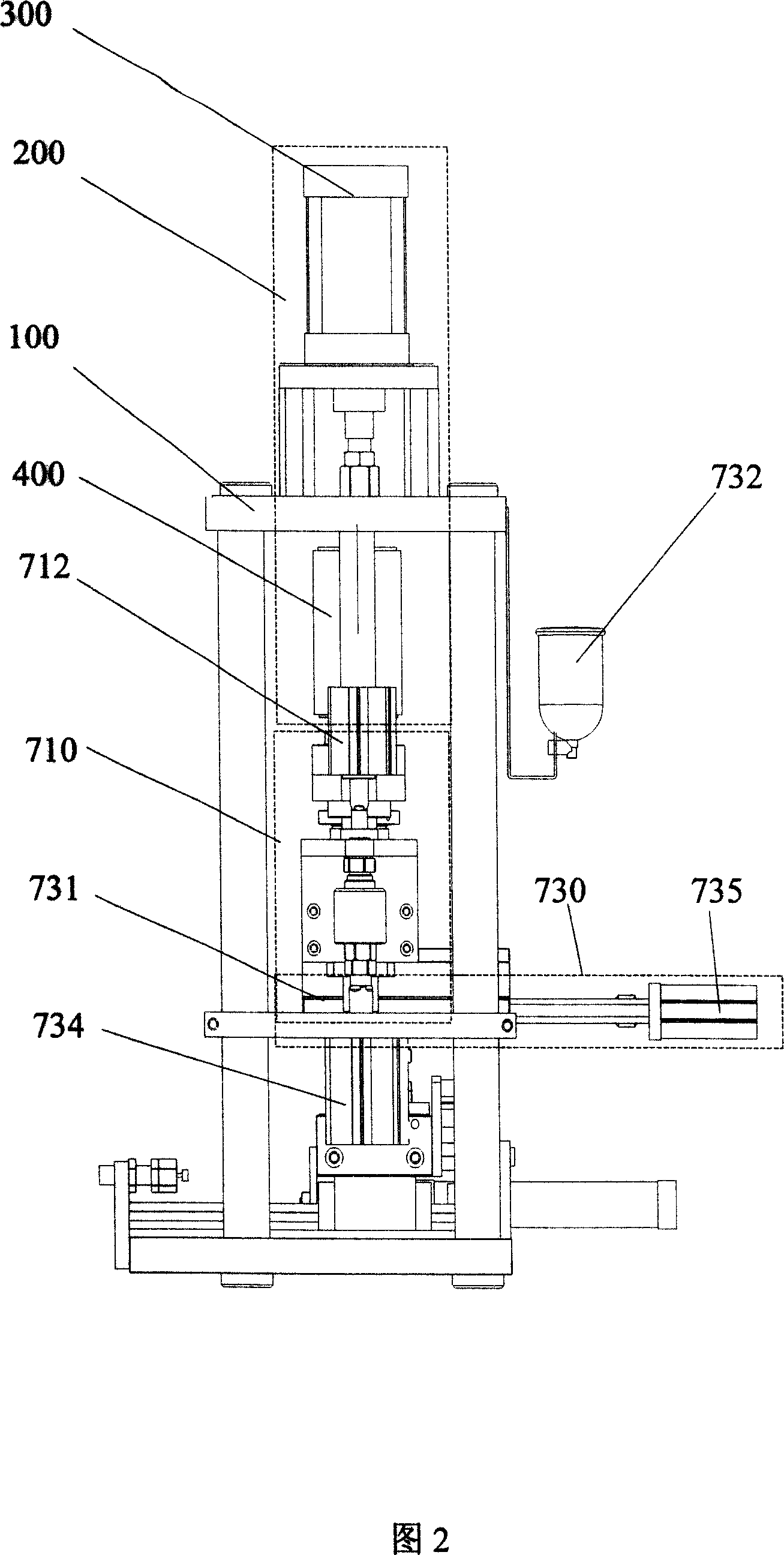

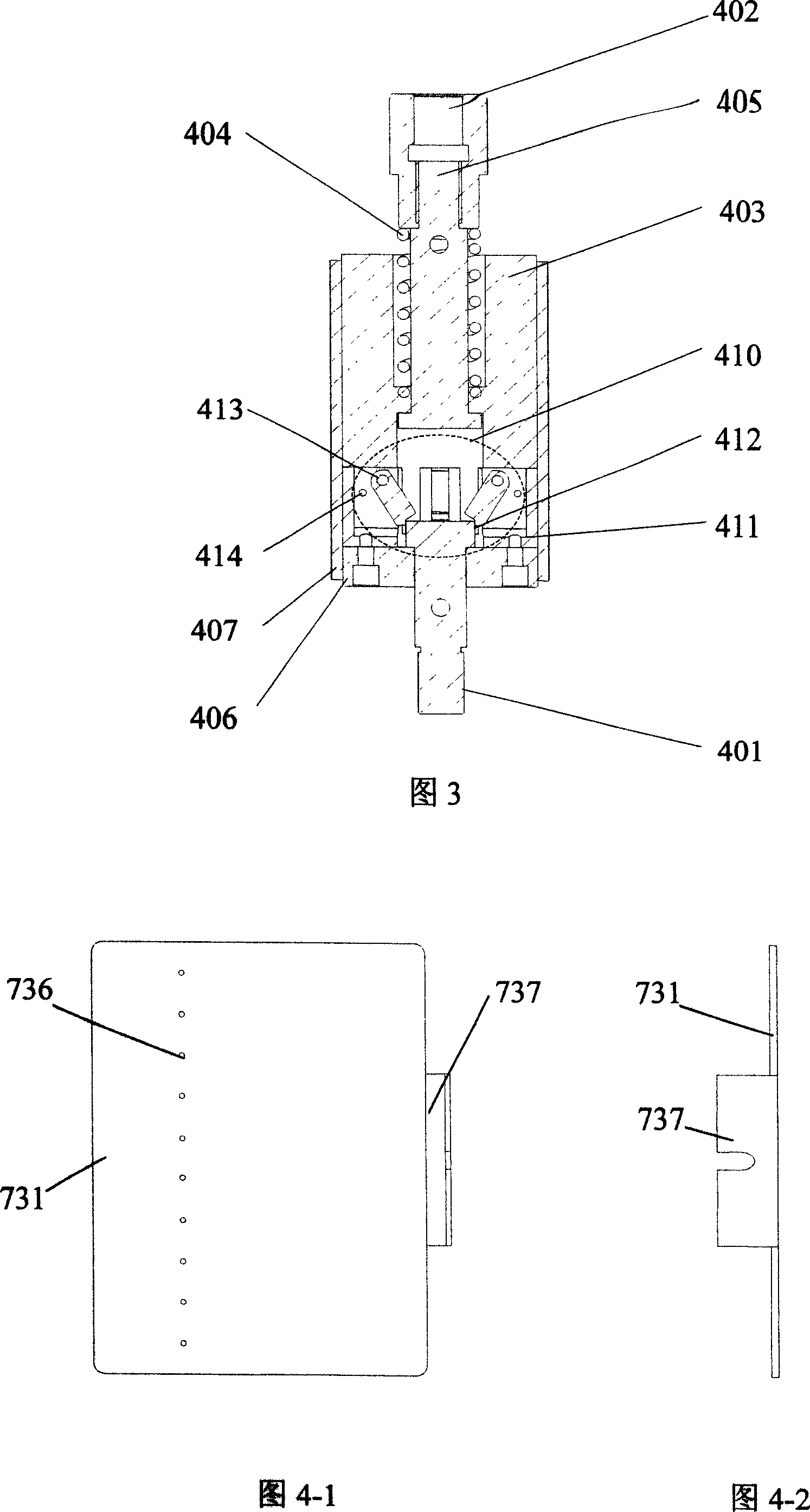

[0036]As shown in Fig. 1 and Fig. 2, the technical solution realized by the square lithium-ion battery automatic vacuum sealing machine of the present invention is: comprising frame 100, high-speed pressure unit 200 and battery clamp 500, described high-speed pressure unit 200 and battery A steel ball distributing device 700 is arranged between the clamps 500 ; the high-pressure power unit 200 includes a mechanical impact hammer 400 driven by a master cylinder 300 . As shown in Figures 1 and 3, the mechanical impact hammer body 400 includes a connecting piece 402, a push rod 405, an impact hammer body 403, a gram block unit 410 and a support that are arranged in a sleeve 407 and connected to the master cylinder 300 in sequence. Rod 401, the push rod 405 is connected to the inner hole boss of the impact hammer body 403 through the shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com