Oyster polysaccharide, preparing method and its application in preparing cosmetics

A technology of oyster polysaccharide and cosmetics, applied in oyster polysaccharide and preparation and its application field in the preparation of cosmetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

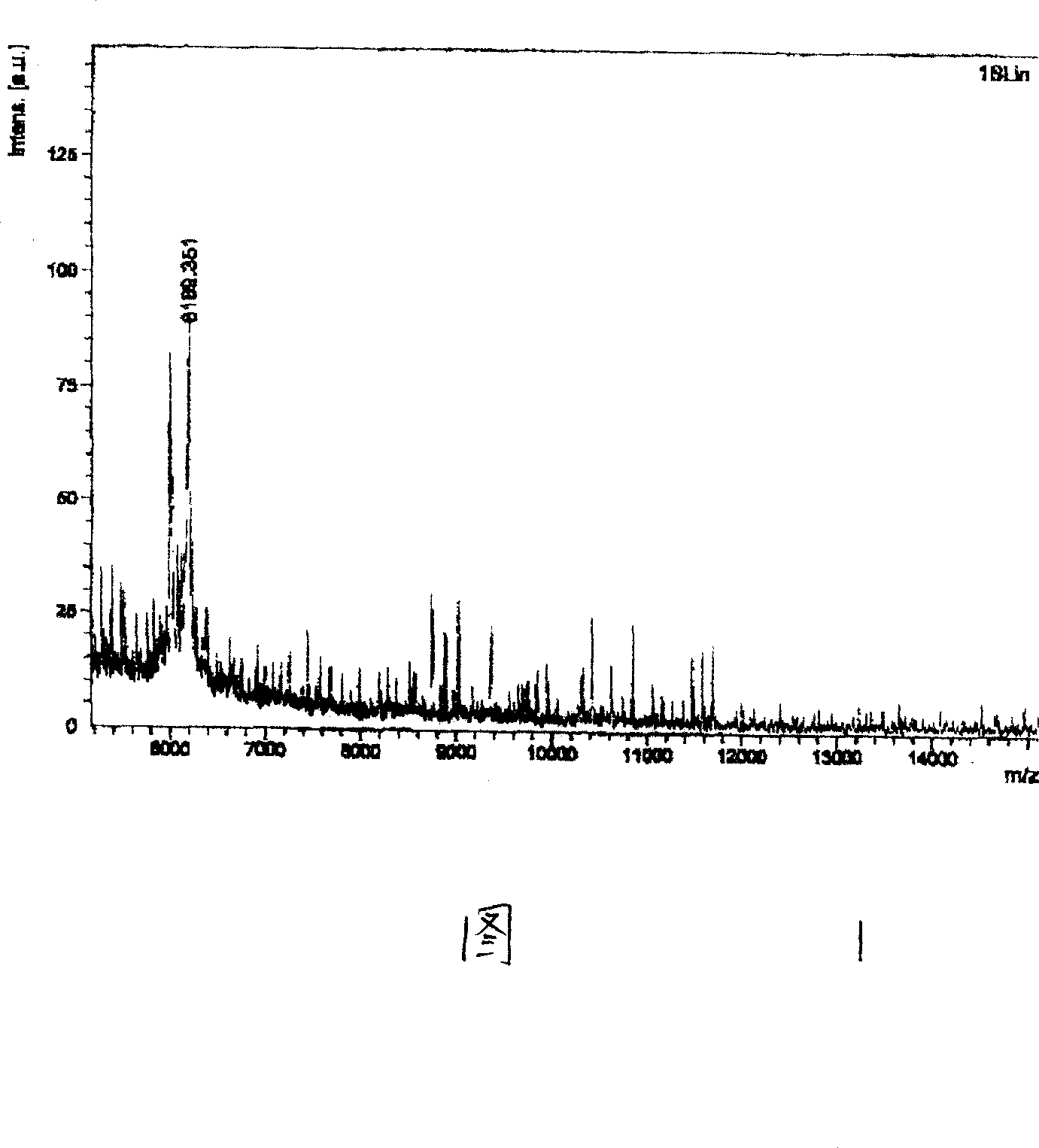

Image

Examples

Embodiment 1

[0020] a. Take Dalian Bay oysters or Pacific oysters, and wash the oysters with 0-10°C water;

[0021] b. use a high-pressure container, boil oysters with water at a pressure of 0.3MPa and a temperature of 70°C for 20 minutes, the weight ratio of water to oysters is 1.5 to 3: 1, filter and collect the supernatant;

[0022] c. Centrifuge to remove the precipitate, adjust the supernatant to pH 5 with 60% acetic acid, acidify for 1 hour, and use a membrane separator to intercept substances with a molecular weight below 30,000 Da;

[0023] d. Use NaOH to adjust the pH of the filtrate above 30000Da to 6, centrifuge to remove the precipitate, and take the supernatant to dialyze in distilled water to remove salt;

[0024] e. Pass through a Sephadex G-100 molecular sieve chromatography column to collect OD 280nm Absorption peak, dialysis to desalinate and then freeze-drying to obtain oyster polysaccharide.

[0025] Oyster polysaccharides were detected by enzymatic hydrolysis or enzy...

Embodiment 2

[0027] a. Take Dalian Bay oysters or Pacific oysters, and wash the oysters with 0-10°C water;

[0028] b. Use a high-pressure container to cook oysters with water at a pressure of 0.5 MPa and a temperature of 80° C. for 30 minutes. The weight ratio of water to oysters is 1.5 to 3: 1, filter and collect the supernatant;

[0029] c. Centrifuge to remove the precipitate, adjust the supernatant to pH 6 with 70% acetic acid, acidify for 3 hours, and use a membrane separator to intercept substances with a molecular weight below 30000Da;

[0030] d. Use NaOH to adjust the pH of the filtrate above 30000Da to 8, centrifuge to remove the precipitate, and take the supernatant to dialyze in distilled water to remove salt;

[0031] e. Pass through a Sephadex G-100 molecular sieve chromatography column to collect OD 280nm Absorption peak, dialysis to desalinate and then freeze-drying to obtain oyster polysaccharide.

[0032] Oyster polysaccharides were detected by enzymatic hydrolysis or ...

Embodiment 3

[0034] a. Take Dalian Bay oysters or Pacific oysters, and wash the oysters with 0-10°C water;

[0035] b. Use a high-pressure container to boil oysters at 0.4MPa pressure and 75°C for 45 minutes. The weight ratio of water to oysters is 1.5-3:1, filter and collect the supernatant;

[0036] c. Centrifuge to remove the precipitate, adjust the supernatant to pH 6 with 70% acetic acid, acidify for 2 hours, and use a membrane separator to intercept substances with a molecular weight below 30000Da;

[0037] d. Use NaOH to adjust the pH of the filtrate above 30000Da to 7, centrifuge to remove the precipitate, and take the supernatant to dialyze in distilled water to remove salt;

[0038] e. Pass through a Sephadex G-100 molecular sieve chromatography column to collect OD 280nm Absorption peak, dialysis to desalinate and then freeze-drying to obtain oyster polysaccharide.

[0039] Oyster polysaccharides were detected by enzymatic hydrolysis or enzymatic hydrolysis and nuclear magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com