Highly effective liquid phase chromatogram analyzing method of N-phenyl maleimide

A high-performance liquid chromatography, maleimide technology, applied in the direction of analysis of materials, material separation, measurement devices, etc., to achieve reliable analysis methods and simple quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the selection of chromatographic conditions

[0033] 1.1 Selection of mobile phase

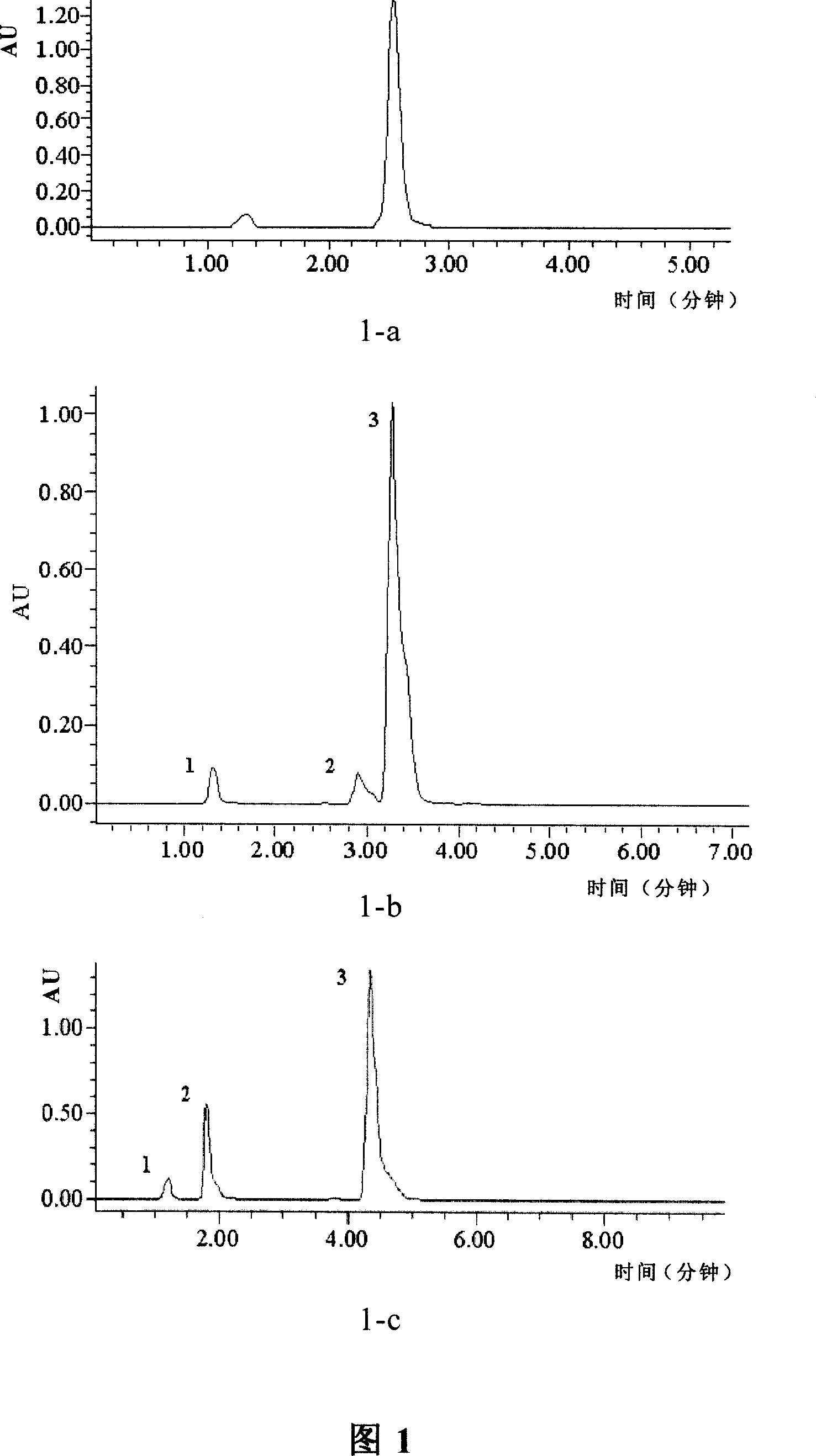

[0034] The mobile phase compositions with different volume ratios were compared, and the acetonitrile ratio was tested from high to low. The results showed that: when the acetonitrile ratio> 75%, the separation of the two impurity peaks is not good, and when the acetonitrile ratio> 80%, the two impurity peaks are difficult to separate , when the volume ratio of acetonitrile and water is 40:60, each component can achieve baseline separation, as shown in Figure 1.

[0035] 1.2 Selection of detection wavelength

[0036] Use a diode array detector to scan continuously at 200-400nm. It can be seen that N-PMI has a maximum absorption at 217nm, while aniline has a maximum absorption at 250nm, and maleic anhydride has a maximum absorption at 210nm. Taking into account the sensitivity of each component, select the detection The wavelength is 217nm.

[0037] 1.3 Sample concentrat...

Embodiment 2

[0039] Embodiment 2: the preparation of standard solution and sample solution

[0040] Accurately weigh 100.0 mg of N-PMI reference substance, put it in a 100 ml volumetric flask, dissolve it with 10 ml of acetonitrile, then dilute to the mark with mobile phase, shake well, and obtain a standard stock solution with a concentration of 1.0 mg / ml, and use it gradually diluted to the desired concentration.

[0041] Accurately weigh 50.0mg of aniline and maleic anhydride reference substances respectively, place them in a 100ml volumetric flask, dissolve them with 10ml of acetonitrile, then dilute to the mark with mobile phase, shake well, and obtain a standard stock solution with a concentration of 0.5mg / ml. When used, serially dilute to obtain the required concentration.

Embodiment 3

[0042] Embodiment 3: the making of standard curve

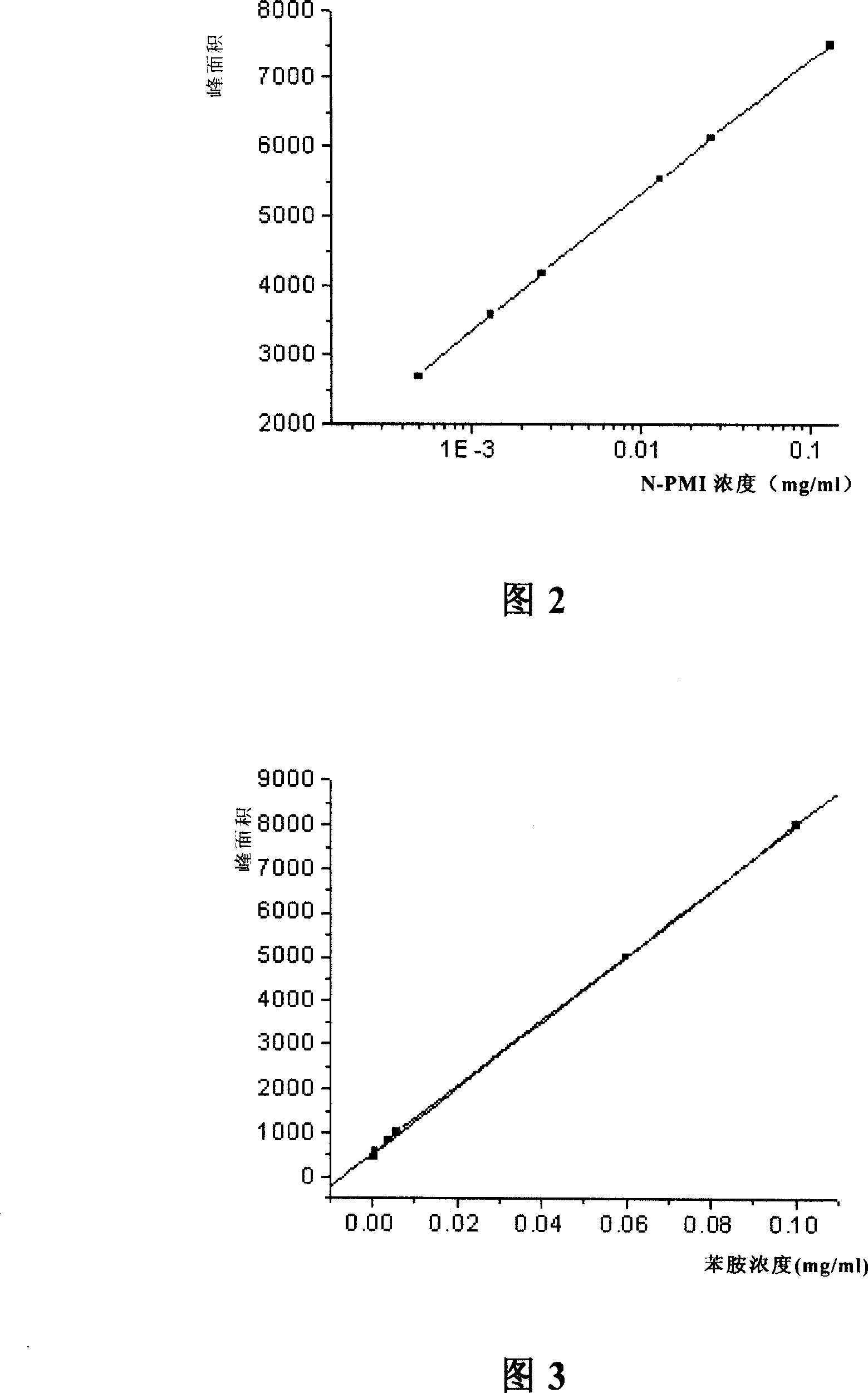

[0043] When the concentrations of aniline and maleic anhydride are 0.0005-0.1mg / ml and 0.0075-0.5mg / ml respectively, inject 5 μl of the sample, and plot the peak area against the concentration, as shown in Figure 3 and Figure 4. The regression equation is:

[0044] A 苯胺(area) =508+7492.5C 苯胺 , r=0.99988

[0045] A 马来酐(area) =50.69+7494.8C 马来酐 , r=0.99987

[0046] When the concentration of N-phenylmaleimide is 0.0001-0.5 mg / ml, inject 5 μl, plot the peak area against the concentration, see Figure 2, and the regression equation is:

[0047] A N-PMI(area) =992.7+1967.2logC N-PMI , r=0.99993

[0048] When the signal-to-noise ratio S / N=3, the lowest detection limits of N-PMI, aniline and maleic anhydride were 0.00005 mg / ml, 0.00025 mg / ml and 0.003 mg / ml, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com