On-line modified producing method for engineering plastics

A technology for engineering plastics and production methods, applied in chemical instruments and methods, filter screens, grids, etc., can solve the problems of product physical and chemical performance index damage, insurmountable batch differences, high energy consumption and production costs, and achieve product quality. Uniform and reliable, stable and reliable production operation, excellent and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

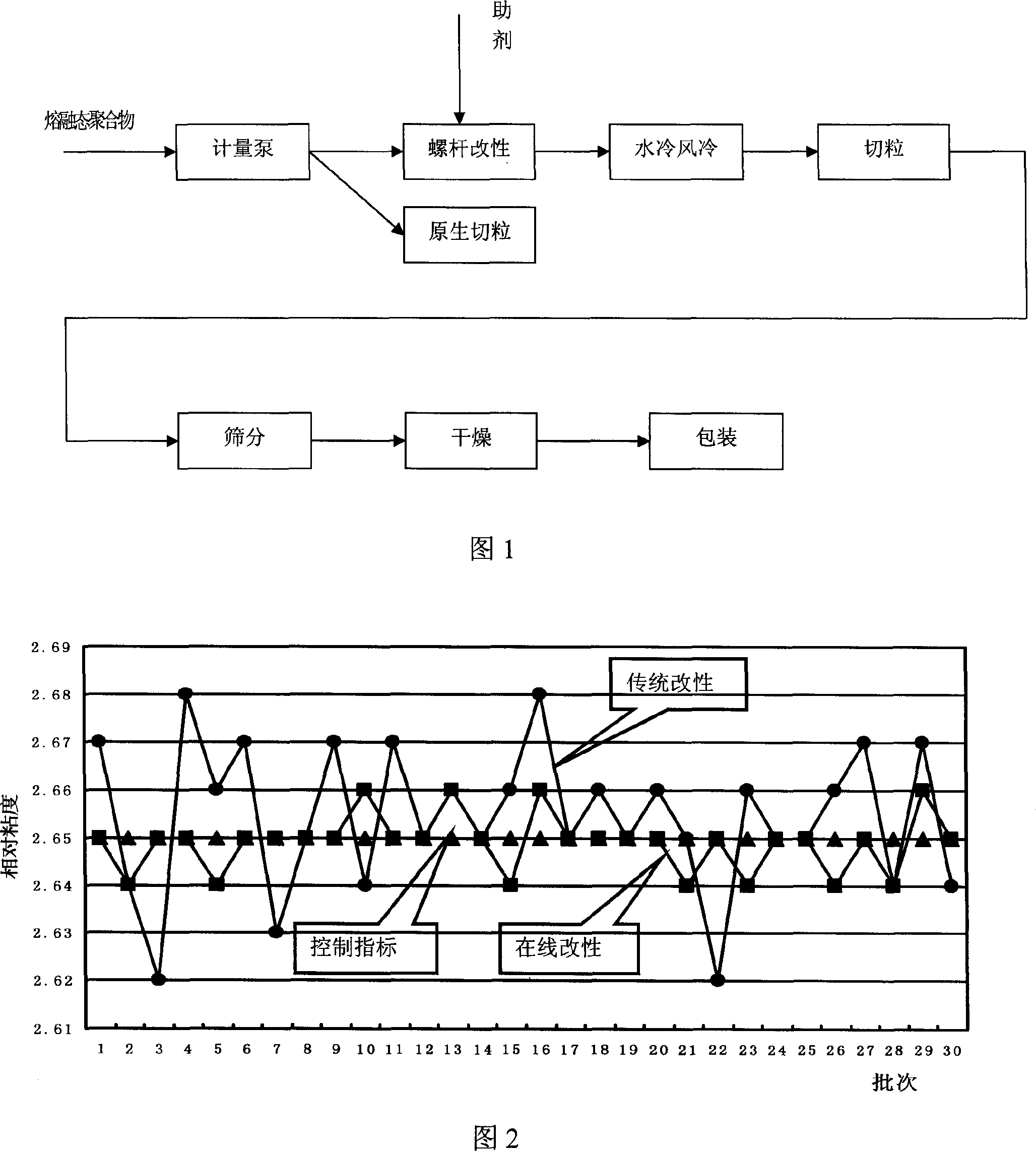

[0025] On-line modification production method of engineering plastics, the molten polymer with a certain molecular weight obtained through continuous polymerization is directly sent to the twin-screw extruder online, and an appropriate amount of additives are added according to product requirements, and it is uniformly mixed through the twin-screw extruder extrude. The extruded strips are water-cooled and air-cooled, and then enter the strand granulator for pelletizing, and then sieve through the vibrating screen to remove unqualified slices. After being cooled and dried by the fluidized bed, the slices are collected into the packaging silo, and enter the automatic packaging line for packaging.

[0026] Take the online modification of nylon 66 as an example: the engineering plastic is nylon 66, the auxiliary agent is glass fiber, the amount of glass fiber added is 30%wt of the total material, and the technical parameters of the molten polymer entering the twin-screw extruder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com