Influent polymer cement concrete pavement structure on stabilization base course and contracture method

A cement concrete and pavement structure technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of non-continuous paving and difficult implementation, and achieve reduced brittleness, good crack resistance, and good water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An example below:

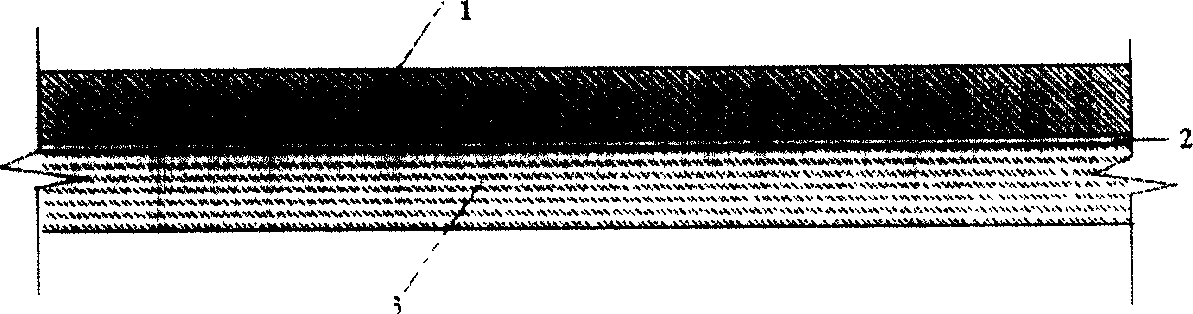

[0031] Its structure is: stable base 3, adhesive layer 2, inflow polymer cement concrete surface layer 1, the stable base 3 has an adhesive layer 2 on the surface, and an inflow polymer cement concrete surface on the adhesive layer 2 Layer 1.

[0032]First, clean the previously formed cement-stabilized gravel base, and then manually spread polymer cement mortar on it to form a bonding layer. The weight ratio of the bonding layer is - polymer (styrene butadiene rubber emulsion ): Filler (Ordinary Portland Cement PO 42.5): Water: Auxiliary (silicone oil defoamer) = 1:3:1:0.01, add water to dilute the bonding layer material to facilitate construction; after 1 hour, use cement The concrete mixer prepares porous cement concrete with a certain dry consistency and is suitable for the self-leveling and self-vibration process of asphalt paver. The weight ratio is - ordinary portland cement PO 42.5: crushed stone (single grade, Diameter 5-10mm): sand: water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com