Process of producing active protein and oil with maggot and earth worm

An active protein and earthworm technology, applied in the application, animal feed molding or processing, animal feed and other directions, can solve the problem of unable to produce degreasing active protein and oil, etc., to retain nutrients, improve digestion and absorption utilization, and production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

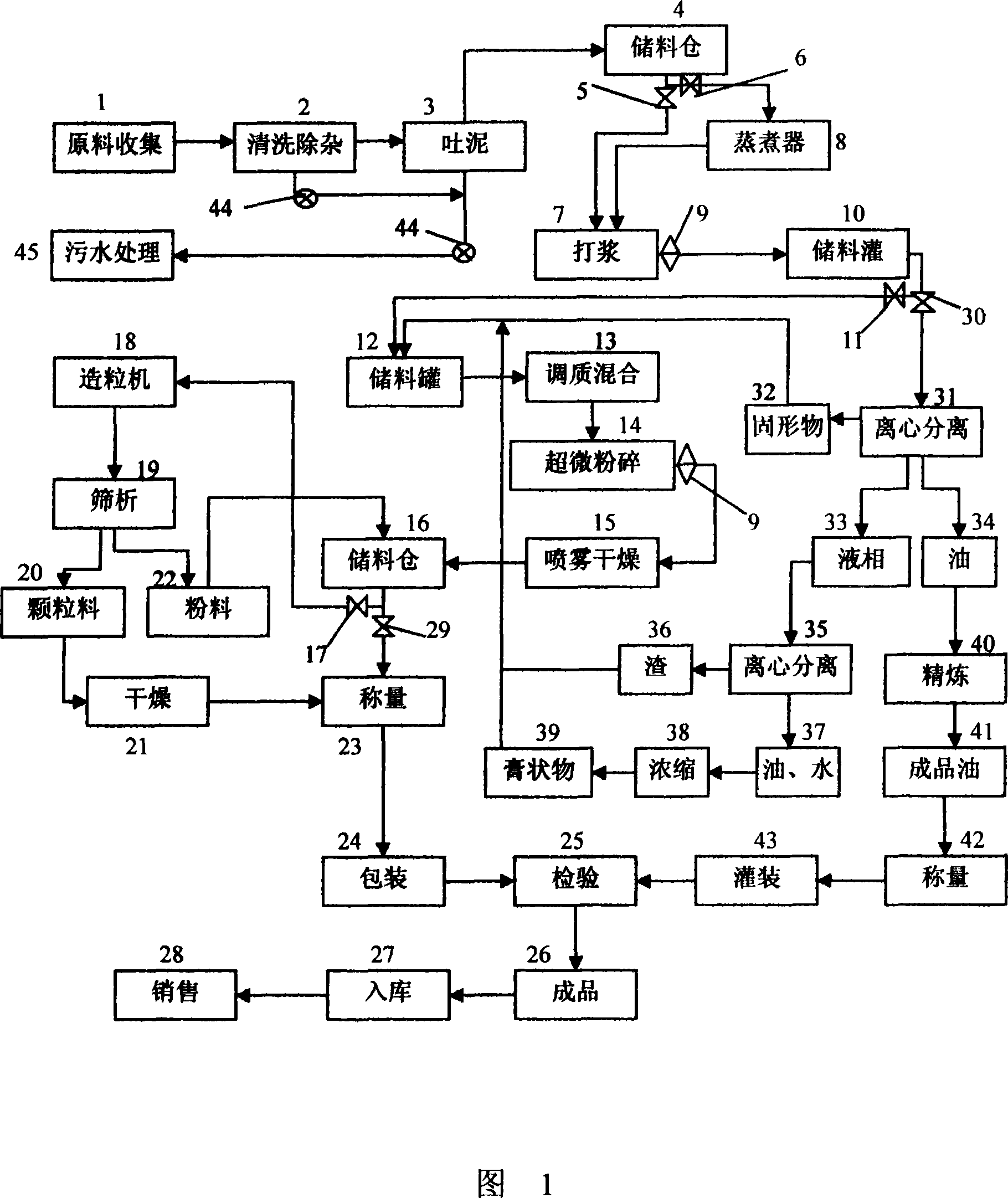

[0015] Embodiment: see the technological process shown in Fig. 1. The fly maggots or earthworms collected from raw materials (1) are cleaned to remove impurities (2), quicklime is added to the mud discharge device (3), and the pH value is adjusted to 10-11. After staying in the mud device for 10 to 15 minutes, it is sent into the storage bin (4) by a screw conveyor for subsequent use. The valve (5) and the valve (6) at the discharge port of the storage bin (4) are respectively used to control the opening or closing of the beater (7) and the digester (8) when raw materials are conveyed. The cooker (8) adopts a high-temperature or isoelectric point cooking method to keep the steam temperature at 80° C. to 95° C. and cook for 8 to 15 minutes. The digester can adopt a stainless steel cylindrical multi-layer automatic feeding, discharging and temperature control device, and can also be replaced by the multi-layer digester required for manufacturing aquatic pellet feed in the exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com