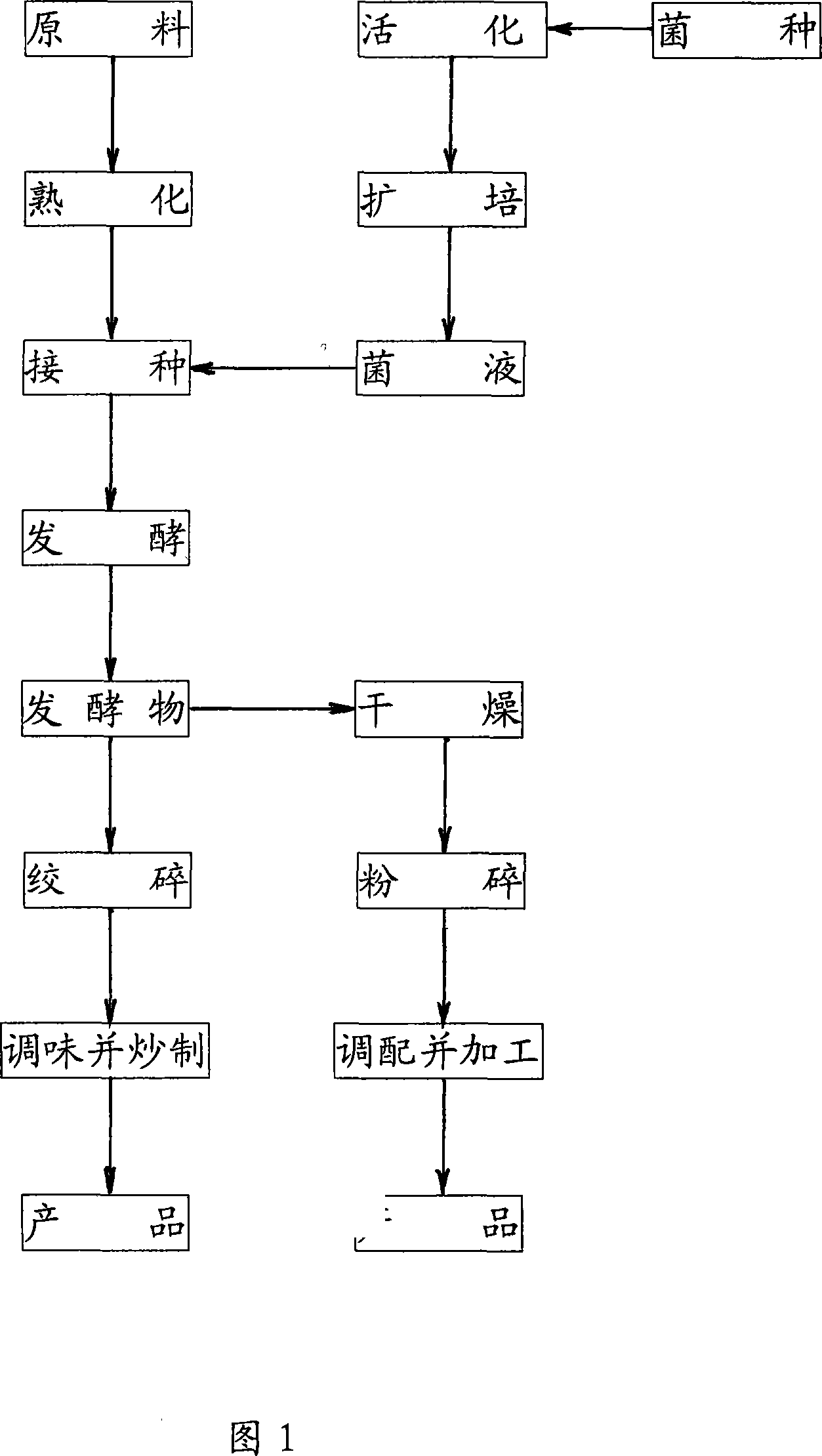

Making process of fermented plant fiber and protein food

A plant fiber and fermented food technology, applied in fermented food, plant fibrous protein fermented food, and food fields, can solve the problem of not finding ideal answers to technical problems, not finding patent documents and related materials, and not having nutritional and health value and other issues, to achieve good social and economic benefits, effective removal of beany smell, improvement of nutrition and edible processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0079] Carry out by specific implementation mode one, just:

[0080] Operation steps (1). The adjusted water content of ② is 65%;

[0081] The ripening time of operation step (2) is 25 minutes;

[0082] Operation step (3). ② The strain activation temperature is 29°C;

[0083] Adjust the pH value of the bacterial liquid to 3 in the preparation of the bacterial liquid in the operation step (3).④;

[0084] Operation step (3). ⑤, the inoculum amount of the bacterial liquid is 6% of the raw material to be used when inoculating in the inoculation of the raw material to be used;

[0085] Operation step (4), fermentation: after inoculation of raw materials, ferment and cultivate for 30 hours at a temperature of 20°C and a relative humidity of 75% to obtain a fermented product;

[0086] Operation steps (5). ②.A. Drying: drying the fermented product at 80°C until the water content is 11% to obtain the dried product.

specific Embodiment approach 3

[0087] Carry out by specific implementation mode one, just:

[0088] Operation steps (1). The adjusted water content of ② is 70%;

[0089] The ripening time of operation step (2) is 30 minutes;

[0090] Operation step (3). ② The strain activation temperature is 30°C;

[0091] Adjust the pH value of the bacterial liquid to 4 in the preparation of the bacterial liquid in the operation step (3).④;

[0092] Operation step (3). ⑤, the inoculum amount of the bacterial liquid is 7% of the raw material to be used when inoculating in the inoculation of the raw material to be used;

[0093] Operation step (4), fermentation: after inoculation of the raw material, ferment and cultivate for 40 hours at a temperature of 25°C and a relative humidity of 80% to obtain a fermented product;

[0094] Operation steps (5). ②.A. Drying: drying the fermented product at 85°C until the water content is 12% to obtain the dried product.

specific Embodiment approach 4

[0095] Carry out by specific implementation mode one, just:

[0096] Operation steps (1). The adjusted water content of ② is 75%;

[0097] The ripening time of operation step (2) is 35 minutes;

[0098] Operation step (3). ② The strain activation temperature is 28°C;

[0099] Adjust the pH value of the bacterial liquid to 5 in the preparation of the bacterial liquid in the operation step (3).④;

[0100] Operation step (3). ⑤, the inoculum amount of the bacterial liquid is 8% of the raw material to be used when inoculating in the inoculation of the raw material to be used;

[0101] Operation step (4), fermentation: after inoculation of the raw material, ferment and cultivate for 50 hours at a temperature of 30° C. and a relative humidity of 85% to obtain a fermented product;

[0102] Operation steps (5). ②.A. Drying: drying the fermented product at 75°C until the moisture content is 13% to obtain the dried product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com