Fire-extinguishing multicomponent fine water fog additive and its prepn

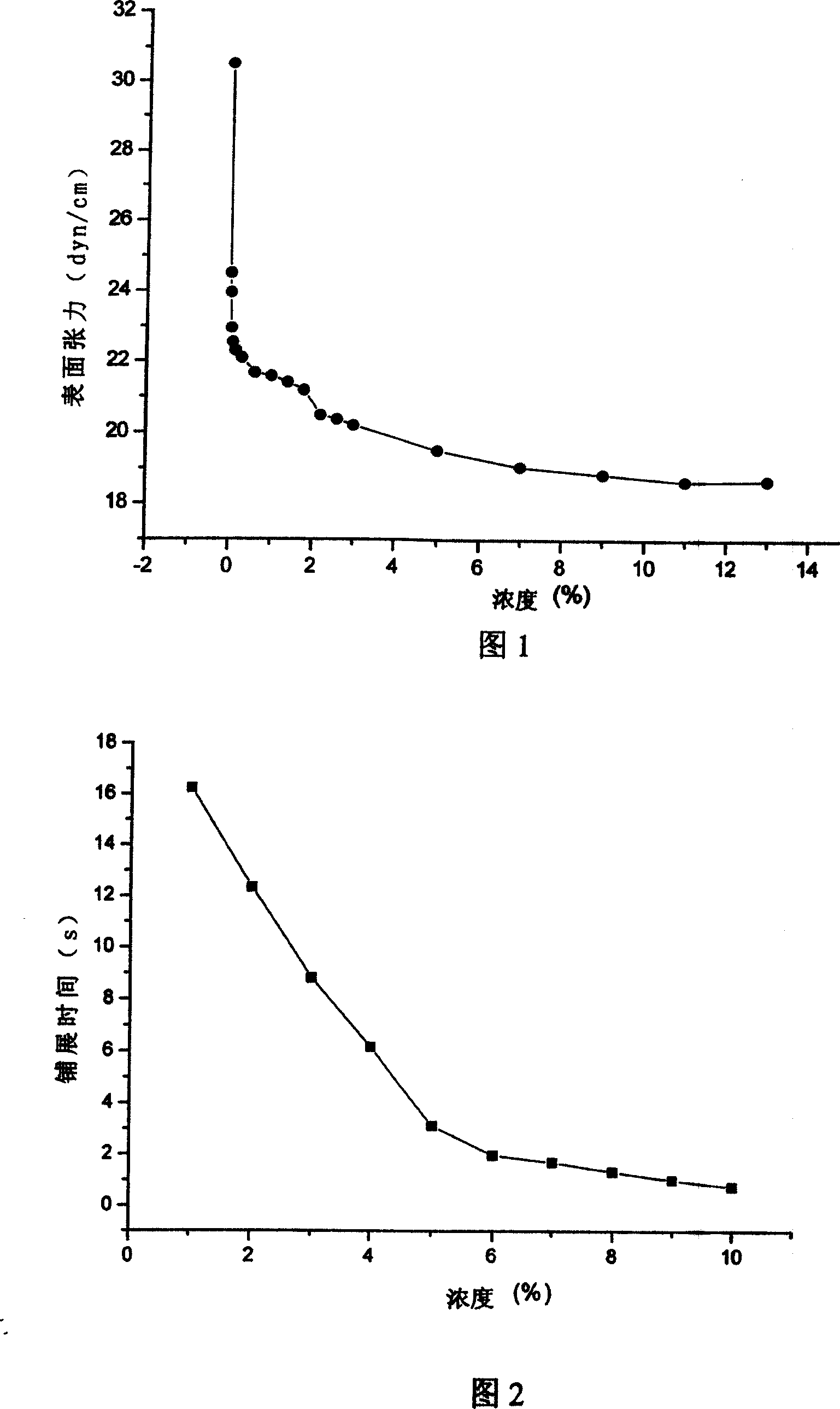

A multi-component, fine water mist technology, applied in the direction of fire prevention equipment, etc., can solve the problems of pollution, corrosion, oxygen insulation effect and low fire extinguishing efficiency, and achieve the effect of enhancing fire extinguishing efficiency, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Novel multi-component water mist fire extinguishing additive of the present invention adopts Table 2 formula:

[0049] Table 2

[0050] components

[0051] The specific preparation steps of the formula are:

[0052] 1. Add 4% fluorosurfactant to the alcohols with 45% total mass of the solution, stir for 5-10 minutes and dissolve, the solution turns yellow.

[0053] 2. Slowly add octylphenol polyoxyethylene ether accounting for 12% of the total mass of the solution and N,N-dimethylformamide accounting for 0.5% of the total mass of the solution to the above solution in sequence, and stir for 2 to 5 minutes to dissolve into Uniform phase.

[0054] 3. Continue to add water accounting for 33% of the total mass of the solution. After stirring for 1 minute, the solution becomes a homogeneous phase, and the yellow color of the solution becomes lighter.

[0055] 4. In the above-mentioned light yellow solution, add successively account for 5% of the total mass of anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com