Process of comprehensively utilizing high temperature nickel smelting slag

A technology of molten slag and high temperature, which is applied in the field of comprehensive utilization of high-temperature nickel smelting molten slag, which can solve the problems of high price, high consumption, and inability to make colored glass-ceramics, etc., and achieve high value-added utilization and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

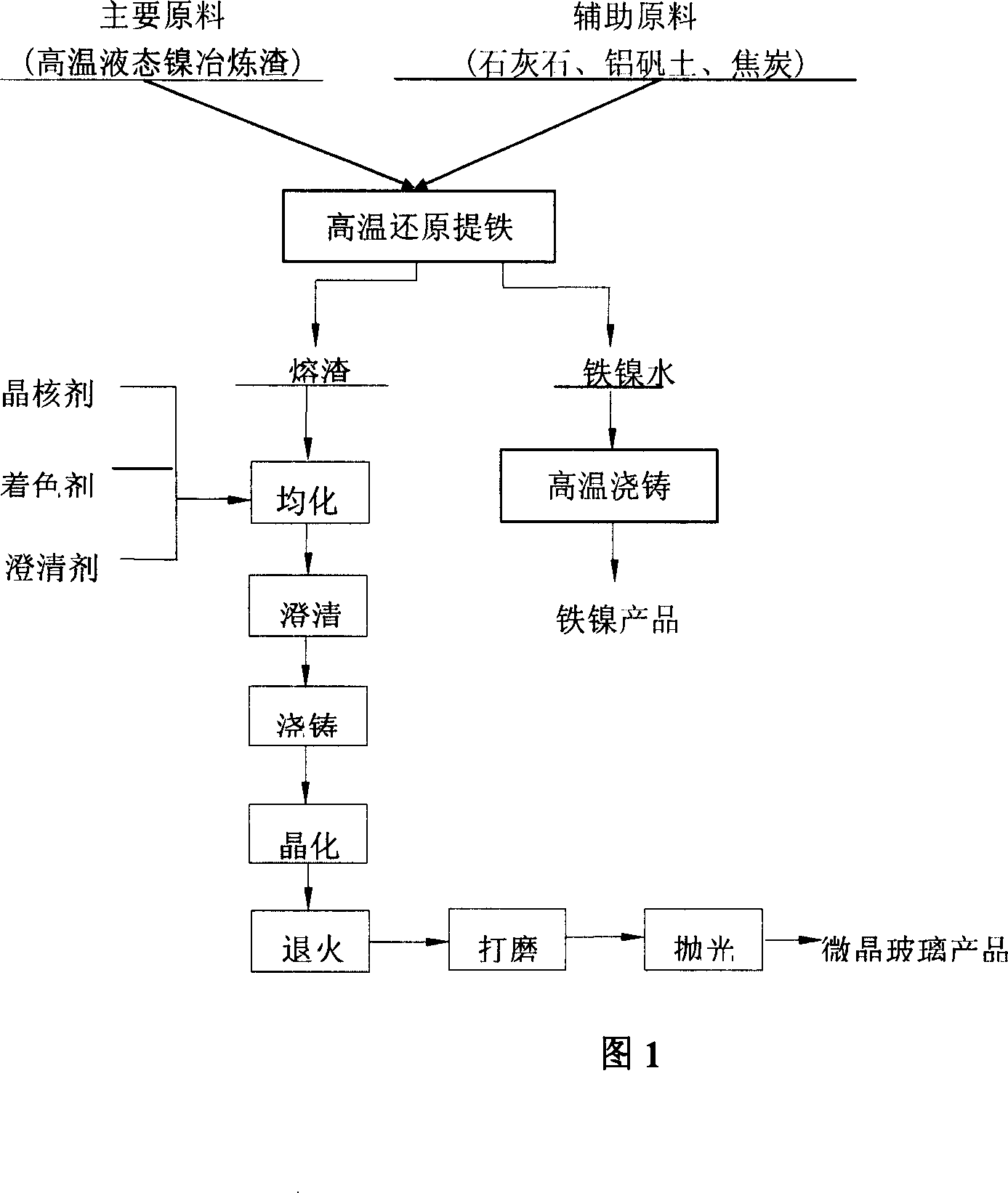

Method used

Image

Examples

Embodiment 1

[0024] The raw materials are proportioned by weight: 74.74% of molten nickel smelting slag, 18.99% of limestone, and 6.26% of coke; the molten slag after iron removal is discharged into the glass clarification and homogenization device with 3% of the total amount of NaNO added to the glass melt 3 As a clarifying agent, 2% Cr 2 O 3 As a nucleating agent.

[0025] The weight percentages of the main chemical components of the above-mentioned molten nickel smelting slag are: Ni 0.23%, Cu 0.16%, Co 0.03%, FeO 50.25%, CaO 3.37%, MgO 8.86%, SiO 2 34.61%, A1 2 O 3 2.26%. The above-mentioned limestone, CaO content is 50%, Fe 2 O 3 The content is 0.10%. The above sodium nitrate, NaNO 3 The content is 98.5%, Fe 2 O 3 The content is 0.005%.

[0026] Discharge the molten nickel smelting slag into the cupola of the smelting reduction unit and add batch materials and reducing agent for slag-iron separation treatment. Keep the temperature at 1500°C for 120 minutes; desulfurize the reduced iron, n...

Embodiment 2

[0029] The raw materials are proportioned by weight: 68.29% of molten nickel smelting slag, 26% of limestone, and 5.71% of coke; the molten slag after iron removal is discharged into the glass clarification and homogenization device with 3% of the total amount of NaNO added to the glass melt 3 As a clarifying agent, 2% Cr 2 O 3 As a nucleating agent.

[0030] The weight percentages of the main chemical components of the above-mentioned molten nickel smelting slag are: Ni 0.23%, Cu 0.16%, Co 0.03%, FeO 50.25%, CaO 3.37%, MgO 8.86%, SiO 2 34.61%, A1 2 O 3 2.26%. The above-mentioned limestone, CaO content is 50%, Fe 2 O 3 The content is 0.10%. The above sodium nitrate, NaNO 3 The content is 98.5%, Fe 2 O 3 The content is 0.005%.

[0031] Discharge the molten nickel smelting slag into the cupola of the smelting reduction unit and add batch materials and reducing agent for slag-iron separation treatment. Keep the temperature at 1500°C for 120 minutes; desulfurize the reduced iron, nickel...

Embodiment 3

[0034] The raw materials are proportioned by weight: molten nickel smelting slag 77.525%, limestone 16.19%, coke 6.29%; the molten slag after iron removal is discharged into the glass clarification and homogenization device with 3% NaNO added to the total glass melt 3 As a clarifying agent, 2% Cr 2 O 3 As a nucleating agent.

[0035] The weight percentages of the main chemical components of the above-mentioned molten nickel smelting slag are: Ni 0.30%, Cu0.116%, Co 0.019%, FeO 47.33%, CaO 4.13%, MgO 9.32%, SiO 2 34.69%, Al 2 O 3 3.15%, other 1.15%. The above limestone, CaO content is 50%, Fe 2 O 3 The content is 0.10%. The above sodium nitrate, NaNO 3 The content is 98.5%, Fe 2 O 3 The content is 0.005%.

[0036] Discharge the molten nickel smelting slag into the cupola of the smelting reduction unit and add batch materials and reducing agent for slag-iron separation treatment. Keep the temperature at 1500°C for 120 minutes; desulfurize the reduced iron, nickel, copper, and cobalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com