Antiplugging controllable displacement sheave dispensing valve

A volumetric, anti-clogging technology, applied in the direction of multi-way valves, valve devices, mixer accessories, etc., can solve the problems of contaminated materials, loss of adjustment function, insufficient hardness and rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

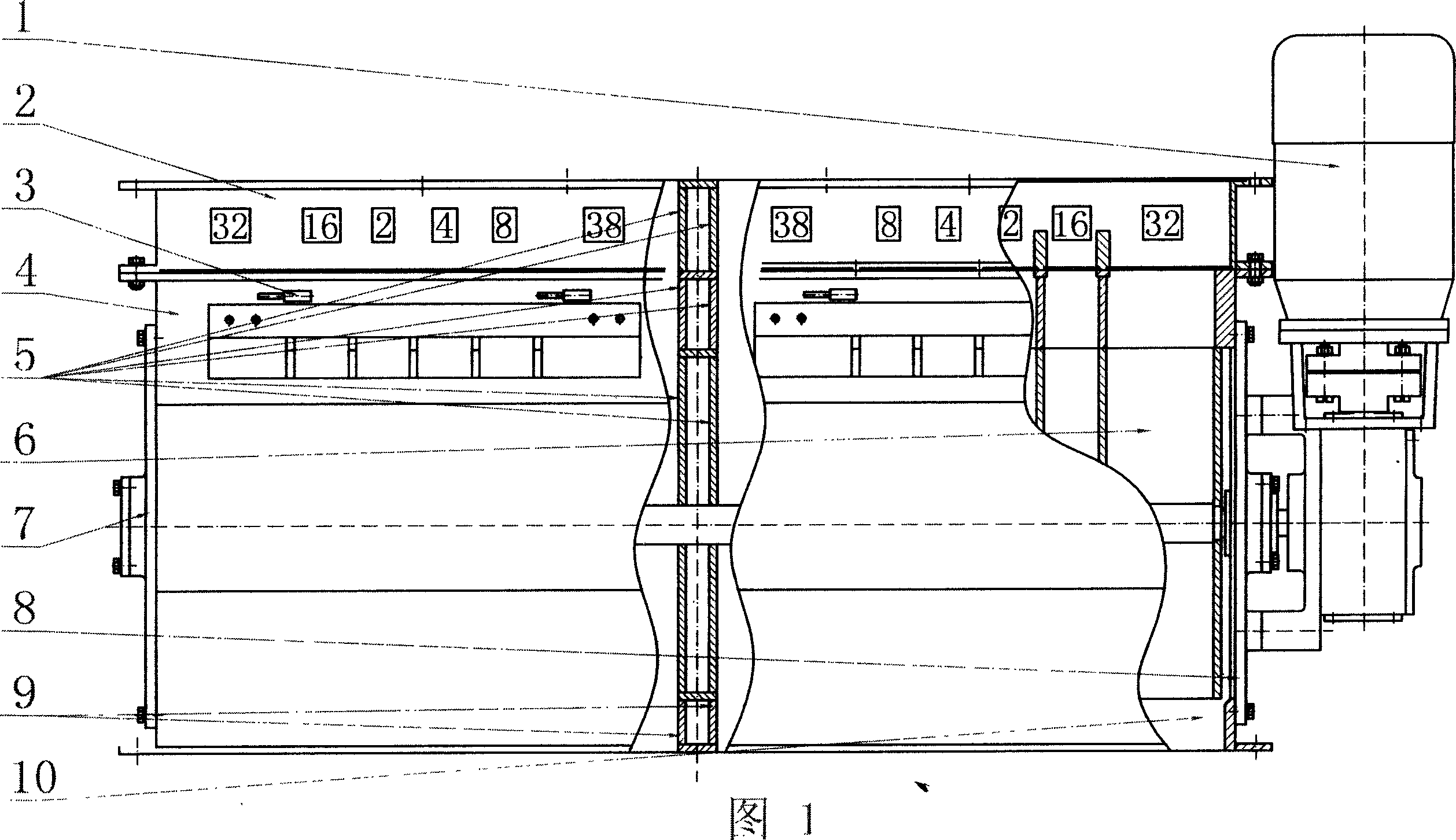

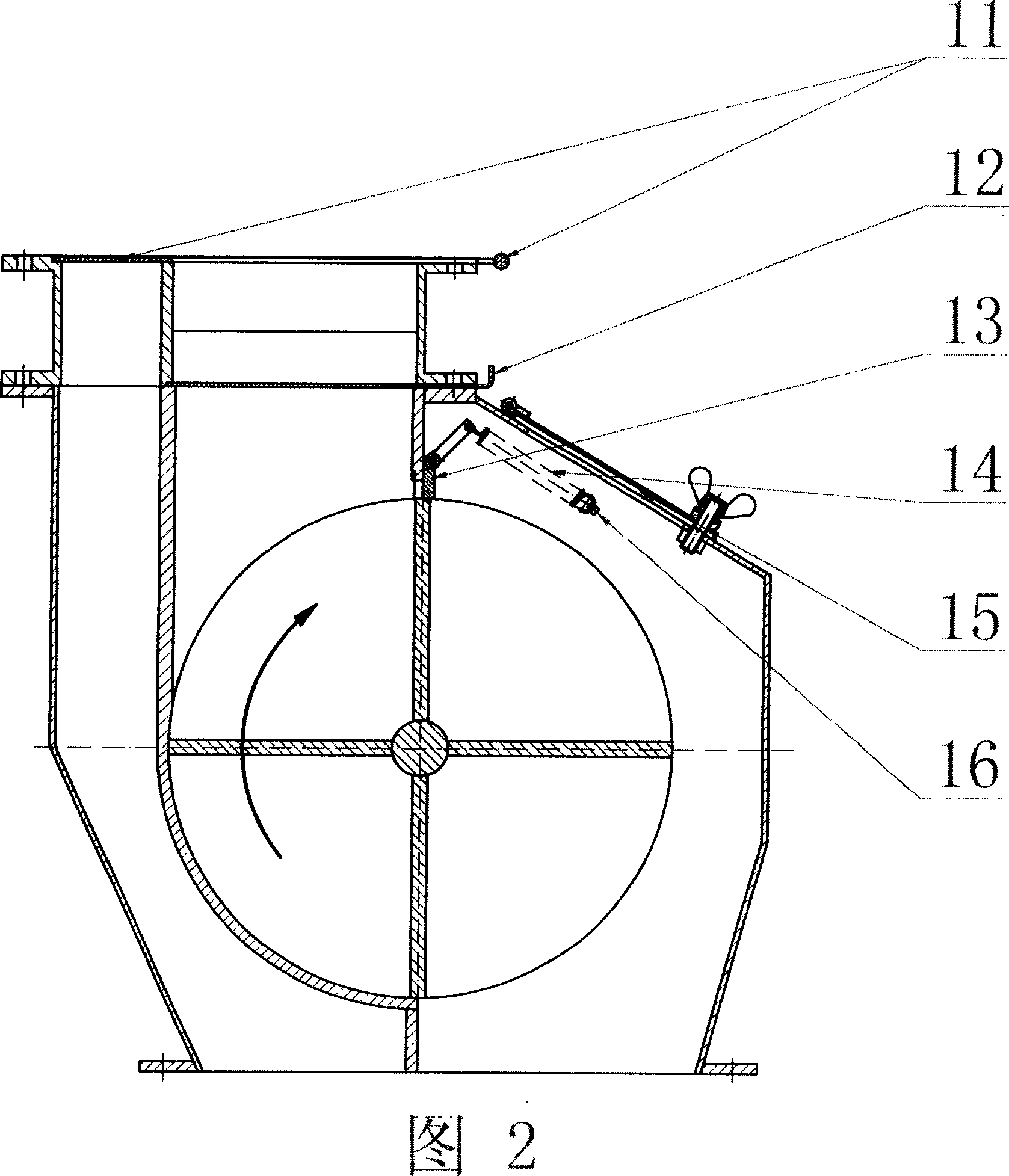

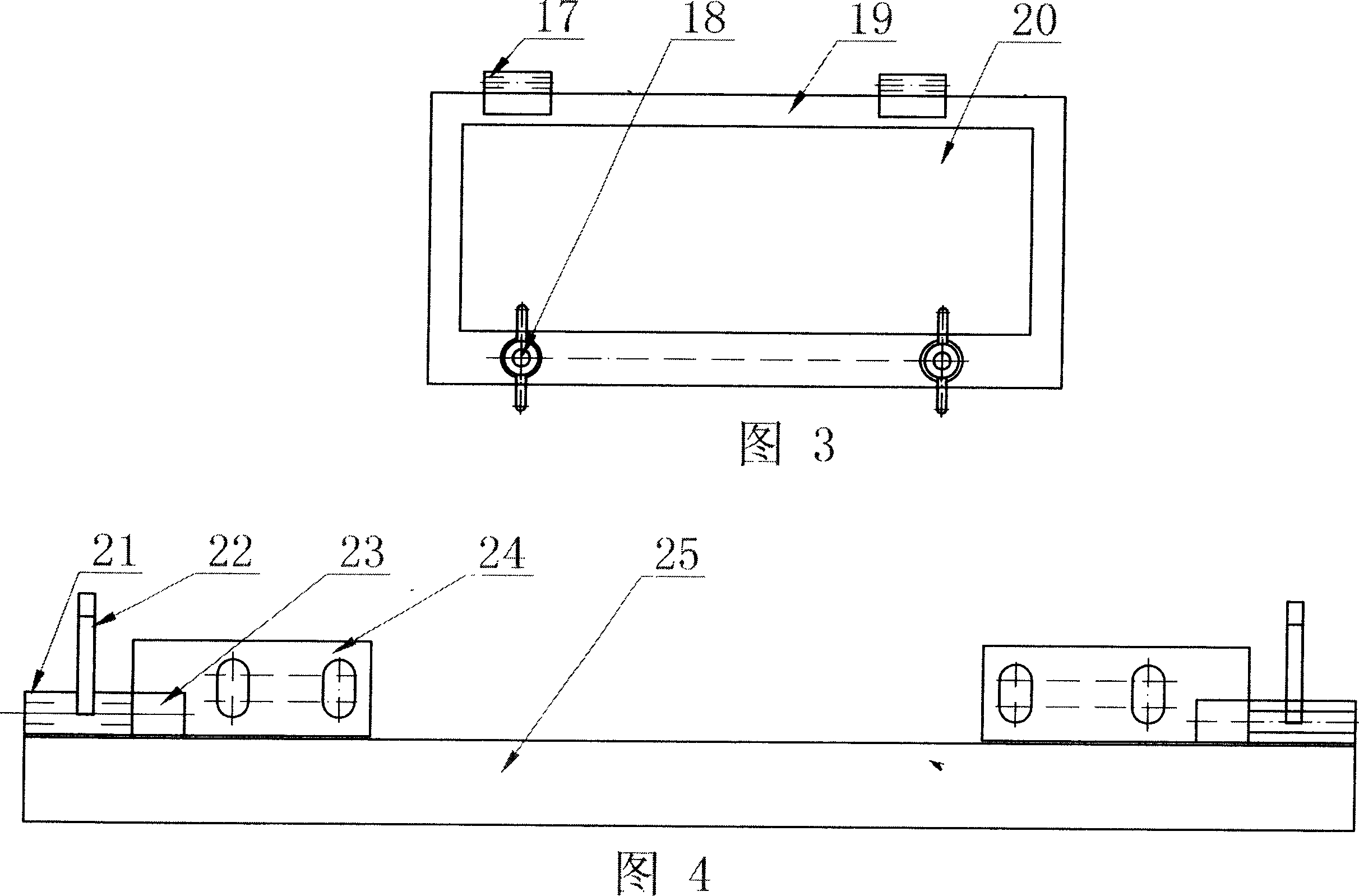

[0021]As shown in Fig. 1 and Fig. 2: the casing (4) of the present invention of 6 grooves of every storehouse of two working warehouses is a section that is the rectangular casing of scalene heptagonal type, and the upper end horizontal plane of casing (4) has A rectangular feed inlet is connected with a square barrel-shaped splitter box (2) with substantially the same inner hole size; there are two rectangular observation windows (15) made of plexiglass plates and steel window frames on the inclined plane at the upper end, The horizontal surface of the lower end is connected with two rectangular discharge ports (10) and the discharge pipe (not shown in the figure), and two strip-shaped elastic scrapers (13) are also installed near the upper end surface of the casing (4). ), the scraper (25) that can rotate on the fixed shaft is pressed tightly by the tension of two springs (14) hanging on the spring hanging plate (22) and the spring hook (16) welded on the casing (4). Stick i...

Embodiment 2

[0024] As shown in Figure 5, after the present invention uses 4 groove schemes instead, the grooves on the sheaves of each work chamber are reduced from 6 to 4 in the equipment structure, so the length of the whole sheave and the whole machine are equal to each chamber sheave. Except for the corresponding shortening, other structural dimensions, types of parts, shapes and sizes of parts and mutual relations etc. are all identical to Embodiment 1.

[0025] Also as shown in Figure 5, because the embodiment of the present invention 2 is obviously shortened in the equipment structure except that the length of the sheave of each warehouse is shortened, and the length of the whole machine is also shortened correspondingly, other structural dimensions, parts types, parts shape dimensions and interrelationships, etc. It is completely the same as Embodiment 1, so the working principle and functions of Embodiment 2 must also be the same as Embodiment 1. The reason why the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com