Filtering optical read-out micro beam temperature sensor

A temperature sensor and optical readout technology, applied in the field of sensing elements, can solve the problems of long thermal response time, unsatisfactory temperature resolution dynamic response performance, large bending stiffness, etc., to increase and shorten the area-to-volume ratio. Thermal response time, easy reception and handling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

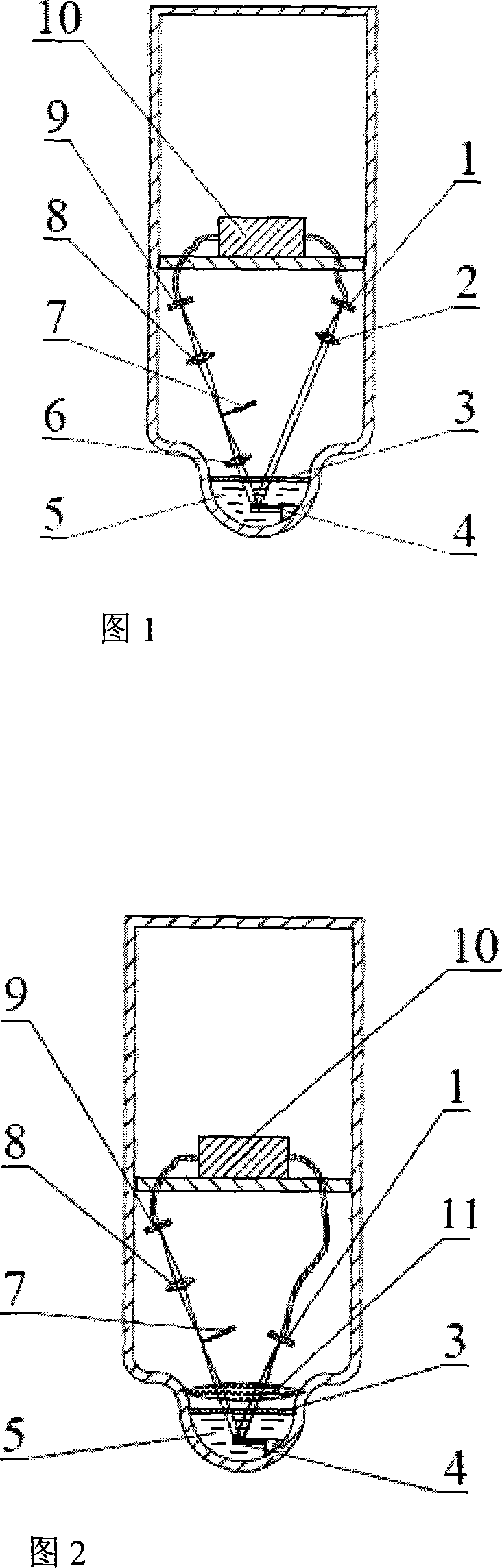

[0034] Referring to Fig. 1, the dual-material microbeam unit 4 is arranged in the temperature sensing head 5, and the point light source 1 is located at the incident side of the microbeam reflector, and is projected on the microbeam reflector;

[0035] On the reflection side of the micro-beam reflector, the linear boundary filter unit 7 is set on the converging spectrum plane of the reflected light from the micro-beam reflector, and the imaging lens 8 is positioned at the rear stage of the linear boundary filter unit 7, and the imaging lens 8 is arranged on the imaging lens 8. The photoelectric receiver 9 on the position is light intensity receiver, light intensity receiver.

[0036] As shown in Fig. 1, the temperature-sensing head 5 is composed of a heat-conducting shell and a closed chamber filled with a heat-conducting liquid. The top cover of the closed chamber is a light-transmitting window 3 that transmits visible light, and the double-material microbeam unit 4 is immerse...

Embodiment 2

[0042] Referring to FIG. 2 , in this embodiment, the same lens 11 is used for the collimation of the illuminating beam of the point light source 1 and the convergence of the reflected beam on the microbeam reflector, that is, the collimating lens and converging lens 11, which simplifies the mechanism.

Embodiment 3

[0044] Referring to Fig. 3, with respect to the above-mentioned embodiment 1 and embodiment 2, in this embodiment, the converging light of the point light source 1 is used as the illumination beam to directly irradiate on the micro-beam reflector, and the reflected beam formed after being reflected by the micro-beam reflector The focal point of the converging light spot is on the plane where the filtering unit 7 is located.

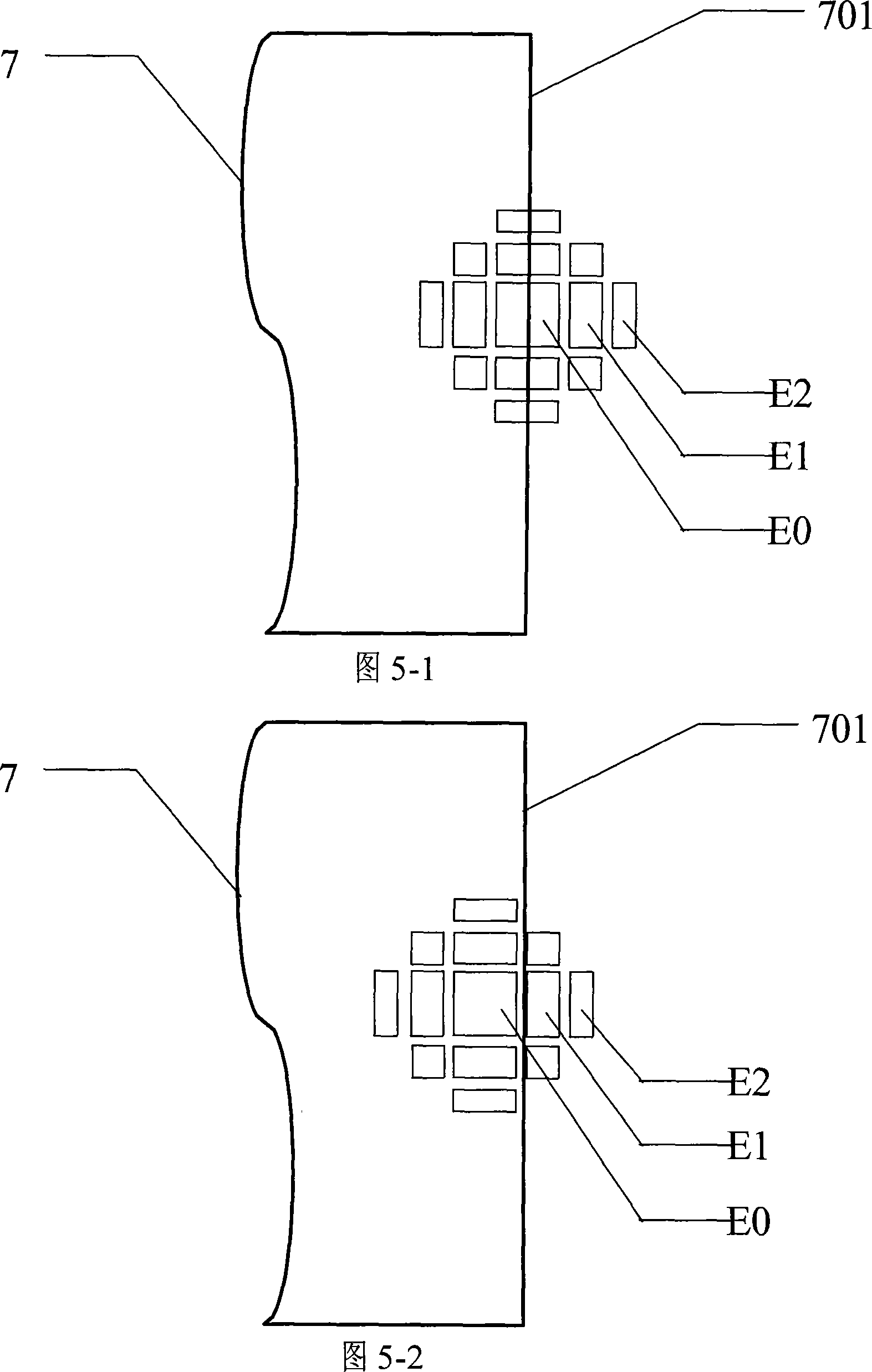

[0045] FIG. 5 shows the relative positional relationship between the diffraction spectrum formed by the light beam reflected by the microbeam on the rear focal plane of the converging lens 6 and the optical filter unit 7 when the structure shown in FIG. 1 is adopted.

[0046] Figure 5-1 shows the relative positional relationship between the optical filter unit 7 and the diffraction spectrum when the microbeam is not heated;

[0047] Figure 5-2 shows the relative positional relationship between the optical filter unit 7 and the diffraction spectrum after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com