Method for preparing molecular brand filling

A technology of molecular imprinting and polymerization, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, solid solvent extraction, etc. and other problems, to achieve the effect of small column pressure, reducing dosage and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

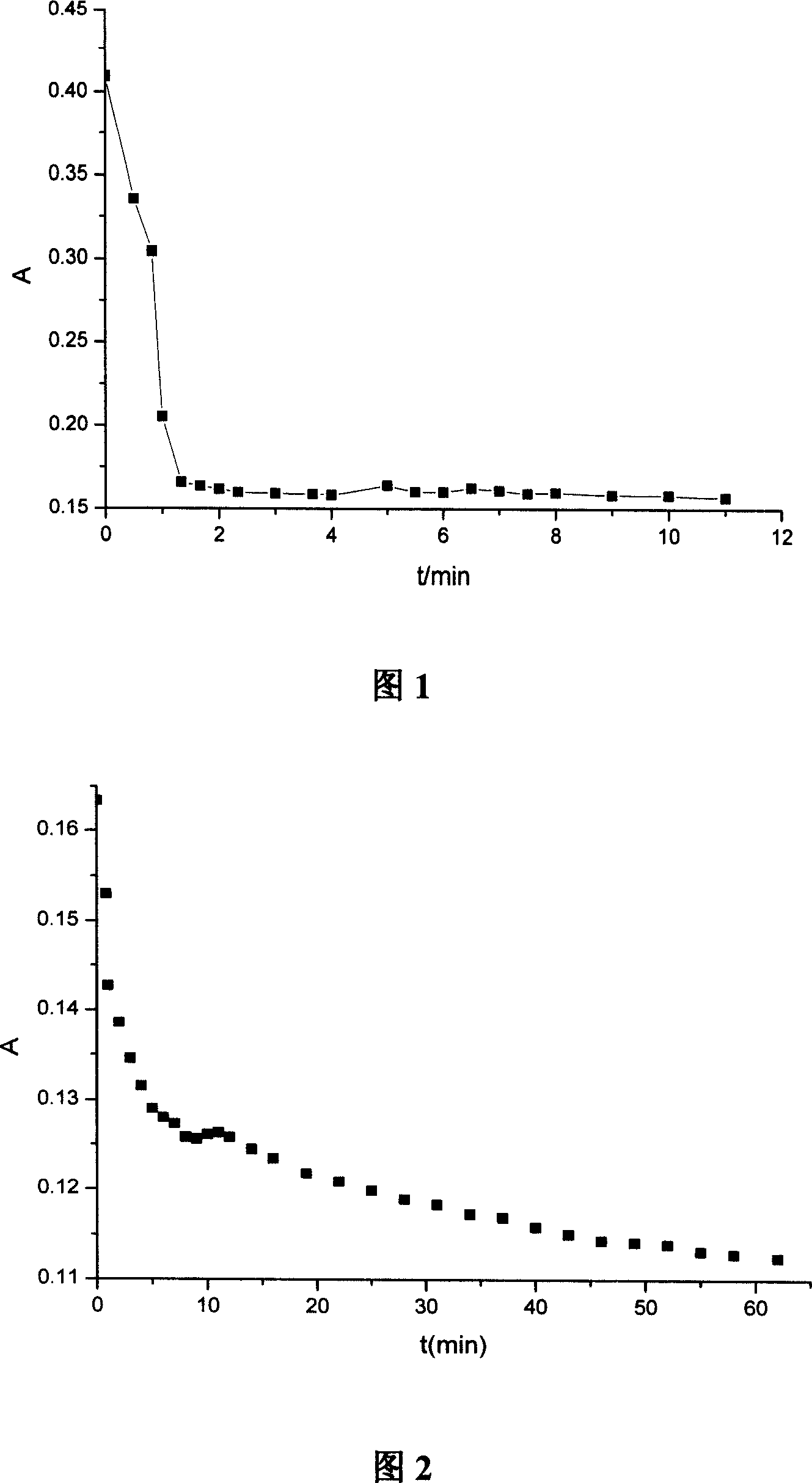

Image

Examples

Embodiment

[0042] 1. Experimental materials

[0043] 1.1 Source

[0044] Emodin was purchased from Huaian Jiutai Biochemical Co., Ltd., with a purity greater than 98%.

[0045]Acrylamide (AA), trimethylolpropane trimethacrylate (TRIM), and azobisisobutyronitrile (AIBN) were purchased from Bailingwei Chemical Reagent Company. TRIM was treated as follows before use: TRIM was washed with 10% aqueous sodium hydroxide solution, dried with anhydrous magnesium sulfate, and then redistilled under reduced pressure. AIBN was recrystallized from methanol before use.

[0046] Tetrahydrofuran (THF) is chromatographically pure, dried over sodium and redistilled before use. Methanol and acetonitrile are chromatographically pure, and acetic acid is analytically pure.

[0047] 500-mesh hollow glass microspheres, triethoxyvinylsilane and triethoxyaminoethylsilane were purchased from Qingdao Haid Chemical Reagent Company.

[0048] 0.75mm inner diameter PEEK tubes and various PEEK joints (concave and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com