Boiler type shaped coal and its production method

A boiler and pulverized coal technology, which is applied in the petroleum industry, solid fuel, fuel, etc., can solve problems such as the difficulty of burning briquette coal, and achieve the effects of good promotion and application prospects, simple and feasible production methods, and reasonable formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Boiler briquette formula: 160 kg of pulverized coal: 18 kg of MgO, 2 kg of combustion improver, 18 kg of magnesium chloride aqueous solution with a concentration of 9%, MnO 2 1 kg.

[0025] Production steps of briquette: add magnesium oxide into pulverized coal according to the above amount, stir and mix, then add magnesium chloride solution, stir and mix, soak for 10 minutes, stir and mix again; extrude the mixed material, and maintain it at room temperature Dry for 36 hours, then pile up and store in the natural environment for 2 days to get the boiler briquette product, the quality index of which is shown in Table 1.

[0026] The pulverized coal is the product of Wangjiazhuang Coal Mine in Taiyuan City, and its quality indicators are shown in Table 1.

[0027] Table 1 Test results of briquette products and pulverized coal

[0028] serial number

[0029] 2

Embodiment 2

[0031] Briquette production step is with embodiment 1.

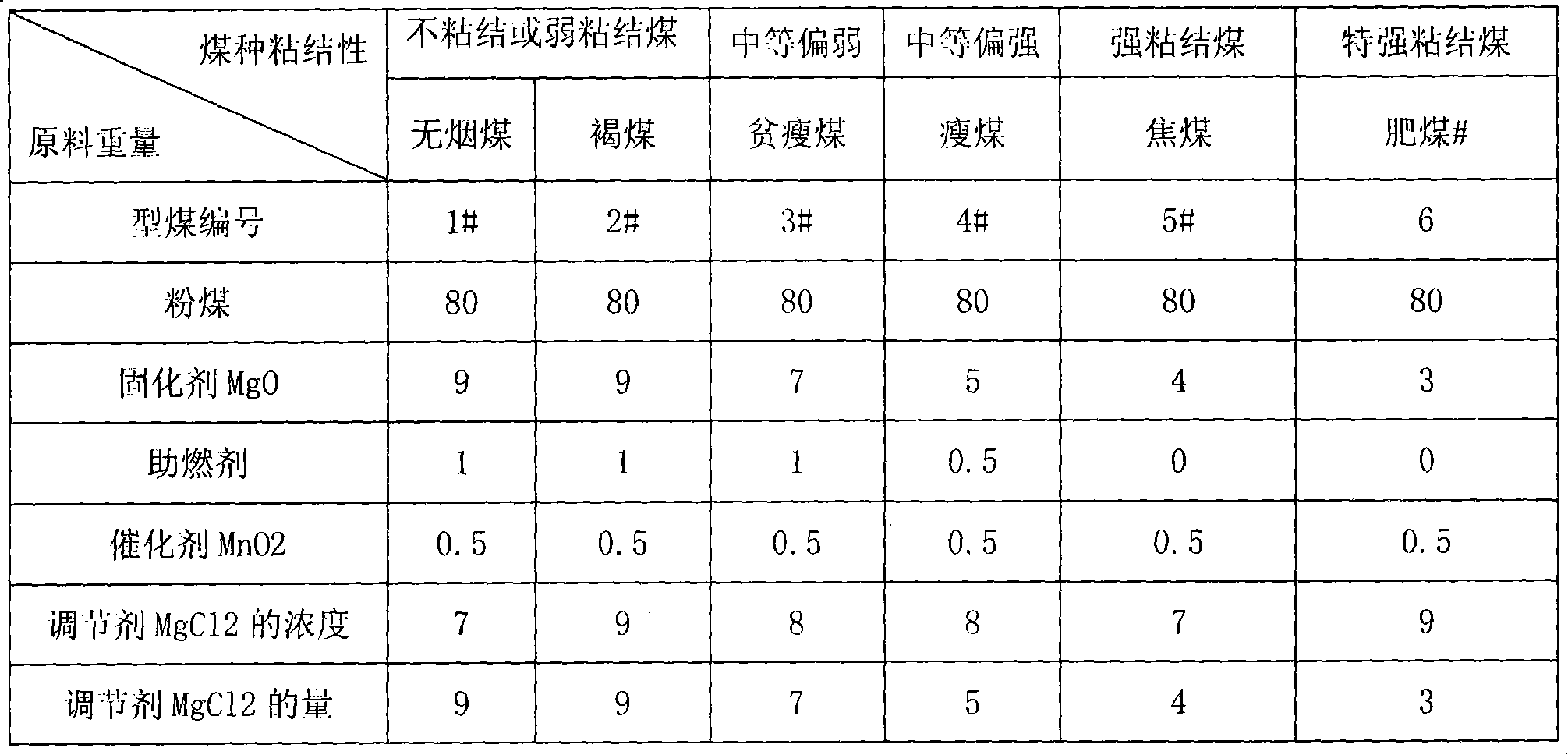

[0032] According to the difference of coal quality, adjust the formula as shown in Table 2,

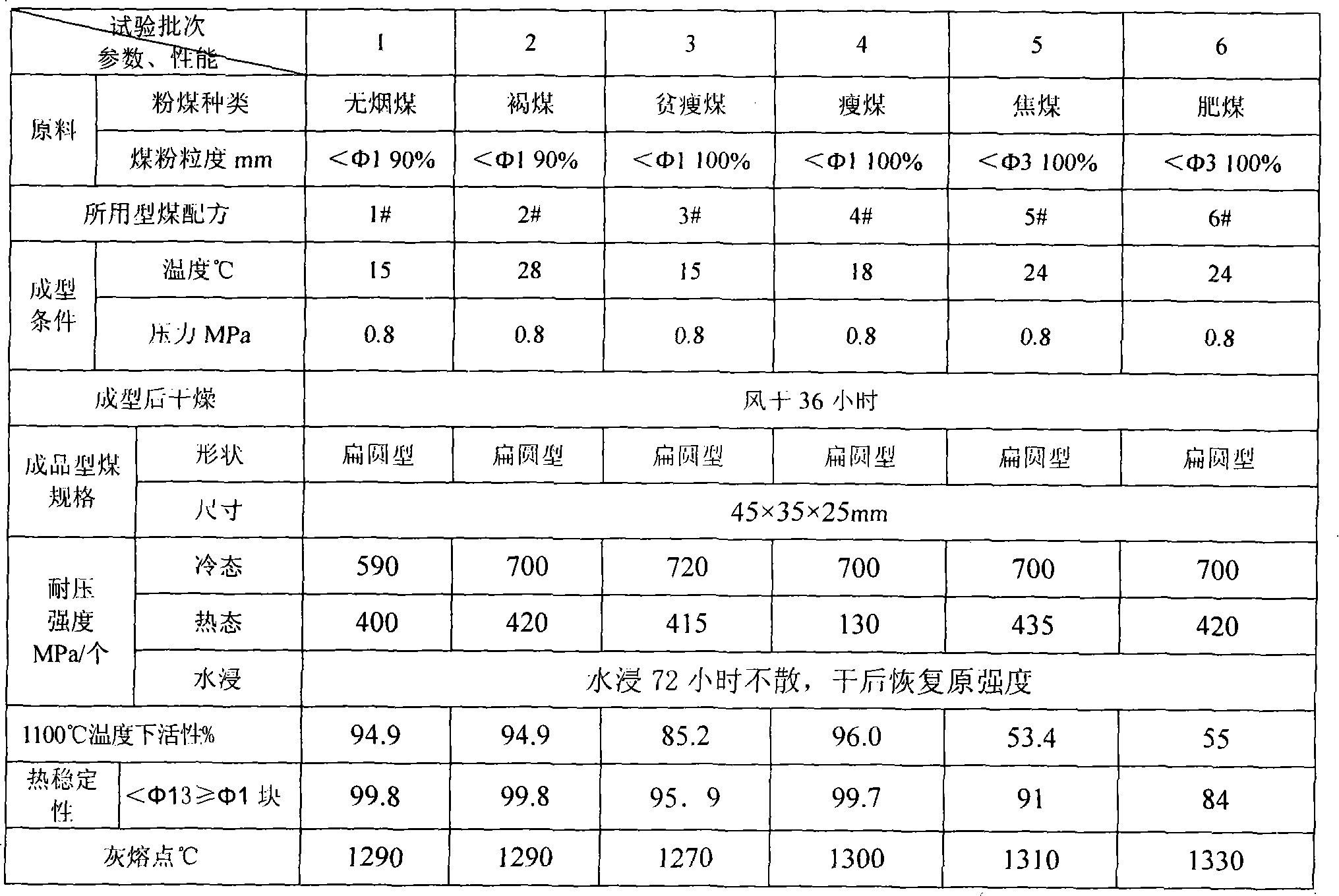

[0033] The test results of briquette products obtained from different formulations are shown in Table 3.

[0034] Formulations of briquettes with different coal qualities in Table 2. The unit is Kg

[0035]

[0036] Table 3 Test results of briquette products obtained by different formulations

[0037]

Embodiment 3

[0039] Briquette formula: only the amount of manganese dioxide in the formula is changed to zero, and other is the same as embodiment 1.

[0040] Briquette production step is with embodiment 1. The combustion performance of the briquette and its comparison with that of the briquette containing manganese dioxide are shown in Table 4.

[0041] Comparison of combustion performance of three embodiments of table 4 briquettes

[0042]

[0043] It can be seen from the examples that the formula of the boiler briquette of the present invention is reasonable, can be adjusted according to the coal quality and the performance of the combustion boiler, and the production method is feasible. Performance, especially the addition of manganese dioxide in the formula has a significant effect on the combustion performance and desulfurization effect of the briquette, and has a good prospect for popularization and application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com