Method of manufacturing charged particle, charged particle, electrophoretic dispersion liquid, electrophoretic sheet, electrophoretic device and electronic equipment

A technology of charged particles and a manufacturing method, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of large electric field, difficulty in obtaining charged amount of electrophoretic particles, and large power consumption of electrophoretic display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

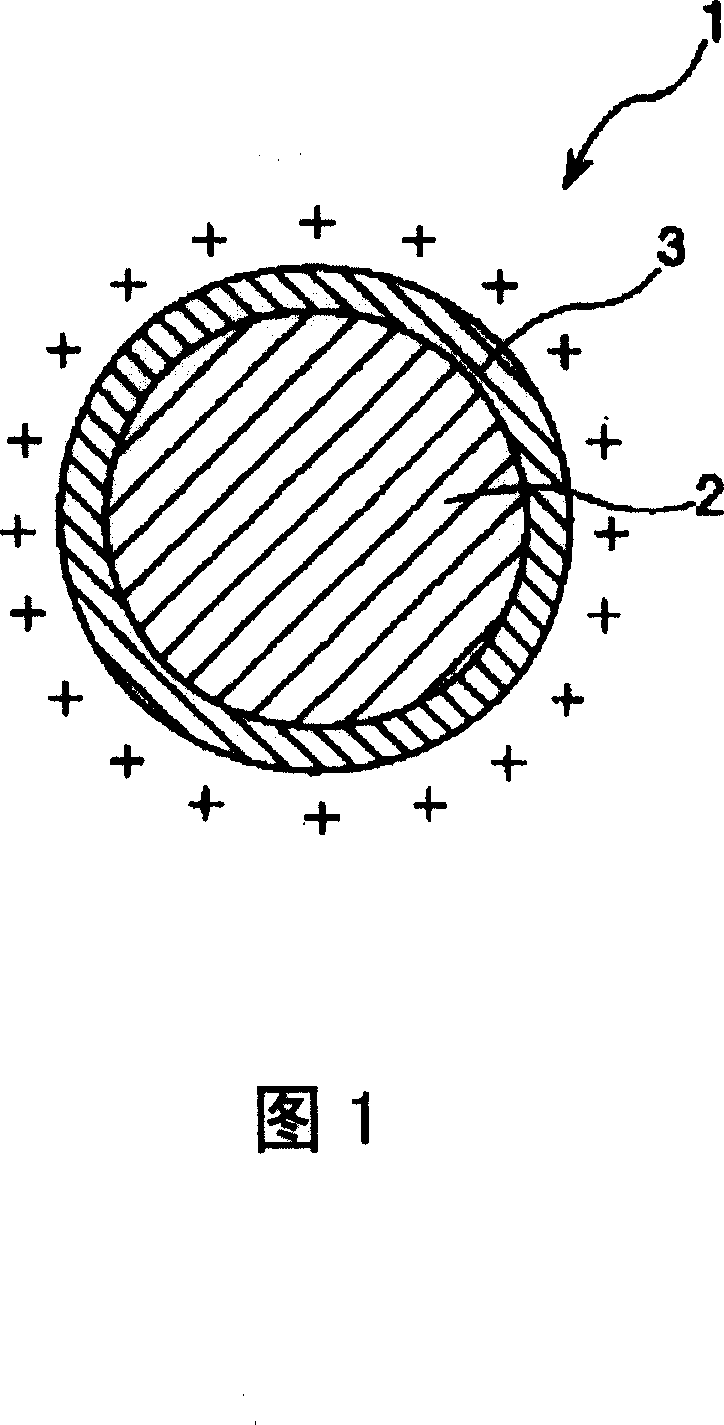

[0102] The charged particles of the first embodiment are positively charged charged particles (positively charged particles).

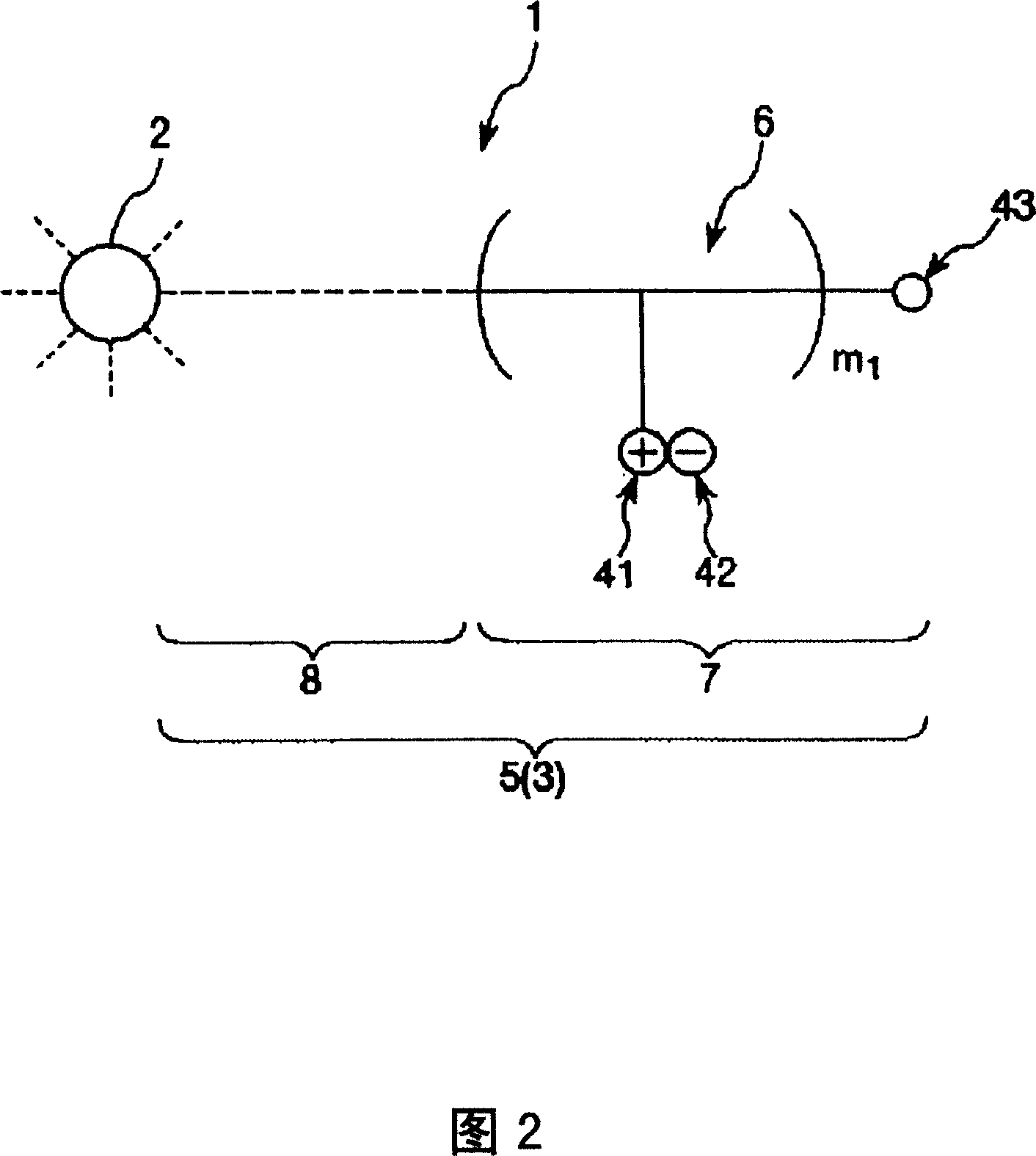

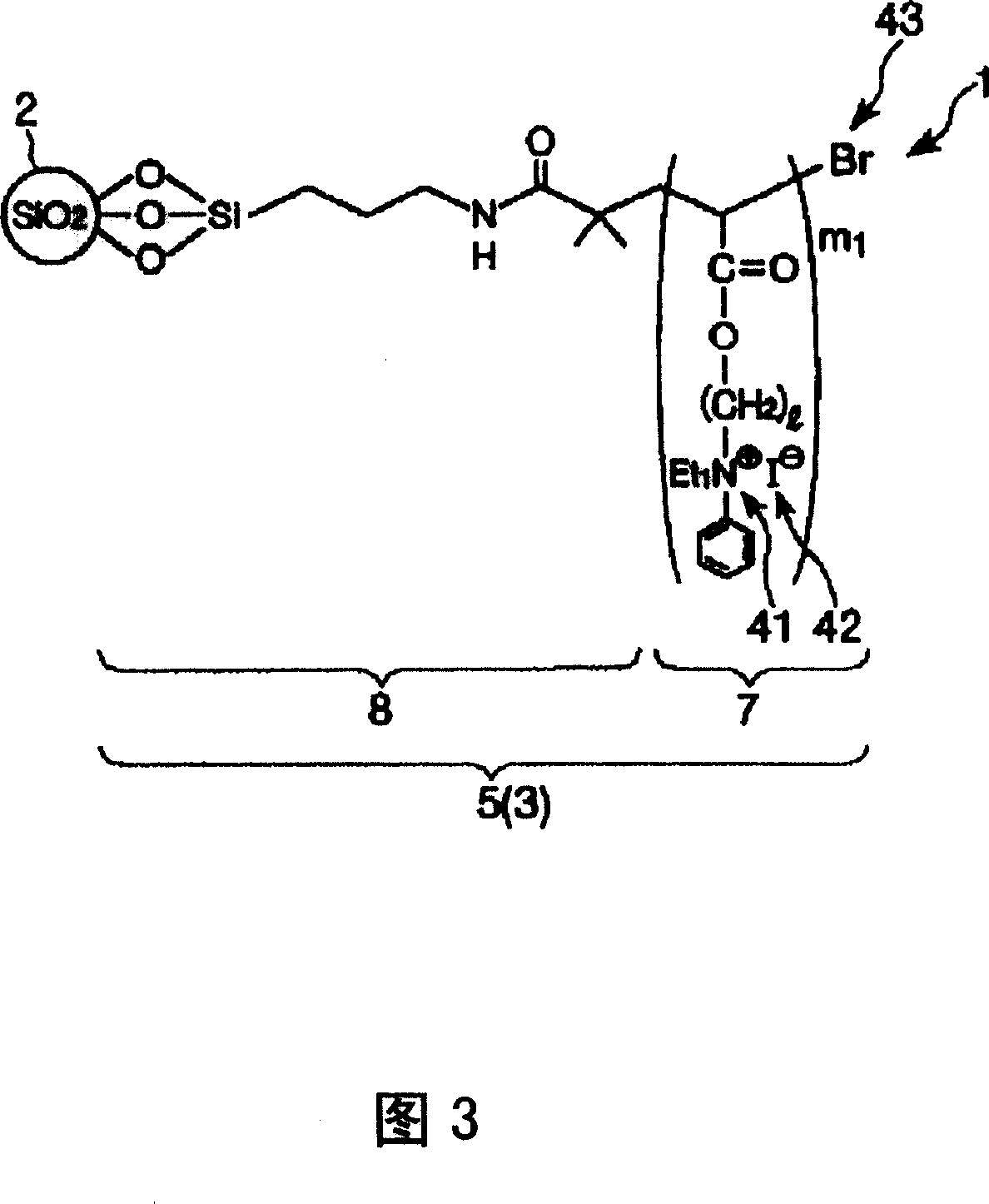

[0103] 1 is a longitudinal sectional view showing a first embodiment of the charged particle of the present invention, FIG. 2 is a schematic view showing the polymer structure of the charged particle shown in FIG. 1 , and FIG. 3 shows an example of the polymer shown in FIG. 2 schematic diagram.

[0104] A charged particle 1 shown in FIG. 1 has a mother particle 2 and a coating layer 3 provided on the surface of the mother particle 2 .

[0105] As the mother particle 2, for example, at least one of pigment particles, resin particles, or composite particles thereof is suitably used. These particles are easy to manufacture.

[0106] Examples of pigments constituting pigment particles include black pigments such as aniline black, carbon black, and titanium black, white pigments such as titanium dioxide, antimony trioxide, barium sulfate, zinc sulfide, z...

no. 2 approach

[0186] Next, a second embodiment of the charged particles of the present invention will be described.

[0187]Hereinafter, the charged particles 1 of the second embodiment will be mainly described in terms of differences from the charged particles 1 of the first embodiment described above, and descriptions of the same matters will be omitted.

[0188] FIG. 5 is a schematic view showing the constitution of a polymer included in the charged particle of the second embodiment, and FIG. 6 is a schematic view showing an example of the polymer shown in FIG. 5 .

[0189] The charged particles 1 of the second embodiment are positively charged particles (positively charged particles), but the structure of the polymer 5 constituting the coating layer 3 is different, and are basically the same as the charged particles 1 of the above-mentioned first embodiment.

[0190] That is, the polymer 5 of the second embodiment has a cationic group 41 at the terminal (the other end) of the main chain...

no. 3 approach

[0231] Next, a third embodiment of the charged particles of the present invention will be described.

[0232] Hereinafter, regarding the charged particle 1 of the third embodiment, differences from the charged particle 1 of the above-mentioned first embodiment will be mainly described, and descriptions of the same items will be omitted.

[0233] 8 is a longitudinal sectional view showing a third embodiment of the charged particle of the present invention, FIG. 9 is a schematic view showing the structure of a polymer having the charged particle shown in FIG. 8 , and FIG. 10 is a view showing one of the polymers shown in FIG. Schematic diagram of the example.

[0234] The charged particles 1 shown in FIG. 8 are negatively charged particles (negatively charged particles), and are basically the same as the charged particles of the above-mentioned first embodiment except that the composition of the covering layer 3 is different.

[0235] That is, the structure of the covering laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com