Hierarchical fuzzy control method for numerical control milling process

A machining process, CNC milling technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of low metal cutting rate, cutting chip thickness, tool wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

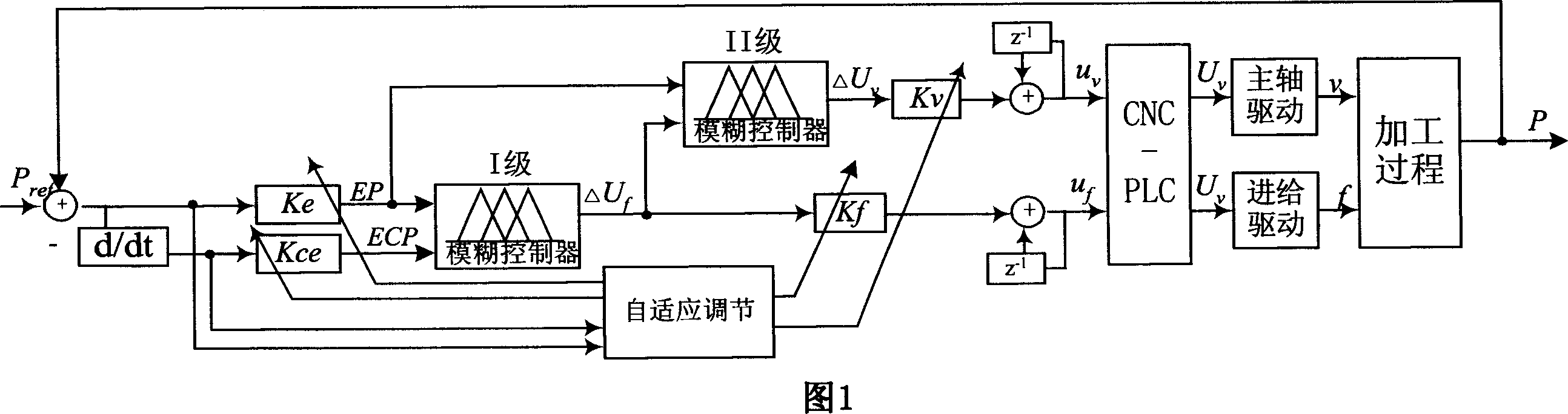

[0022] As shown in Fig. 1, it is the schematic diagram of hierarchical fuzzy hierarchical control of the present invention, P in the figure ref In order to set the reference spindle power value, the figure shows the relationship between the input and output of the I-level and II-level fuzzy controllers. The I-level fuzzy controller takes the power deviation value EP and the deviation change value ECP as input, and after quantization factor Ke , and Kce transformation after domain transformation and fuzzy processing, input the fuzzy reasoning machine, apply the Mamdani reasoning method to reason according to the given knowledge rules, the obtained fuzzy quantity is defuzzified by the center of gravity method, and the output of the I-level fuzzer is further Adjustment variation ΔU in the fuzzy domain of given multiplier f , the level II fuzzy controller uses the power deviation value EP and ΔU f As the input, enter the fuzzy reasoning machine, apply the Mamdani reasoning method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com