Cotton transfer printing paper and its machining method

A technology of transfer printing paper and printing, which is applied in the direction of transfer printing method, printing process, copying/marking method, etc., and can solve the problems of shortened transfer time and inability to realize transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

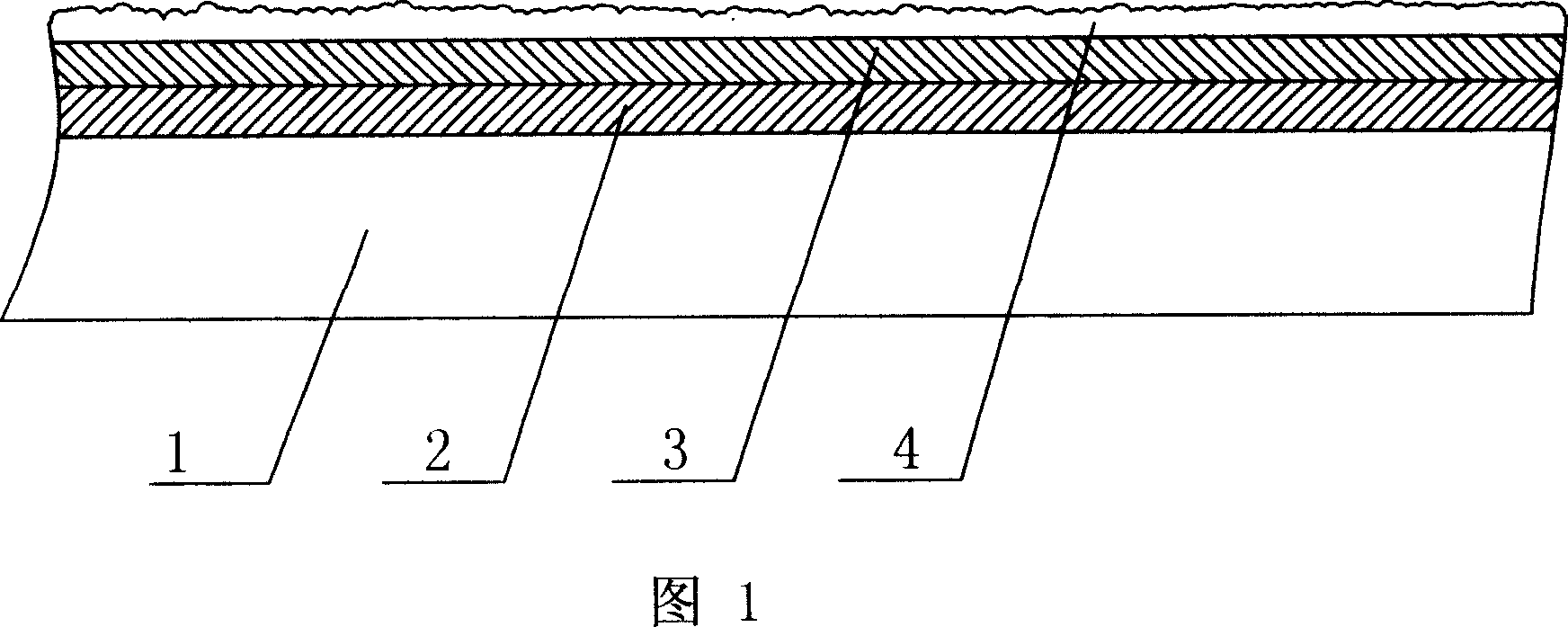

[0010] See Fig. 1, comprise paper 1, isolation layer and dyestuff layer among the present invention, be coated with sodium silicate glass fluid layer 2 on the surface of paper 1, then be coated with printing pattern on the surface of the sodium silicate glass fluid layer 2 after drying The dye layer 4, the dye layer 4 is a vinyl sulfone type reactive dye layer, because the vinyl sulfone type reactive dye has good stability when it is slightly acidic, that is, the acidic environment can stabilize or slow down the hydrolysis rate of the dye, which is beneficial to the printing of the color paste The same color in the process is also conducive to the preservation and reuse of excess slurry, which reduces waste and pollution, and acidic substances can react with alkaline substances in the sodium silicate glass liquid layer in a short time to form The gel 3, on the one hand, the gel 3 forms an isolation layer together with the rest of the sodium silicate glass liquid layer 2, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com