Preparation method of oligosiloxane composite proton exchange membrane containing azole ring

An oligosiloxane, proton exchange membrane technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve problems such as the decline of proton conductivity, achieve good compatibility, high proton conductivity, guarantee The effect of mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

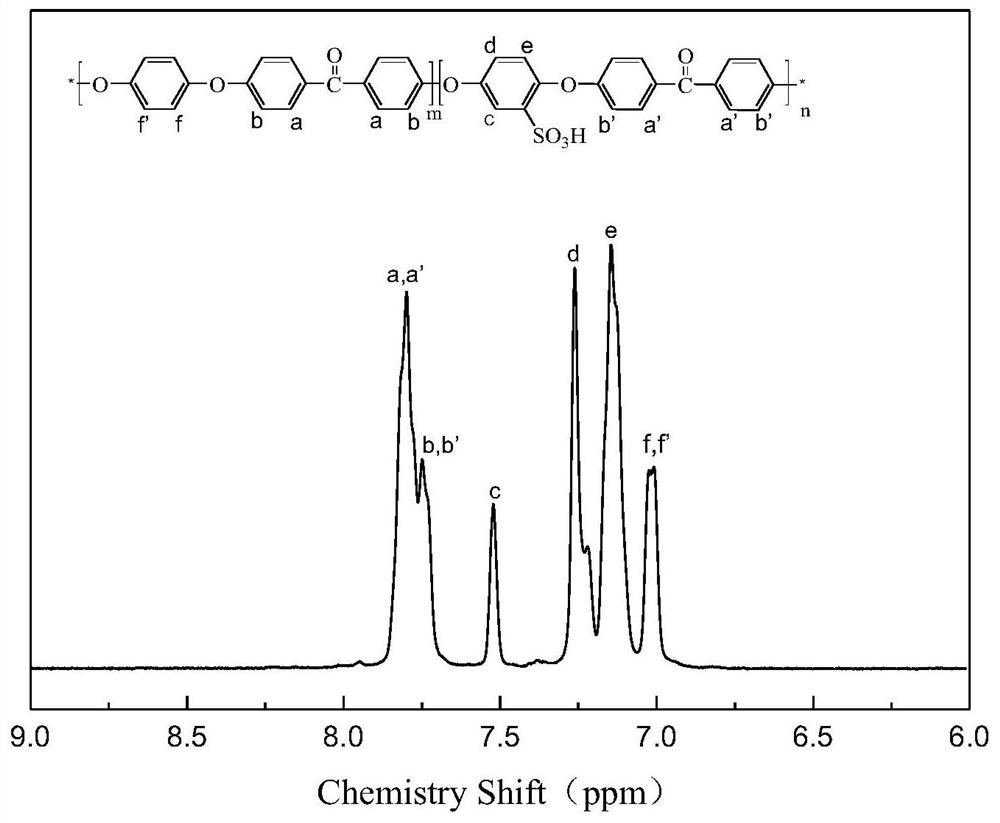

Embodiment 1

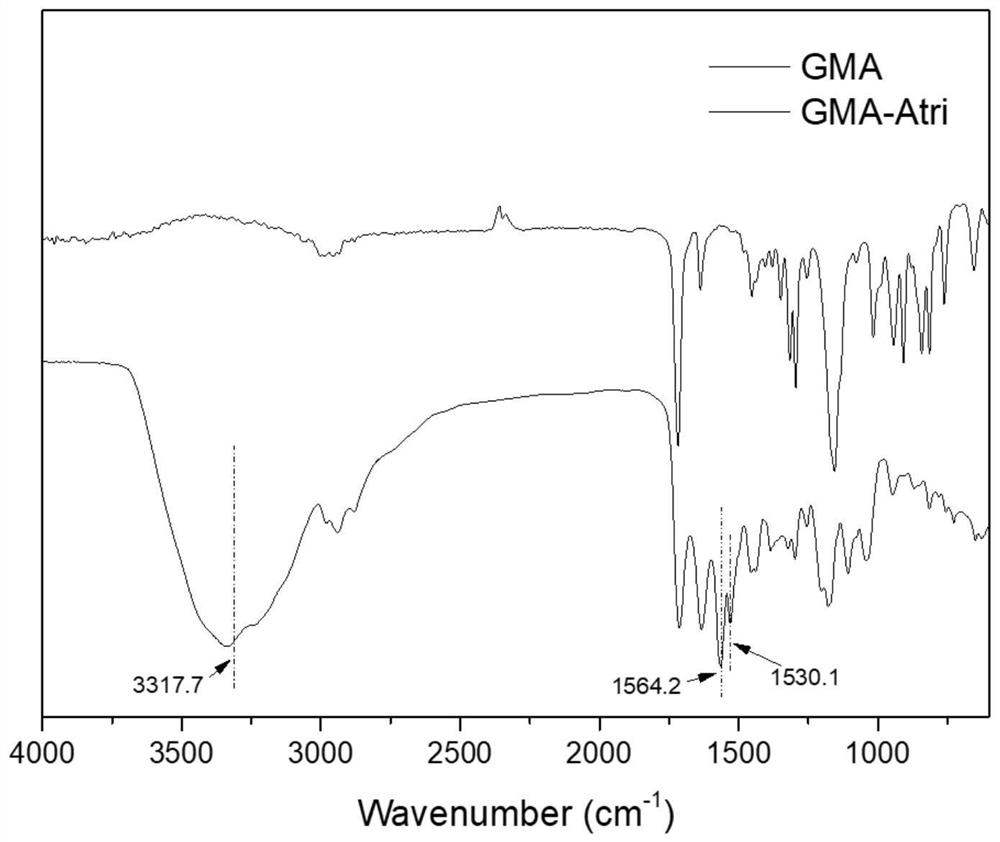

[0041] (1) Add 3-amino-1,2,4-triazole (Atri) to isopropanol to disperse evenly at 25°C, then add glycidyl methacrylate (GMA), react for 24 hours, and pass The solvent was removed by evaporation to give glycidyl methacrylate-3-amino-1,2,4-triazole (GMA-Atri);

[0042] Wherein, the mass ratio of 3-amino-1,2,4-triazole (Atri) to glycidyl methacrylate (GMA) is 8:11; 34 grams of Atri are added per liter of isopropanol;

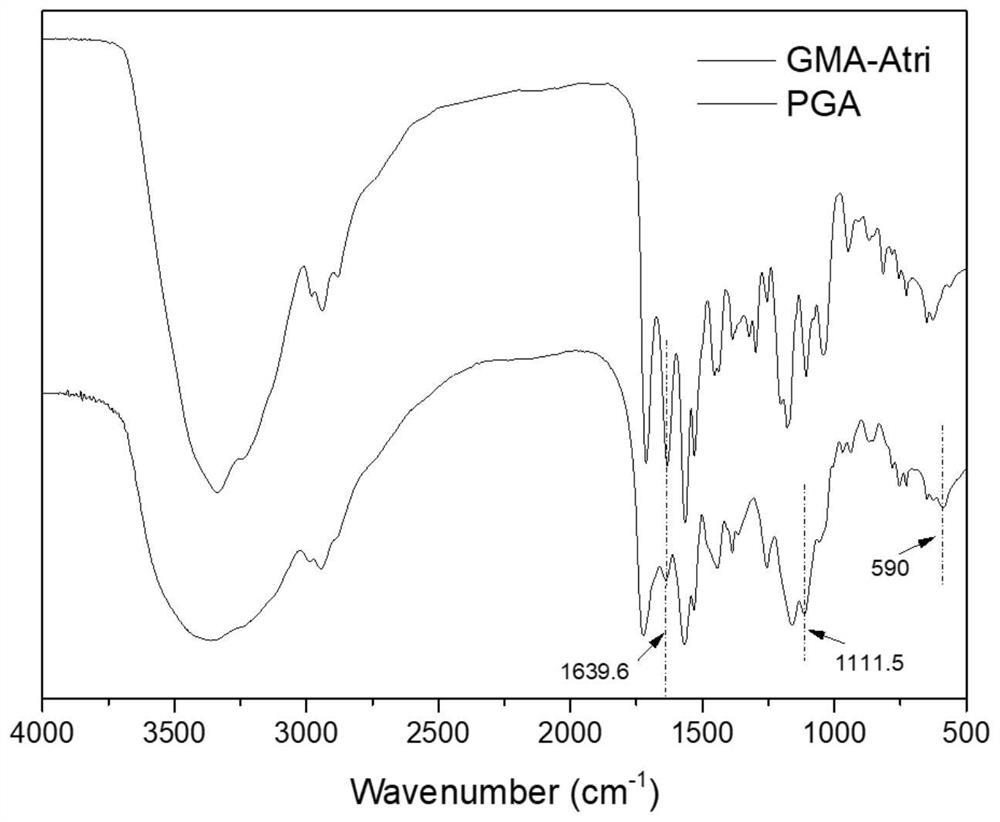

[0043] (2) Disperse GMA-Atri in deionized water at 70°C, add the initiator AIBN to start the reaction, add octavinyl octasilsesquioxane (OVPOSS) after 1 hour of reaction, and react for another 6 hours, and the obtained The product is precipitated in methanol, and then dried in a vacuum oven to obtain the desired oligosiloxane nanofiller PGA containing an azole ring;

[0044] Wherein, the mass ratio of GMA-Atri and OVPOSS is 90:1; The quality of adding initiator is 1% of the sum of monomer 3 and monomer 4 quality; Add 75 grams of GMA-Atri per liter of deionized wat...

Embodiment 2

[0067] Other steps are the same as in Example 1, except that Atri is replaced by Tri(1H-1,2,4-triazole). The obtained monomer 3 is GMA-Tri (glycidyl methacrylate-1H-1,2,4-triazole), and finally PGT (oligosiloxane organic-inorganic composite filler containing azole ring) is obtained. The performance of the obtained composite membrane is close to that of Example 1.

Embodiment 3

[0069] Other steps are the same as in Example 1, except that SPEEK is replaced by SPES (sulfonated polyarylethersulfone), and finally the composite membrane obtained is SPES / PGA-X. The performance of the obtained composite membrane is close to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com