Composite electrolytic bath and method for electrolyzing and decoloring pulp-making effluent

A technology for pulping waste liquid and electrolyzer, applied in the field of composite electrolyzer, can solve the problems of coagulant deactivation, high price and high processing cost, and achieve the effects of improving efficiency, convenient operation and maintenance, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The method of the present invention is used to treat the blue eucalyptus mechanical pulp wastewater, and the wastewater quality is: chromaticity: 6490C.U. COD: 11600mg / L, BOD: 2920mg / L, SS: 1390mg / L.

[0032] (1) The waste liquid is first filtered with a slanting screen, the screen is 80 mesh; after the fiber is recovered, it enters the sump.

[0033] (2) Add hydrochloric acid to reduce the acidity of the waste liquid to a pH value of 3; precipitate for 2 hours, acid analysis of lignin occurs, and precipitate part of the chromatic pollutants and most of the suspended matter.

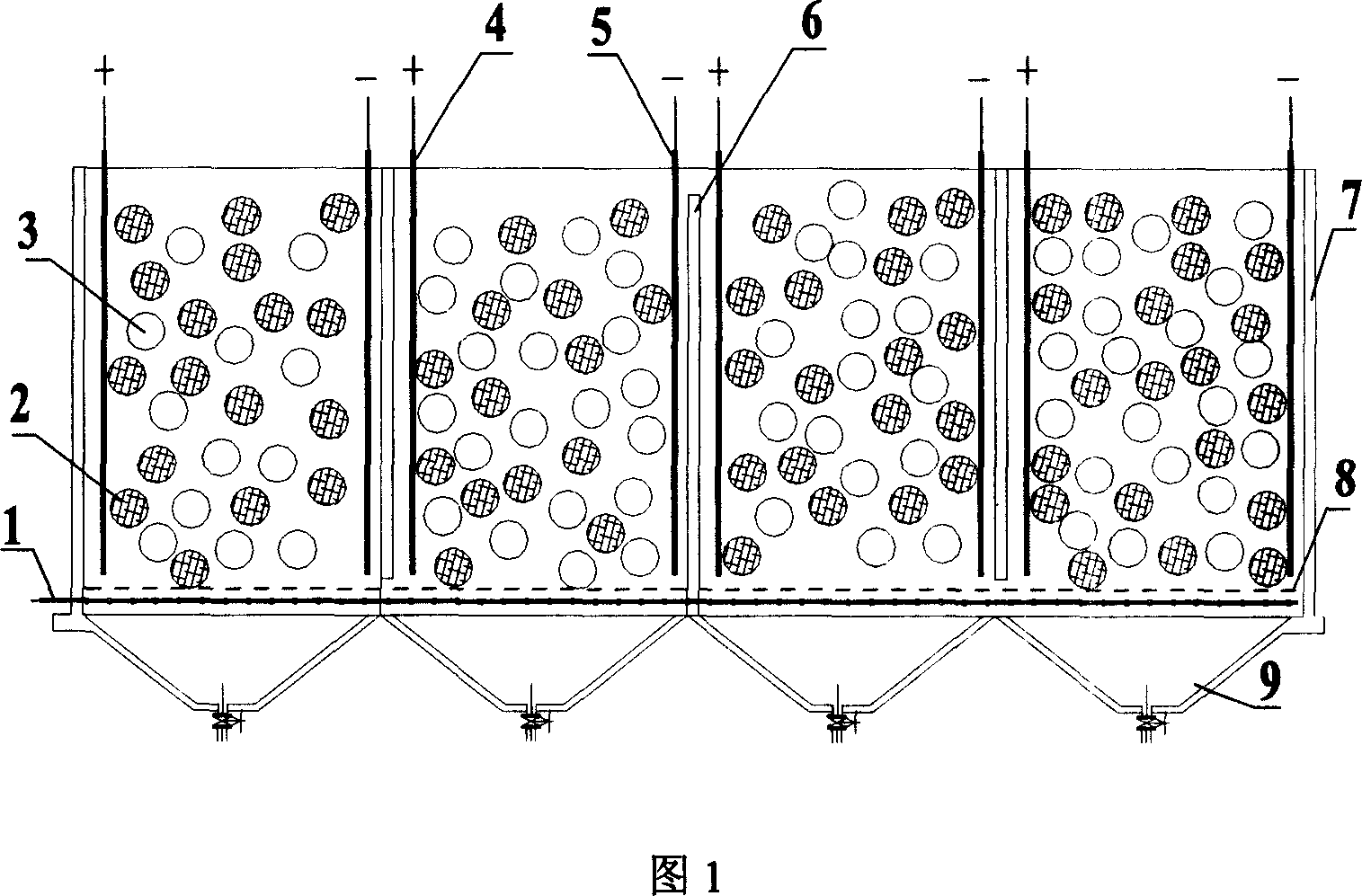

[0034] (3) The precipitated water body obtained in step (2) enters the composite electrolysis wastewater treatment device, and the composite micro-electrolysis wastewater treatment device effectively combines three-dimensional electrodes, electrocatalytic oxidation and micro-electrolysis technologies.

[0035] Among them, the interior of the composite electrolytic cell (7) divides the reactor into ...

Embodiment 2

[0046] Using the method of the present invention to treat poplar chemical-mechanical pulp wastewater, the wastewater quality is: chroma: 5890C.U., COD: 8600mg / L, BOD: 2120mg / L, SS: 560mg / L.

[0047] (1) The waste liquid is first filtered with a slanted screen with a screen size of 50 mesh; after fiber recovery, it enters the sump.

[0048] (2) Add hydrochloric acid to reduce the acidity of the waste liquid to a pH value of 3.5; precipitate for 1.5 hours, acid analysis of lignin occurs, and precipitate part of the chromatic pollutants and most of the suspended solids.

[0049] (3) The precipitated water body obtained in step (2) enters the composite electrolysis wastewater treatment device, and the composite micro-electrolysis wastewater treatment device effectively combines three-dimensional electrodes, electrocatalytic oxidation and micro-electrolysis technologies.

[0050] Among them, the interior of the composite electrolytic cell (7) divides the reactor into four chambers ...

Embodiment 3

[0061] Using the method of the present invention to treat poplar chemical-mechanical pulp wastewater, the wastewater quality is: chroma: 3890C.U., COD: 4600mg / L, BOD: 920mg / L, SS: 370mg / L.

[0062] (1) The waste liquid is first filtered with a slanted screen with a screen size of 50 mesh; after fiber recovery, it enters the sump.

[0063] (2) Add hydrochloric acid to reduce the acidity of the waste liquid to a pH value of 4; after 1.5 hours of precipitation, acid analysis of lignin occurs, and some chromatic pollutants and most of the suspended matter are precipitated.

[0064] (3) The precipitated water body obtained in step (2) enters the composite electrolysis wastewater treatment device, and the composite micro-electrolysis wastewater treatment device effectively combines three-dimensional electrodes, electrocatalytic oxidation and micro-electrolysis technologies. Among them, the interior of the composite electrolytic cell (7) divides the reactor into four chambers through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com