Process for producing isovitamine C by membrane-resin method

A technology of isovitamins and resins, which is applied in the field of chemical technology, can solve problems such as interference with crystal formation, interference with esterification, transformation, and heavy environmental protection burdens for manufacturers, so as to reduce the production of melanin-like melanin, reduce Maillard reactions, and reduce The effect of depigmentation burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

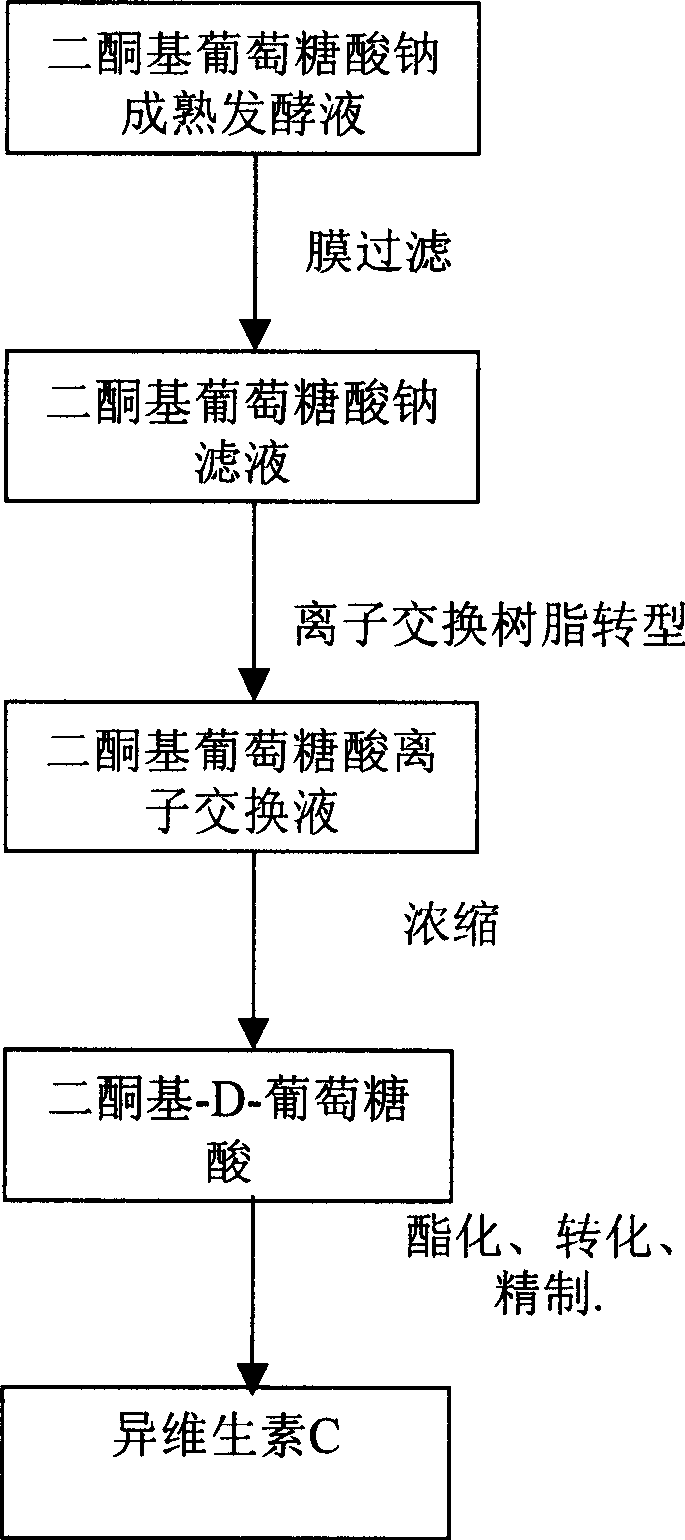

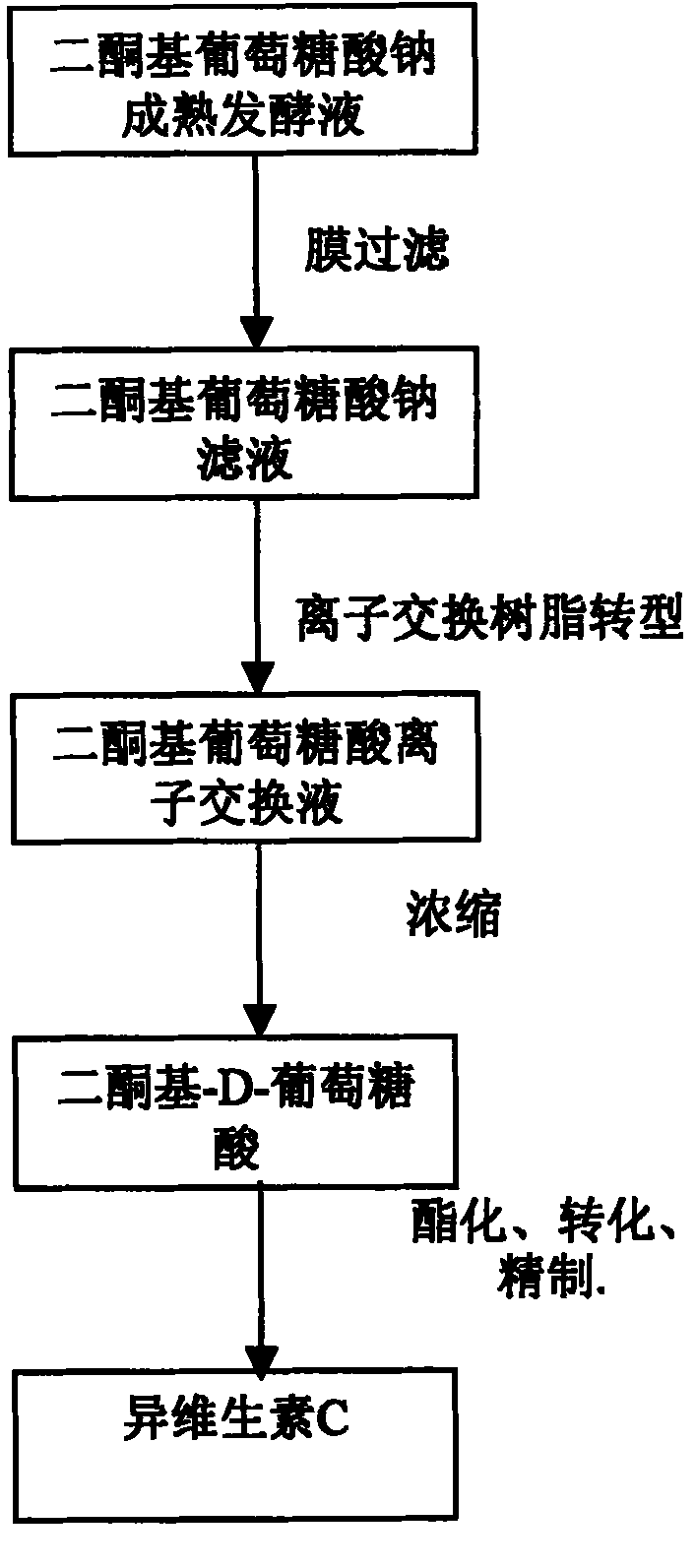

Embodiment 1

[0038] Diketogluconate sodium mature fermentation liquid is used as raw material, stainless steel membrane is used as the sterilization filter membrane, and the operating pressure is controlled at 4-5kg / cm 2 , control the operating temperature at 35-40° C., filter the diketogluconate sodium mature fermentation broth, and obtain a clear and transparent diketogluconate sodium filtrate. Then the filtrate is treated with a hydrogen-type cation exchange resin, the operating temperature is controlled to be 5-50°C, and the liquid flow rate is controlled to be 2-4 times the volume of the resin per hour, so that the diketogluconate sodium in the filtrate is transformed into diketogluconate , to obtain an ion-exchange solution containing diketogluconic acid. Then, the ion-exchange solution is concentrated until there is no water and steamed out to obtain the diketo-D-gluconic acid of the present invention, and then esterified, transformed and refined to obtain the isovitamin C product. ...

Embodiment 2

[0040] Diketogluconate sodium mature fermentation liquid is used as raw material, ceramic membrane is used as filter membrane, and the operating pressure is controlled at 6-8kg / cm 2 , control the operating temperature at 60-80° C., filter the diketogluconate sodium mature fermentation broth, and obtain a clear and transparent diketogluconate sodium filtrate. Then the filtrate is treated with a hydrogen-type cation exchange resin, the operating temperature is controlled to be 5-50°C, and the liquid flow rate is controlled to be 4-7 times the volume of the resin per hour, so that the sodium diketogluconate in the filtrate is transformed into diketogluconate , to obtain an ion-exchange solution containing diketogluconic acid. Then, the ion-exchange solution is concentrated until there is no water and steamed out to obtain the diketo-D-gluconic acid of the present invention, and then esterified, transformed and refined to obtain the isovitamin C product.

Embodiment 3

[0042] Diketogluconate sodium mature fermentation broth is used as raw material, polyethersulfone membrane is used as filter membrane, and the operating pressure is controlled at 4-10kg / cm 2 , controlling the operating temperature to 10-50° C., filtering the diketogluconate sodium mature fermentation broth to obtain a clear and transparent diketogluconate sodium filtrate. Then the filtrate is treated with a hydrogen-type cation exchange resin, the operating temperature is controlled to be 5-50°C, and the liquid flow rate is controlled to be 6-9 times the volume of the resin per hour, so that the diketogluconate sodium in the filtrate is transformed into diketogluconate , to obtain an ion-exchange solution containing diketogluconic acid. Then, the ion-exchange solution is concentrated until there is no water and steamed out to obtain the diketo-D-gluconic acid of the present invention, and then esterified, transformed and refined to obtain the isovitamin C product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com