Preparation method of lycium barbarum polysaccharide-lycium barbarum seed oil soft capsule

A technology of Lycium barbarum polysaccharides and Lycium barbarum seed oil, which is applied in capsule delivery, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve problems such as inability to combine Lycium barbarum seed oil, polysaccharide flocculation and precipitation, and general product quality, and achieve significant in vitro Antioxidant activity, high biological activity, easy cleaning and recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

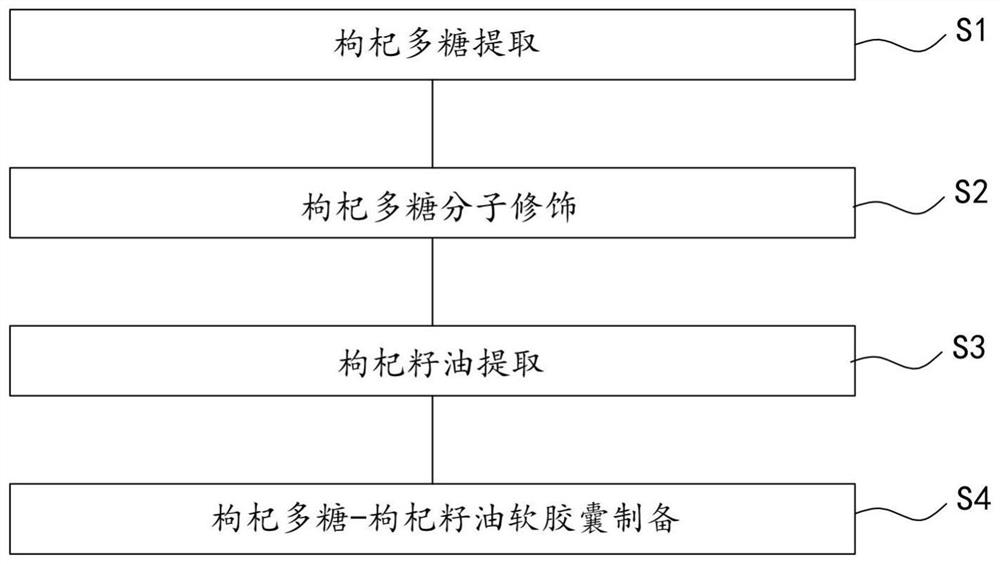

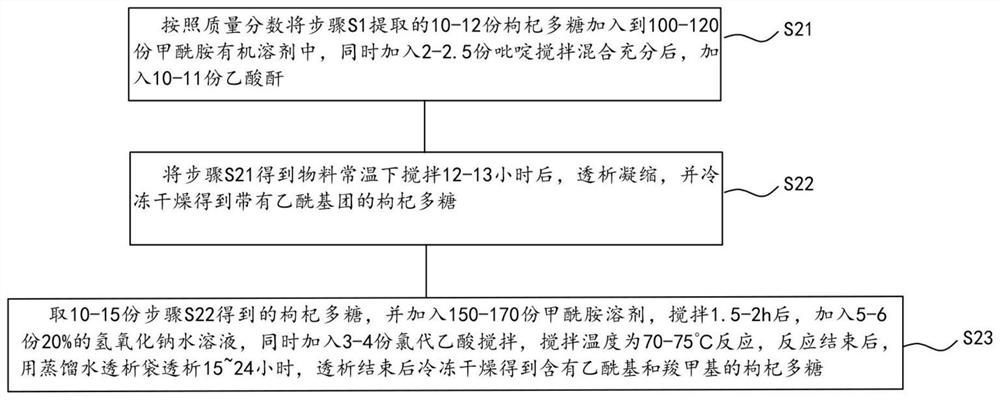

[0063] The preparation method of the wolfberry polysaccharide-lycium barbarum seed oil soft capsule comprises the following steps: S1 extraction of the wolfberry polysaccharide; S2 molecular modification of the wolfberry polysaccharide; S3 extraction of the wolfberry seed oil; S4 preparation of the wolfberry polysaccharide-lycium seed oil soft capsule.

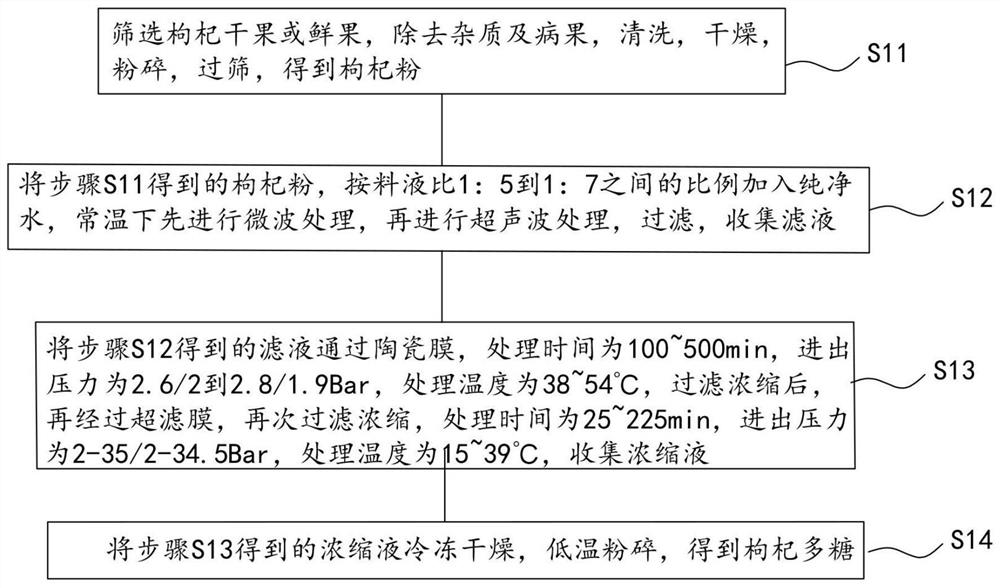

[0064] S1 Lycium barbarum polysaccharide extraction, including:

[0065] S11. Screen dried or fresh wolfberry fruit, remove impurities and diseased fruits, wash, dry, pulverize, sieve, and pass through a 40-mesh sieve to obtain wolfberry powder;

[0066] S12, take 10000g of wolfberry powder obtained in step S11, add pure water according to the ratio of material to liquid 1:6, carry out microwave treatment at room temperature first, microwave power 250w, processing time 10min; then carry out ultrasonic treatment, ultrasonic power 150w, ultrasonic frequency 25Hz , processing time 11min, filter, and collect the filtrate;

[0067...

Embodiment 2

[0085] The preparation method of wolfberry polysaccharide-lycium seed oil soft capsule comprises the following steps: S1 extraction of wolfberry polysaccharide; S2 molecular modification of wolfberry polysaccharide; S3 extraction of wolfberry seed oil; S4 preparation of wolfberry polysaccharide-lycium seed oil soft capsule

[0086] S1 Lycium barbarum polysaccharide extraction, including:

[0087] S11. Screen dried or fresh wolfberry fruit, remove impurities and diseased fruits, wash, dry, pulverize, sieve, and pass through a 40-mesh sieve to obtain wolfberry powder;

[0088] S12, take 10000g of wolfberry powder obtained in step S11, add pure water according to the ratio of material to liquid 1:5, carry out microwave treatment at room temperature first, microwave power 400w, processing time 14min; then carry out ultrasonic treatment, ultrasonic power 250w, ultrasonic frequency 25Hz , processing time 15min, filter, and collect the filtrate;

[0089] S13. Pass the filtrate obtai...

Embodiment 3

[0107] The preparation method of wolfberry polysaccharide-lycium seed oil soft capsule comprises the following steps: S1 extraction of wolfberry polysaccharide; S2 molecular modification of wolfberry polysaccharide; S3 extraction of wolfberry seed oil; S4 preparation of wolfberry polysaccharide-lycium seed oil soft capsule

[0108] S1 Lycium barbarum polysaccharide extraction, including:

[0109] S11. Screen dried or fresh wolfberry fruit, remove impurities and diseased fruits, wash, dry, pulverize, sieve, and pass through a 40-mesh sieve to obtain wolfberry powder;

[0110] S12, get 10000g of wolfberry powder obtained in step S11, add pure water according to the ratio of material to liquid ratio of 1:7, carry out microwave treatment at room temperature first, microwave treatment is microwave power 300w, treatment time 12min; then carry out ultrasonic treatment, ultrasonic power 200w, Ultrasonic frequency 25Hz, treatment time 14min, filter, collect filtrate;

[0111] S13. Pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com