Vinyon fiber of battery and its production and use

A production method, acrylic fiber technology, applied in fiber processing, lead-acid battery electrodes, textiles and papermaking, etc., can solve the problems of battery plate adding materials, acrylic fiber softness, etc., to achieve excellent acid and alkali resistance, The effect of extending the service life and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

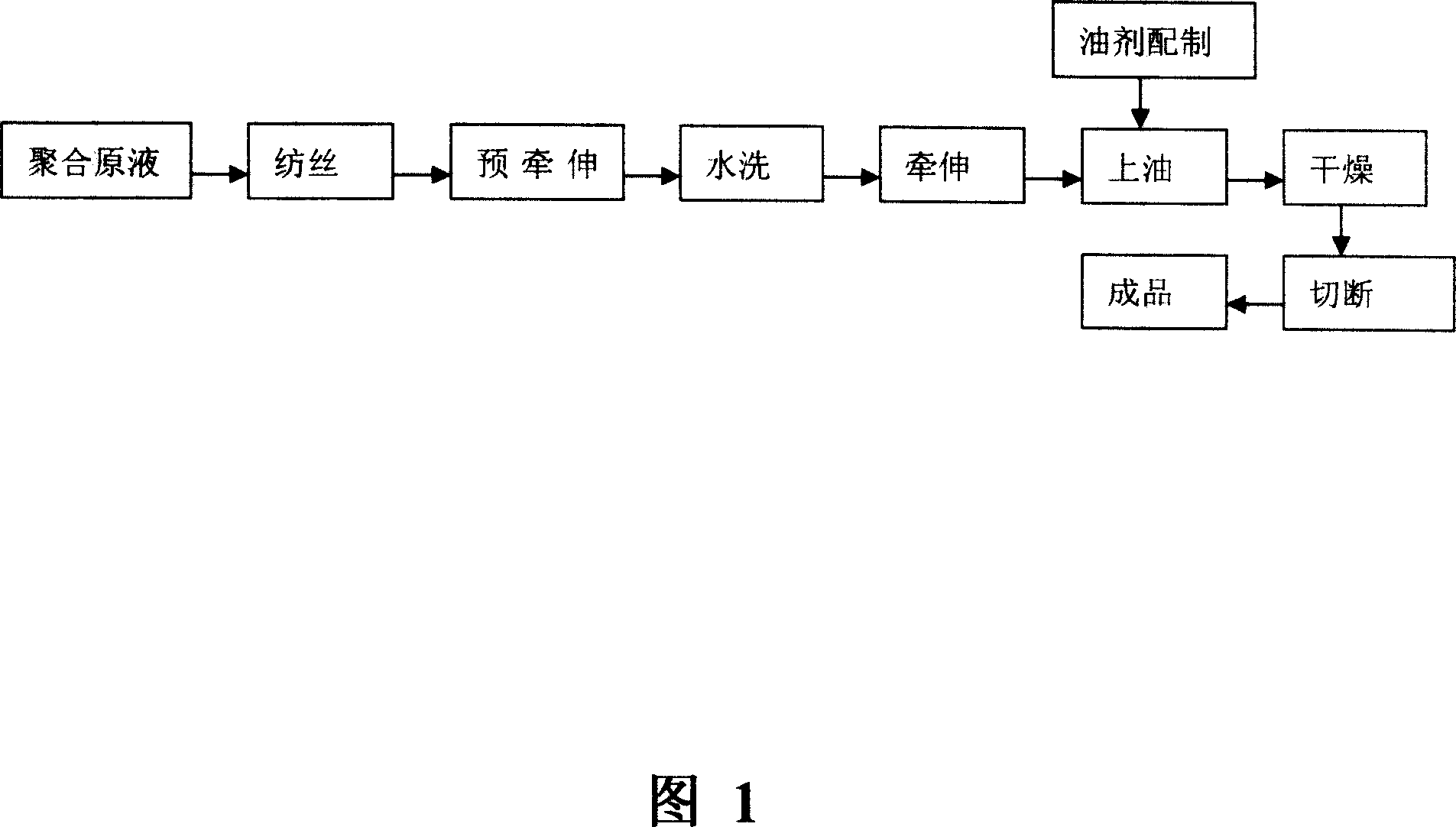

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1-in the same above-mentioned process operation process,

[0029] Oiling process: adjust the pH value of the solution to 4 during oil preparation;

[0030] Drying process: The temperature of each area of the dryer is set as follows: Zone 1 135°C, Zone 2 148°C, Zone 3 170°C, Zone 4 170°C, Zone 5 152°C, Zone 6 130°C.

Embodiment 2

[0031] Embodiment 2-in the same above-mentioned technological operation process,

[0032] Oiling process: adjust the pH value of the solution to 5 during oil preparation;

[0033] Drying process: The temperature setting of each area of the dryer is: 138°C in zone 1, 150°C in zone 2, 160°C in zone 3, 160°C in zone 4, 155°C in zone 5, and 135°C in zone 6.

Embodiment 3

[0034] Embodiment 3-in the same above-mentioned process operation process,

[0035] Oiling process: adjust the pH value of the solution to 6 during oil preparation;

[0036]Drying process: The temperature of each area of the dryer is set as follows: 1 zone 140°C, zone 2 145°C, zone 3 165°C, zone 4 165°C, zone 5 150°C, zone 6 140°C.

[0037] In each embodiment of described production method, the process parameter of other production processes is still identical with conventional acrylic fiber production, and its process index is as follows:

[0038] Spinning metering pump speed (rpm): 45

[0039] Spinning bath temperature (°C): 10~15

[0040] Spinning bath concentration (%): 50~55

[0041] Spinning bath flow (l / h): 4500

[0042] Collecting roller speed (m / min): 7.9

[0043] Pre-drawing speed (m / min): 37.5

[0044] Pre-drawing temperature (°C): 90~97

[0045] Pre-drawing flow (l / h): 1500

[0046] Washing speed (m / min): 37.5

[0047] Washing flow (l / h): 2000

[0048] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com