Crystal-coated light-emitting diodes packing structure and method

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of LED deterioration, small contact area, and reduced luminous efficiency, and achieve the best heat conduction and heat dissipation efficiency, and the best luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

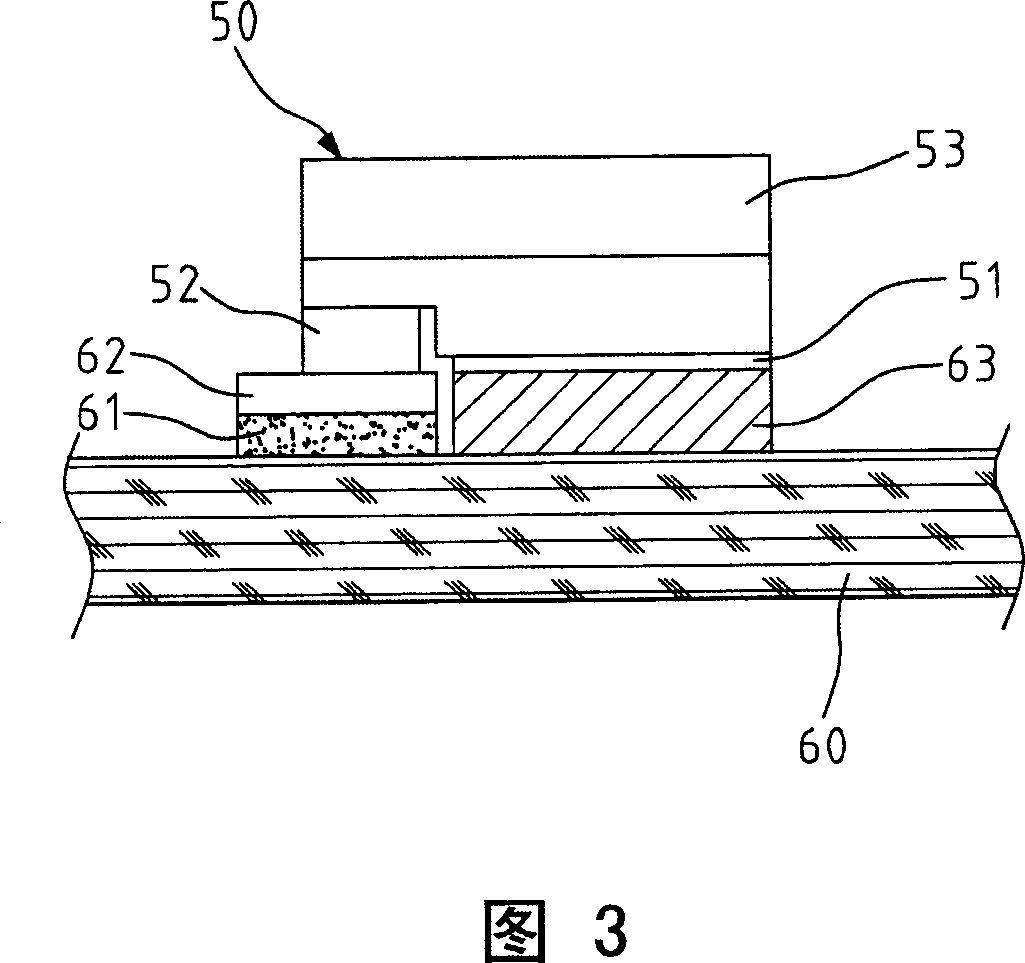

[0014] Referring to Fig. 3, this figure is a schematic diagram of an embodiment of the present invention. The package structure of the flip-chip light emitting diode of the present invention includes an LED 50 and a heat-conducting substrate 60 , and the LED 50 is packaged on the heat-conducting substrate 60 in a flip-chip manner.

[0015] The LED 50 includes a first electrode 51 and a second electrode 52 , the first electrode 51 and the second electrode 52 are located on the same side of the surface of the LED 50 . The electrodes can be made by plating titanium (Ti), aluminum or gold (Au) and other metal layers by physical vapor deposition (Physical Vapor Deposition, PVD), and then through metal fusion. On a general gallium nitride (GaN) LED chip, the first electrode 51 can be electrically connected to the P-type gallium nitride (P-GaN) layer to become a P-type electrode, while the second electrode 52 can be connected to the N-type nitrogen The gallium nitride (n+GaN) layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com