Clearance blast aeration oxidation ditch sewage treatment technology

A blowing aeration and sewage treatment technology, which is applied in the field of sewage treatment using gap aeration and oxidation structure technology, can solve the problems of high power consumption, difficult maintenance of aeration head, etc., and achieves good effect, small floor space and simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

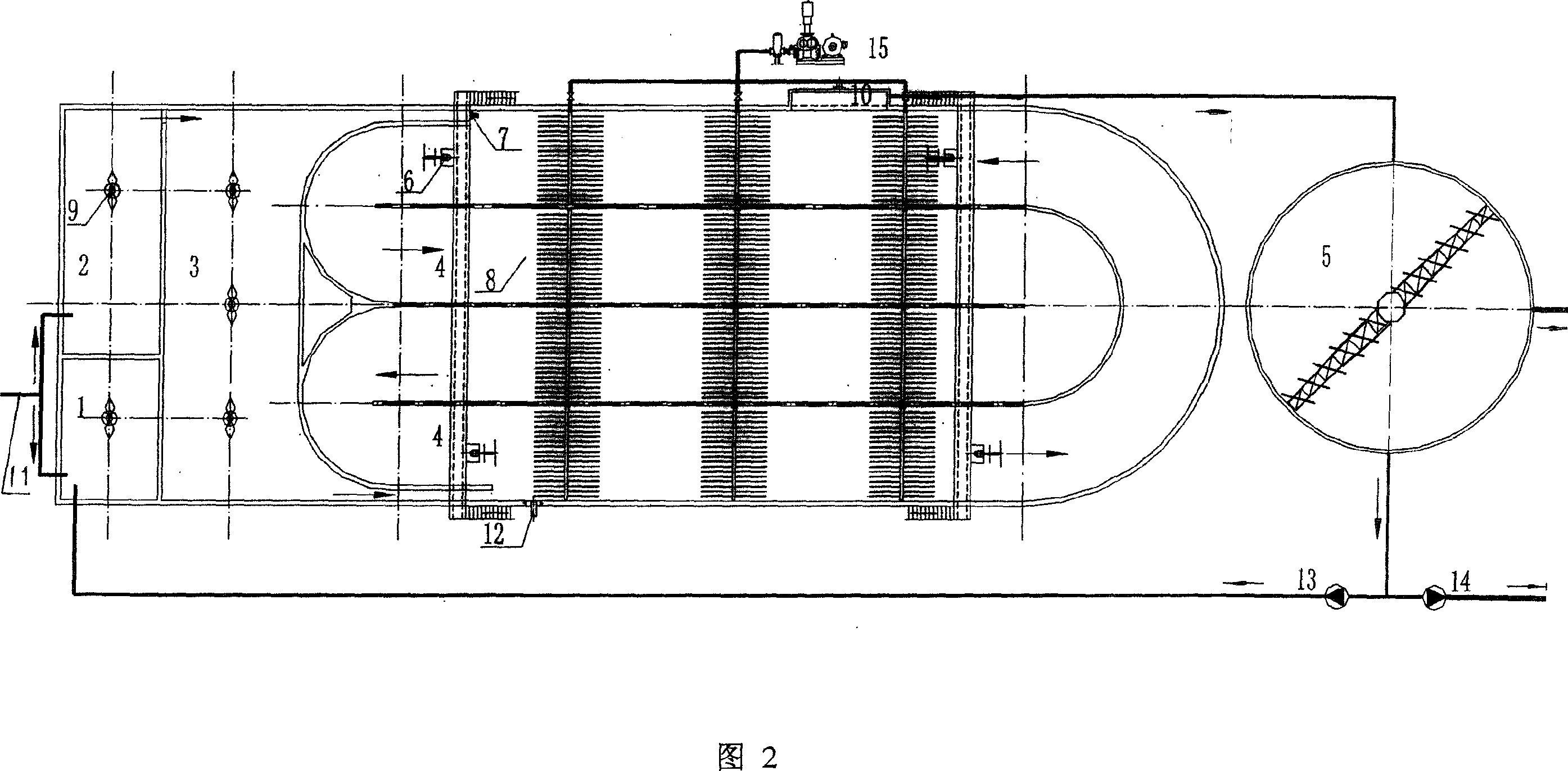

[0013] As shown in Figure 2, 1 pre-anoxic tank, 2 anaerobic tank, 3 anoxic tank, 4 oxidation ditch, 5 sedimentation tank, 6 underwater screw propeller, 7 internal return pump, 8 microporous aeration tube that can be lifted , 9 mixer, 10 outlet tank, 11 inlet pipe, 12 vent pipe, 13 sludge return pump, 14 residual sludge pump, 15 blower.

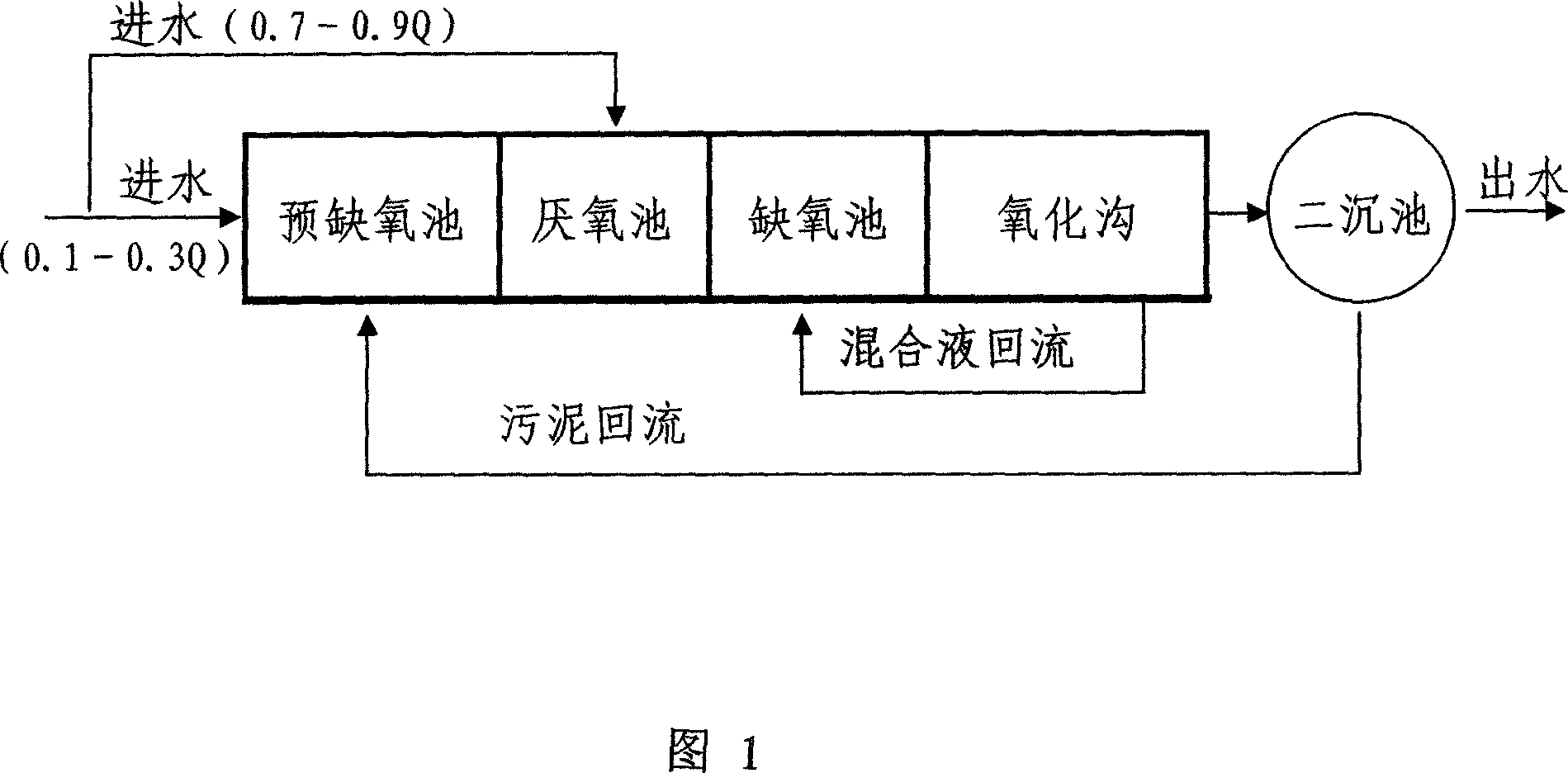

[0014] The improved biological reaction system shown in Figure 1 is to add a pre-denitrification tank (pre-anoxic tank) in front of the anaerobic tank to reduce the impact of nitrate in the returning sludge on anaerobic phosphorus release, and to inhibit the filamentous In order to solve the problem of insufficient carbon source for denitrification in the anoxic tank, the influent water is proportionally entered into the pre-anoxic tank and the anaerobic tank.

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com